Method for increasing amount of hydrogen produced through mixing of kitchen waste and blue-green algae through pretreatment

A technology for kitchen waste and pretreatment, which is applied in the directions of biosynthesis and fermentation to achieve the effect of promoting hydrogen production by anaerobic fermentation, with simple process and improving hydrogen production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

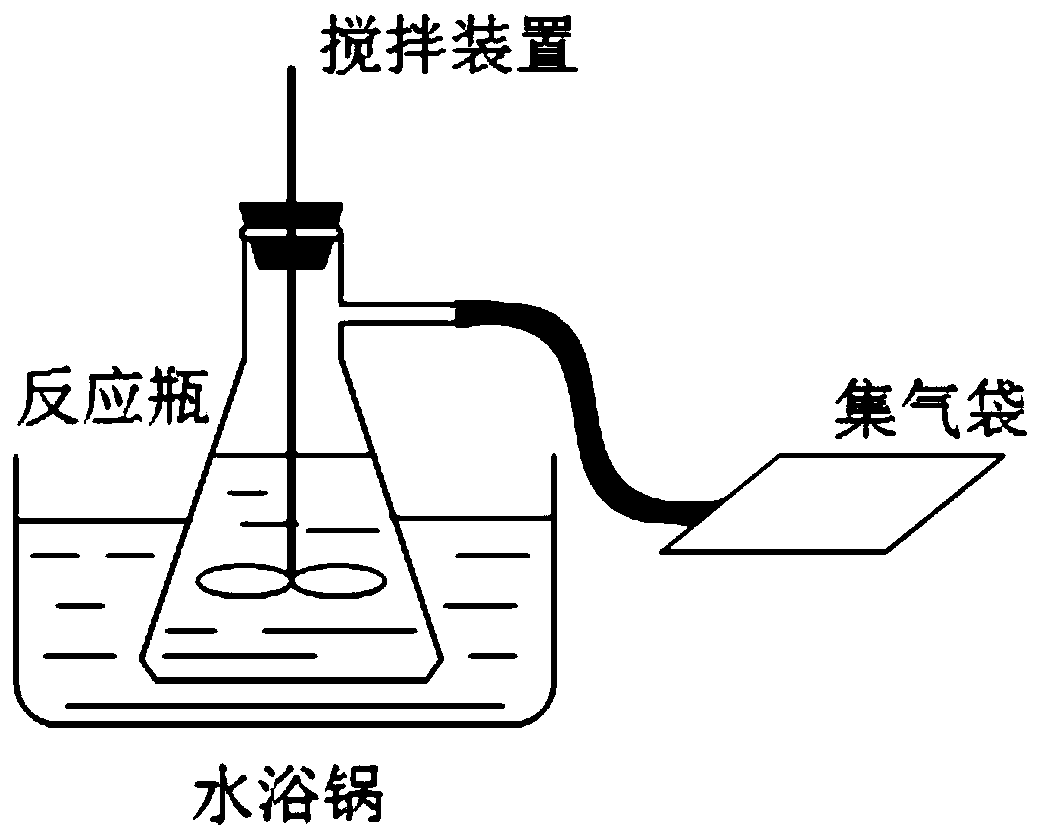

[0043] The schematic diagram of the experimental device is as follows: figure 1 shown. Specific steps are as follows:

[0044] (1) Heat treatment of anaerobic granular sludge: heat treatment temperature of anaerobic granular sludge is 120°C, and treatment time is 10 minutes;

