A kind of anti-high temperature and anti-saturated salt biomass lubricant and preparation method thereof

A biomass and high-temperature-resistant technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of drilling fluid foaming, decomposition failure, and difficulty in dispersing, and achieve rapid drilling, good stability, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

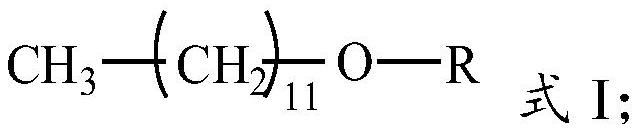

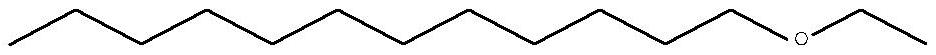

[0031] Add 1mol lauryl alcohol, 0.15mol ethyl chloride, 0.15mol sodium hydroxide and 0.25mol 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid catalyst into a reaction kettle with stirring, condensation and heating devices , stir to mix well. React under the conditions of 60°C and 200rpm for 16 hours, drop to room temperature, obtain ethyl lauryl ether after purification, and the structural formula of ethyl lauryl alcohol is:

[0032]

[0033] Terminal groups not given are methyl groups.

[0034] The mass concentration of 60 parts by weight of lauryl ether, the mass concentration of 37 parts by weight is the aqueous solution of potassium oleate of 10%, the sorbitan monooleate of 2 parts by weight and the high-viscosity sodium carboxymethyl cellulose (CMC) of 1 part by weight -HV) was added into a stirring tank, stirred at a temperature of 40° C. and a speed of 1200 r / min for 3 hours, and mixed uniformly to obtain a biomass lubricant.

Embodiment 2

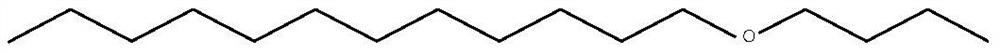

[0036] Add 1mol lauryl alcohol, 0.15mol chlorobutane, 0.15mol sodium hydroxide and 0.25mol 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid catalyst into a reaction kettle with stirring, condensation and heating devices , stir to mix well. React under the conditions of 80°C and 300rpm for 16 hours, drop to room temperature, and obtain butyl lauryl ether after purification. The structural formula of butyl lauryl alcohol is:

[0037]

[0038] Terminal groups not given are methyl groups.

[0039] The mass concentration of 80 parts by weight of butyl alcohol, 13 parts by weight of potassium oleate aqueous solution, 5 parts by weight of propylene glycol monostearate and 2 parts by weight of high-viscosity sodium carboxymethyl cellulose (CMC -HV) was added into a stirring tank, and stirred at a temperature of 60° C. at a speed of 1800 r / min for 1 hour to make it evenly mixed to obtain a biomass lubricant.

Embodiment 3

[0041] Add 1mol lauryl alcohol, 0.15mol chlorohexane, 0.15mol sodium hydroxide and 0.25mol 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid catalyst into a reaction kettle with stirring, condensation and heating devices , stir to mix well. React under the conditions of 100°C and 300rpm for 16 hours, drop to room temperature, obtain lauryl alcohol hexyl ether after purification, and the structural formula of said lauryl alcohol hexyl ether is:

[0042]

[0043] Terminal groups not given are methyl groups.

[0044]With the lauryl hexyl ether of 70 weight parts, the mass concentration of 25 weight parts is the potassium oleate aqueous solution of 20%, the diacetyl tartrate monoglyceride of 4 weight parts and the high viscosity sodium carboxymethyl cellulose (CMC) of 1 weight part -HV) was added into the stirring tank, stirred at a temperature of 50° C. and a speed of 1500 r / min for 2 hours, and mixed uniformly to obtain a biomass lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com