Tin diselenide with nano flower structure and preparation method thereof

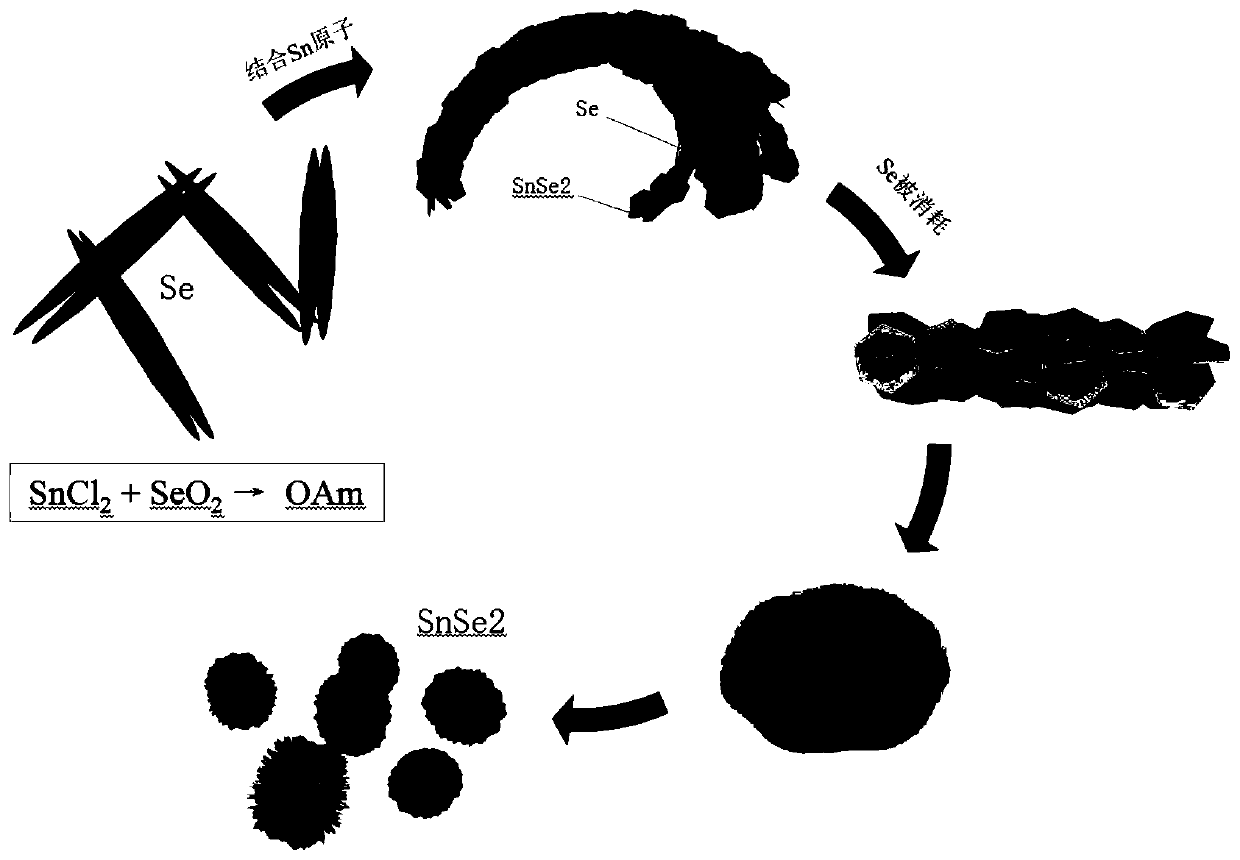

A technology of tin diselenide and nanoflowers, which is applied in the direction of binary selenium/tellurium compounds, nanotechnology, nanotechnology, etc., can solve the problem of small specific surface area of tin diselenide, achieve uniform size, small size, prevent The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052]Heat 68mL oleylamine to 70°C in a heat-collecting magnetic stirrer, add 2.4mmol selenium dioxide and stir until a clear solution, add 2.4mmol stannous chloride, add 2.5mL n-dodecanethiol, stir until completely dissolved , immediately put the mixture into a stainless steel autoclave lined with 100mL polytetrafluoroethylene, seal it and put it in a constant temperature oven, heat it to 180°C, and keep it warm for 36h. After the reaction, take out the autoclave and let it cool down to room temperature naturally. The precipitate was collected by centrifugation, and was repeatedly centrifuged and washed 4 times with a toluene / ethanol mixture, and the precipitate obtained after centrifugation was dried in a vacuum oven at 60° C. for 6 hours to obtain a tin diselenide nanoflower material.

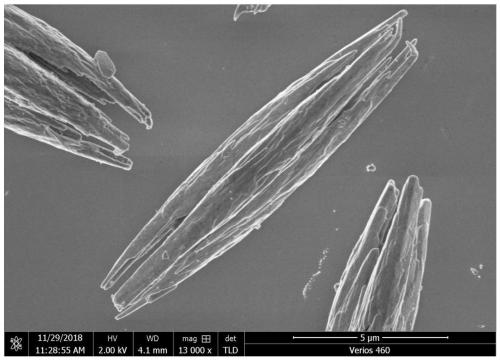

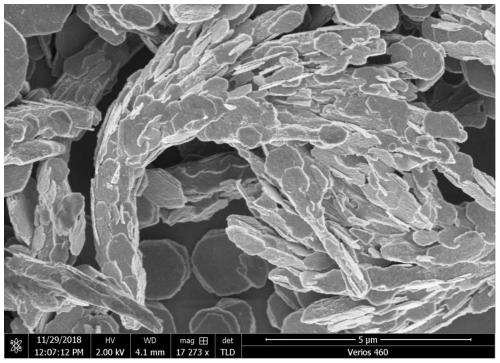

[0053] Carry out XRD, SEM, TEM analysis to embodiment 1 gained process tin diselenide, and final product tin diselenide nano flower material, the result is as follows Figure 2-Figure 10 sho...

Embodiment 2

[0063] Heat 68mL oleylamine to 70°C in a heat-collecting magnetic stirrer, add 0.8mmol selenium dioxide and stir until a clear solution, add 0.8mmol stannous chloride, add 0.8mL n-dodecanethiol, stir until completely dissolved , immediately put the mixture into a stainless steel autoclave lined with 100mL polytetrafluoroethylene, seal it and put it in a constant temperature oven, heat it to 180°C, and keep it warm for 24 hours. After the reaction, take out the autoclave and let it cool down to room temperature naturally. The precipitate was collected by centrifugation, and was repeatedly centrifuged and washed 4 times with a toluene / ethanol mixture, and the precipitate obtained after centrifugation was dried in a vacuum oven at 60° C. for 6 hours to obtain a tin diselenide nanoflower material.

Embodiment 3

[0065] Heat 68mL of oleylamine to 70°C in a heat-collecting magnetic stirrer, add 1.6mmol of selenium dioxide and stir to a clear solution, add 1.6mmol of stannous chloride, add 1.6mL of n-dodecanethiol, and stir until completely dissolved , immediately put the mixture into a stainless steel autoclave lined with 100mL polytetrafluoroethylene, seal it and put it in a constant temperature oven, heat it to 180°C, and keep it warm for 48h. After the reaction, take out the autoclave and let it cool down to room temperature naturally. The precipitate was collected by centrifugation, and was repeatedly centrifuged and washed 4 times with a toluene / ethanol mixture, and the precipitate obtained after centrifugation was dried in a vacuum oven at 60° C. for 6 hours to obtain a tin diselenide nanoflower material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com