Air purification material and preparation method thereof

A technology of air purification materials and acidifiers, which is applied in the field of materials, can solve the problems of not being able to target VOC, the effect is not long-lasting, and it is difficult to realize civilian use, so as to achieve the effect of increasing the performance of repeated use, good slow-release effect, and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

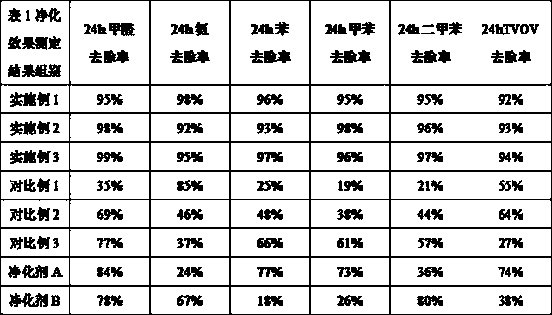

Examples

Embodiment 1

[0039] An air purification material, comprising an adsorption inner layer and a purification outer layer, wherein the adsorption inner layer comprises in parts by weight: 30 parts of montmorillonite, 10 parts of sepiolite, 0.1 part of acidulant, 10 parts of activated carbon, and a mass fraction of 10 parts of 2% foaming agent aqueous solution; the purified outer layer includes by weight: 1 part of titanium dioxide, 0.02 part of manganese dioxide, 5 parts of zinc nitrate, 1 part of bis-hexamethyltriamine, 1 part of fiber, water-based 2 parts of cationic polyurethane, 0.5 parts of sodium carboxymethyl cellulose, and 10 parts of aqueous foaming agent with a mass fraction of 2%.

[0040] Above-mentioned activated carbon is coconut shell powder activated carbon.

[0041] Above-mentioned acidulant is 1mol / L citric acid.

[0042] The above-mentioned foaming agent aqueous solution is an aluminum sulfate aqueous solution.

[0043] The above-mentioned titanium dioxide is anatase, and ...

Embodiment 2

[0060] An air purification material, comprising an adsorption inner layer and a purification outer layer, wherein the adsorption inner layer comprises in parts by weight: 50 parts of montmorillonite, 15 parts of sepiolite, 0.5 parts of acidulant, 30 parts of activated carbon, and a mass fraction of 40 parts of 6% foaming agent aqueous solution; the purified outer layer includes by weight: 3 parts of titanium dioxide, 0.1 part of manganese dioxide, 8 parts of zinc nitrate, 5 parts of bis-hexamethyltriamine, 5 parts of fiber, water-based 5 parts of cationic polyurethane, 0.8 part of sodium carboxymethyl cellulose, and 40 parts of 6% foaming agent aqueous solution by mass fraction.

[0061] The above-mentioned activated carbon is wood powder activated carbon.

[0062] Above-mentioned acidulant is 1.5mol / L citric acid.

[0063] Above-mentioned foaming agent aqueous solution is sodium bicarbonate aqueous solution.

[0064] The above-mentioned titanium dioxide is anatase, and the ...

Embodiment 3

[0081] An air purification material, comprising an adsorption inner layer and a purification outer layer, wherein the adsorption inner layer comprises in parts by weight: 40 parts of montmorillonite, 12 parts of sepiolite, 0.3 parts of acidulant, 20 parts of activated carbon, and a mass fraction of 35 parts of 2% foaming agent aqueous solution; the purified outer layer includes by weight: 2 parts of titanium dioxide, 0.08 part of manganese dioxide, 6 parts of zinc nitrate, 4 parts of bis-hexamethyltriamine, 3 parts of fiber, water-based 3 parts of cationic polyurethane, 0.7 parts of sodium carboxymethyl cellulose, and 35 parts of aqueous foaming agent with a mass fraction of 4%.

[0082] Above-mentioned activated carbon is coconut shell powder activated carbon.

[0083] The above-mentioned acidifying agent is 0.05mol / L sulfuric acid.

[0084] Above-mentioned foaming agent aqueous solution is sodium bicarbonate aqueous solution.

[0085] The above-mentioned titanium dioxide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com