Polyolefin-based adhesive agent composition

A composition and adhesive technology, applied in the direction of adhesives, battery pack parts, synthetic resin layered products, etc., can solve problems such as cracks and pinholes, and achieve maintenance of pot life, taking into account formability, and good pot life. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

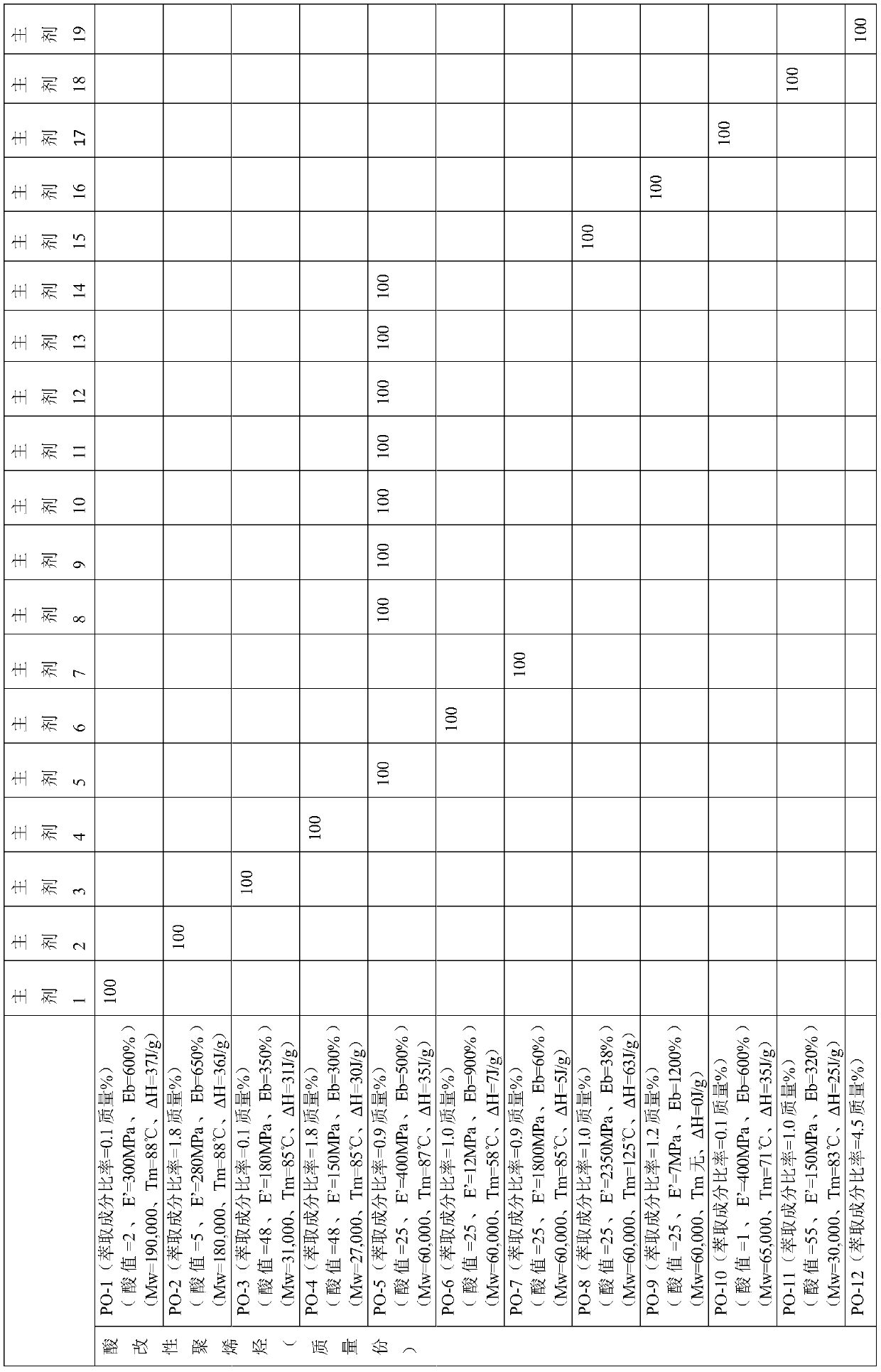

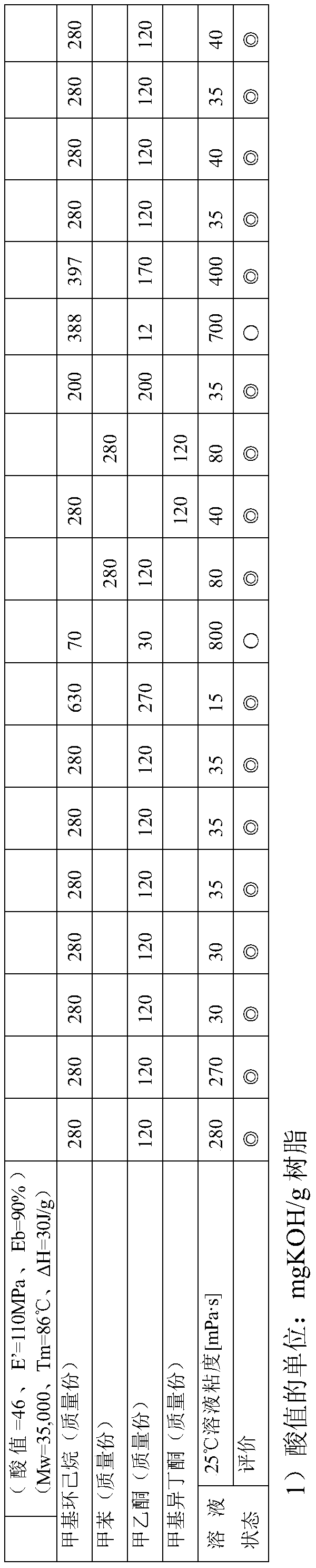

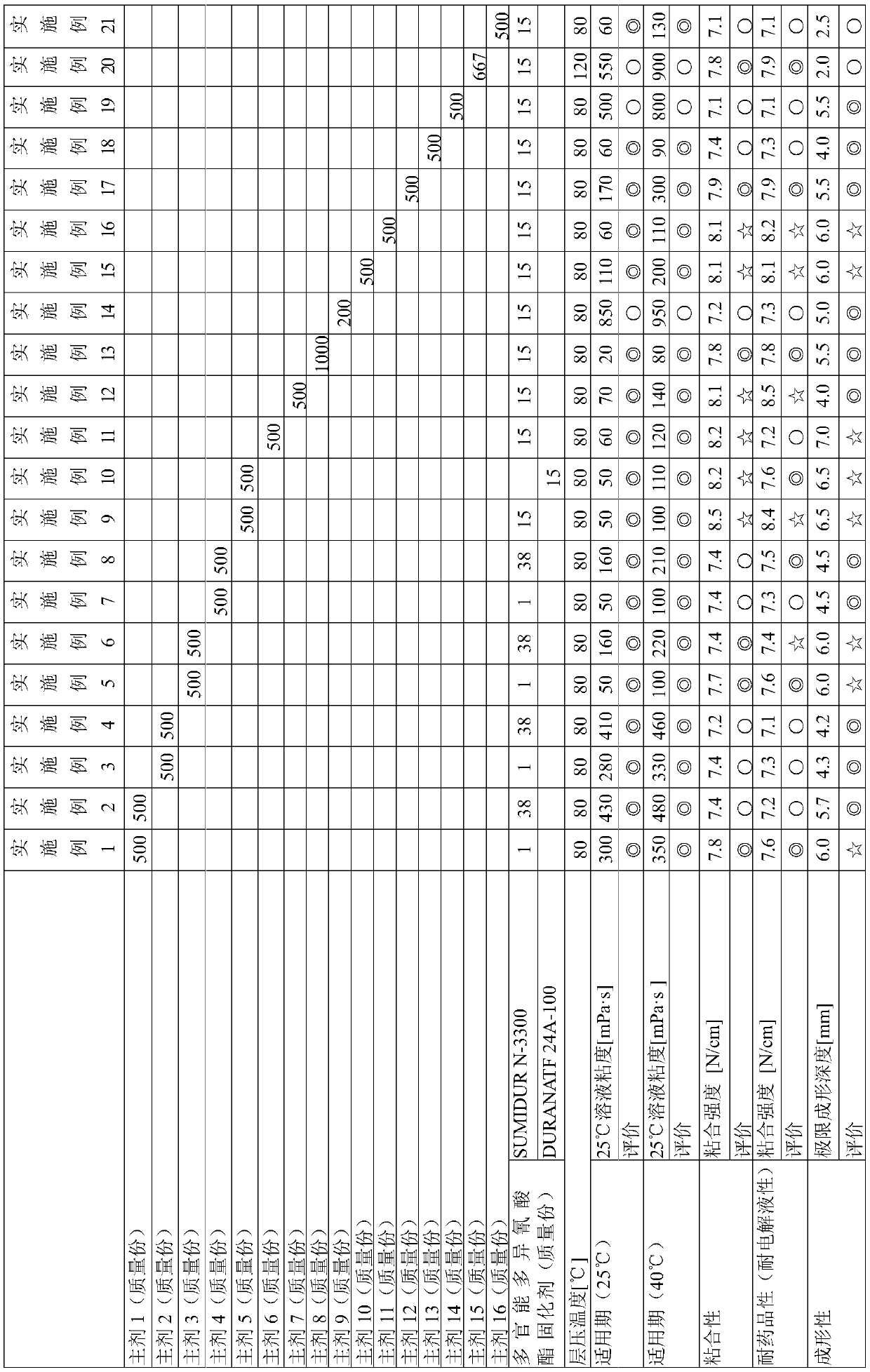

[0072] The following examples illustrate the present invention in more detail. It is just that the present invention is not limited to the examples. In the examples and comparative examples, the parts are simply described and represent parts by mass.

manufacture example 1