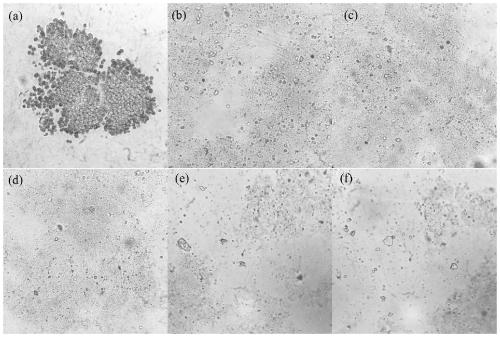

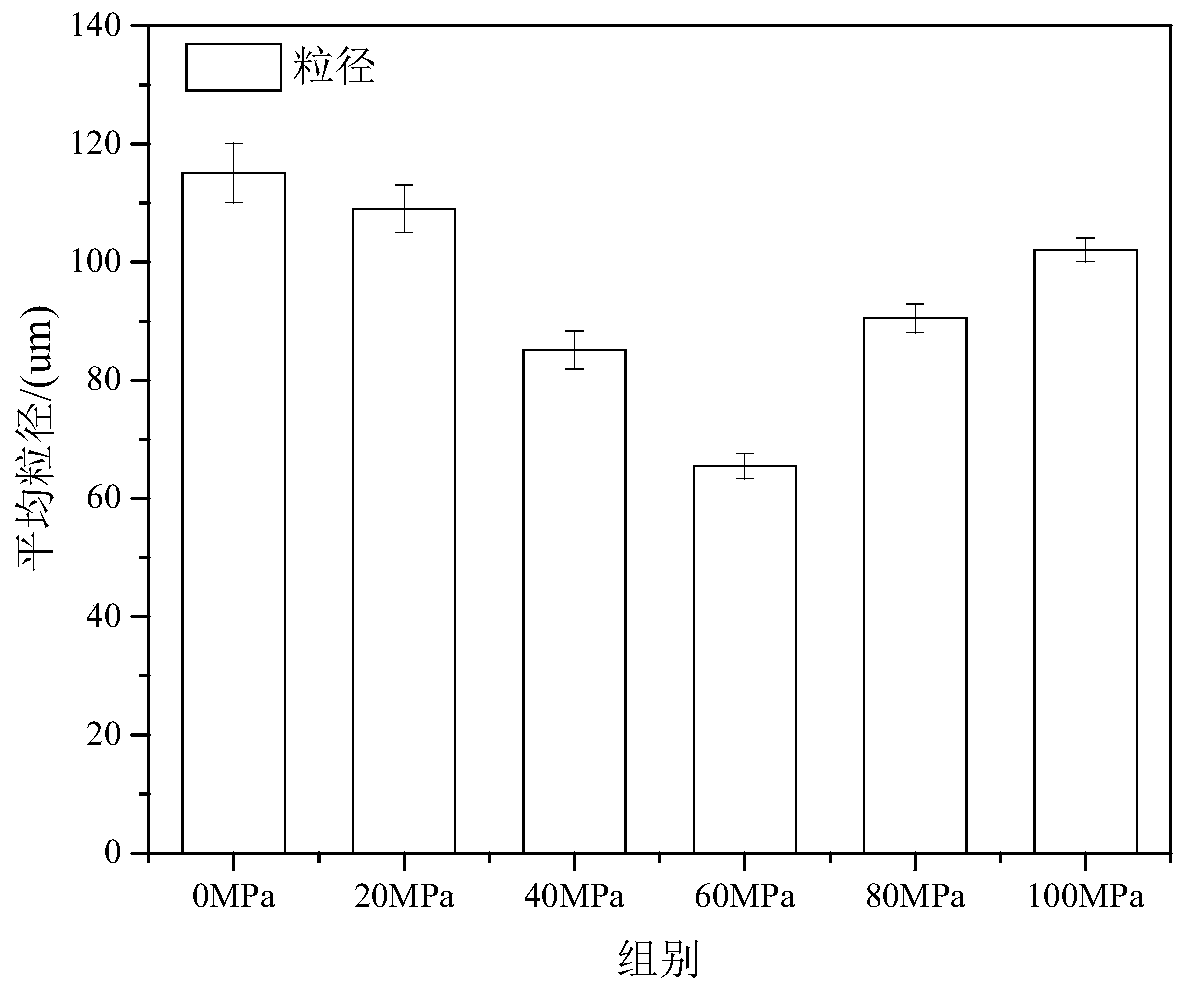

[0045] (2) Pretreatment of cyanobacteria by high-pressure homogenization: first filter the cyanobacteria with a 100-mesh sieve to remove large particles or sticky substances, and then carry out high-pressure homogenization and crushing at a pressure of 60 MPa, and the number of homogenization is 1 time. See the microscopic morphology, average particle size, SCOD dissolution effect and cracking energy efficiency of cyanobacteria after high-pressure homogenization. Figure 2-5 .

[0046] (3) Mix the cyanobacteria and kitchen waste after high-pressure homogenization in step (2) as the fermentation substrate: the mixing ratio is TS 1:4;

[0047] (4) Mix the heat-treated anaerobic granular sludge in step ...

Embodiment 2

[0049] Example 2: Effects of different homogeneous pressures on the hydrogen production performance of mixed fermentation

[0050] Adopt the method of embodiment 1 to carry out anaerobic fermentation, difference is only: high-pressure homogeneous pressure is respectively: 20, 40, 80 and 100MPa, other conditions are the same as embodiment 1. See the microscopic morphology, average particle size, SCOD dissolution effect and cracking energy efficiency of cyanobacteria after high-pressure homogenization. Figure 2-5 ; After mixed fermentation, the cumulative hydrogen production, organic matter degradation rate and liquid phase end product concentration changes are shown in Figure 6-9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com