NO2 gas sensitive element based on rGO-SnO2 nanometer composite material and preparation method thereof

A nanocomposite material and gas sensor technology, applied in the field of graphene-metal oxide composite gas sensor, can solve the problems of poor selectivity, high working temperature, low sensitivity, etc., and achieve good selectivity and stability, resistance The effect of low rate and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

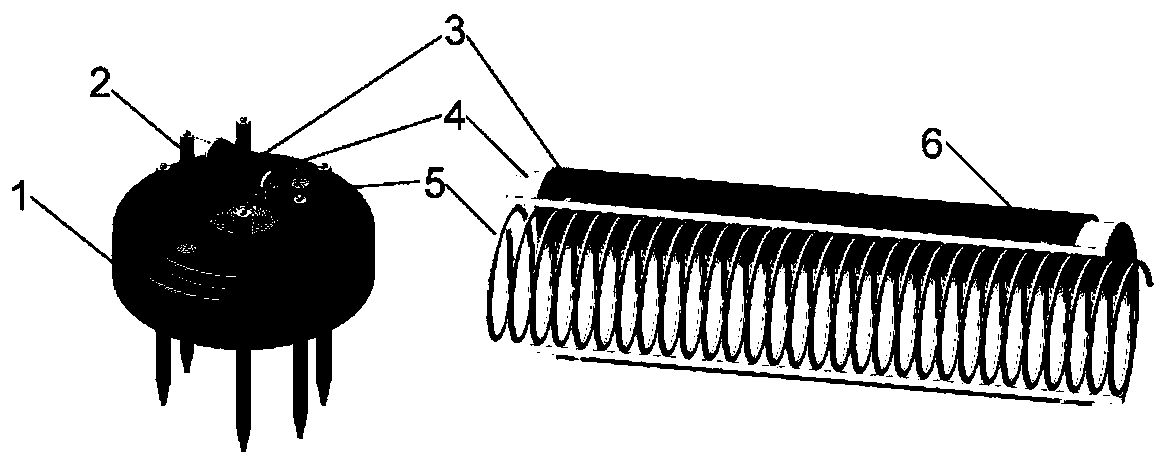

[0037] The present embodiment based on rGO-SnO 2 NO of nanocomposites 2 Gas sensor, its structure diagram is as follows figure 1 As shown, including base 1, platinum lead 2, rGO-SnO 2 Nanocomposite material coating 3, ceramic tube 4, heating wire 5, and gold electrode 6 are composed of six parts. The gold electrode 6 is wound on the surface of the ceramic tube 4 and welded to form a ceramic electrode. The platinum lead wire 2 is welded on the surface of the gold electrode 6 and heated Wire 5 traverses in ceramic tube 4, rGO-SnO 2 The nanocomposite material layer 3 is coated on the entire surface of the ceramic tube 4 and the gold electrode 6, and the heating wire 5 and the platinum lead 2 are sequentially welded on the base 1 to form an rGO-SnO 2 NO of nanocomposites 2 gas sensor.