[0075] 100 parts by mass of propylene-ethylene copolymer (storage modulus at 25°C of 320 MPa, tensile elongation at break of 760% at 25°C), 233 parts by mass of toluene, and 1 part by mass of maleic anhydride were added to a 1-liter autoclave. . 0.5 parts by mass of di-tert-butyl peroxide, heated up to 140° C., and then further stirred for 1 hour (here, referred to as “reaction” for 1 hour). After that, the obtained reaction solution was cooled to 100° C., poured into a container containing 717 parts by mass of toluene and 950 parts by mass of methyl ethyl ketone preheated to 40° C. while stirring, cooled to 40° C., and stirred for 30 minutes. Further cooling to 25° C. precipitates the resin (here, the operation of pouring the reaction solution into a solvent such as methyl ethyl ketone while stirring and cooling to deposit the resin is referred to as “reprecipitation”). Thereafter, the acid-modified propylene-ethylene copolymer graft-polymerized with maleic anhydride is separ...

manufacture example 2

[0079] Except that the addition amount of maleic anhydride was changed to 3 parts by mass, the number of times of repulping was changed to 1 time, and the amount of methyl ethyl ketone input during repulping was changed to 1000 parts by mass, it was carried out in the same manner as in Production Example 1, thereby obtaining Maleic anhydride-modified propylene-ethylene copolymer of acid-modified polyolefin (PO-2, acid value 5 mgKOH / g resin, acetone-extracted component ratio 1.8% by mass, storage modulus at 25°C 280 MPa, Tensile elongation at break 650%, weight average molecular weight 180,000, Tm88°C, ΔH36J / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com