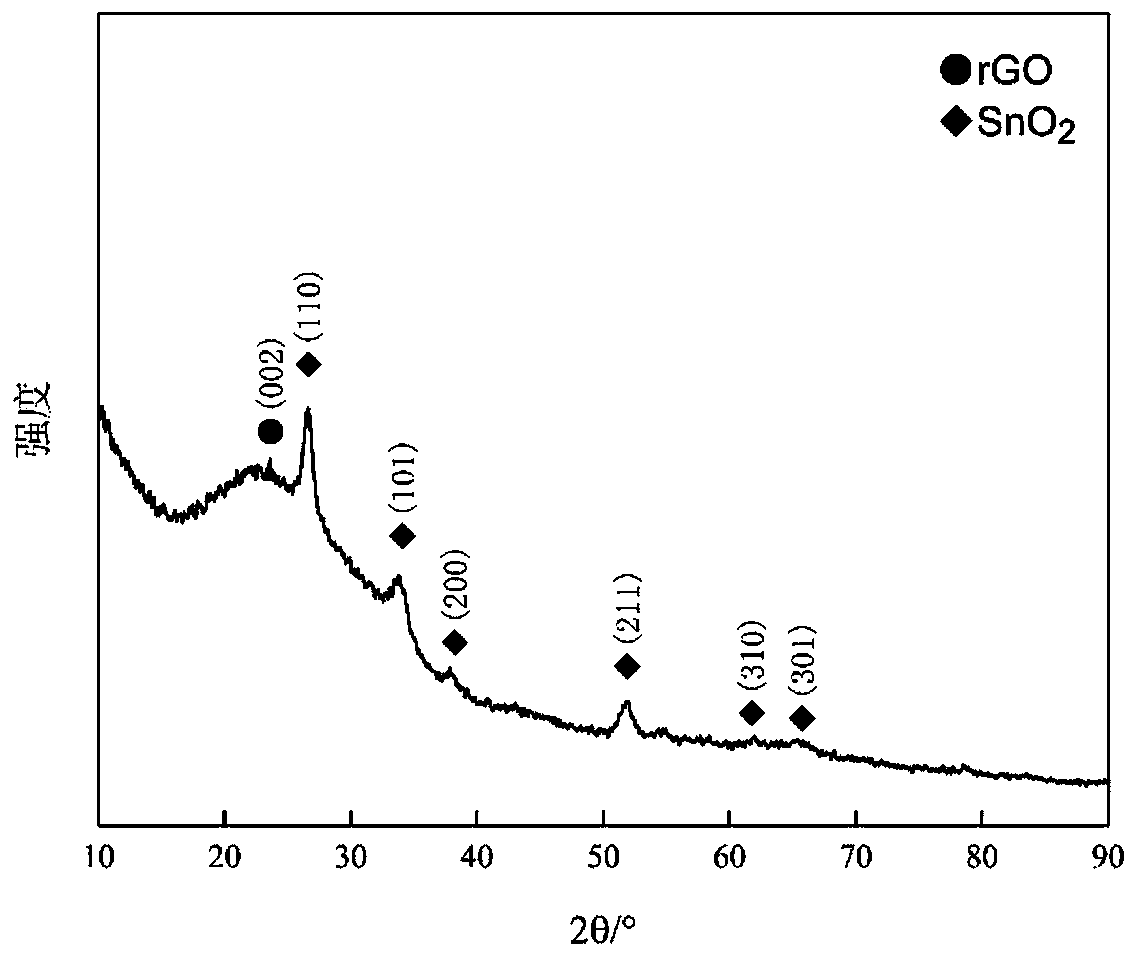

[0038] The rGO-SnO 2 The X-ray diffraction pattern of the nanocomposite is as figure 2 As shown, the rGO-SnO 2 X-ray diffraction peaks in nanocomposites including SnO 2 and diffraction pe...

Embodiment 2

[0050] The present embodiment based on rGO-SnO 2 NO of nanocomposites 2 Gas sensor, its structure diagram is as follows figure 1 As shown, including base 1, platinum lead 2, rGO-SnO 2 Nanocomposite material coating 3, ceramic tube 4, heating wire 5, and gold electrode 6 are composed of six parts. The gold electrode 6 is wound on the surface of the ceramic tube 4 and welded to form a ceramic electrode. The platinum lead wire 2 is welded on the surface of the gold electrode 6 and heated Wire 5 traverses in ceramic tube 4, rGO-SnO 2 The nanocomposite material layer 3 is coated on the entire surface of the ceramic tube 4 and the gold electrode 6, and the heating wire 5 and the platinum lead 2 are sequentially welded on the base 1 to form an rGO-SnO 2 NO of nanocomposites 2 gas sensor.

[0051] A rGO-SnO-based 2 NO of nanocomposites 2 The preparation method of the gas sensor is carried out according to the following steps:

[0052] ① Weigh 60mL of absolute ethanol and 60mL ...

Embodiment 3

[0058] The present embodiment based on rGO-SnO 2 NO of nanocomposites 2 Gas sensor, its structure diagram is as follows figure 1 As shown, including base 1, platinum lead 2, rGO-SnO 2 Nanocomposite material coating 3, ceramic tube 4, heating wire 5, and gold electrode 6 are composed of six parts. The gold electrode 6 is wound on the surface of the ceramic tube 4 and welded to form a ceramic electrode. The platinum lead wire 2 is welded on the surface of the gold electrode 6 and heated Wire 5 traverses in ceramic tube 4, rGO-SnO 2 The nanocomposite material layer 3 is coated on the entire surface of the ceramic tube 4 and the gold electrode 6, and the heating wire 5 and the platinum lead 2 are sequentially welded on the base 1 to form an rGO-SnO 2 NO of nanocomposites 2 gas sensor.

[0059] A rGO-SnO-based 2 NO of nanocomposites 2 The preparation method of the gas sensor is carried out according to the following steps:

[0060] ① Weigh 60 mL of absolute ethanol and 60 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com