Metal soft magnetic powder core preparation method based on organic/inorganic composite insulation process

An inorganic composite and metal soft magnetic technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as high hysteresis loss, high eddy current loss, and poor DC bias performance, and achieve non-phase Capacitance problems, improve the connection strength, reduce the effect of hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

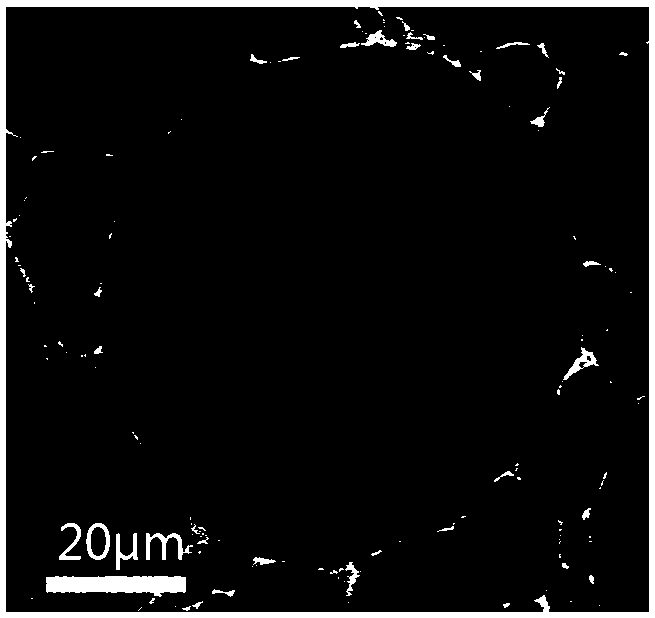

Image

Examples

Embodiment 1

[0030] (1) Add 300g of sendust magnetic powder into a solution of 0.6g of epoxy resin diluted with 40g of acetone for ultrasonic dispersion, and then dry at 60°C for 30 minutes to obtain sendust magnetic powder coated with organic insulation;

[0031] (2) Mix 15g of absolute ethanol, 3g of deionized water, 15g of tetraethyl orthosilicate, and 1.5g of kH550 silane coupling agent to prepare an inorganic insulating coating agent;

[0032] (3) Mix the organic insulating coated sendust magnetic powder obtained in step (1) with the inorganic insulating coating agent obtained in step (2), stir mechanically to make a mixed solution, take 0.25g of ammonia water and dilute with 3g of deionized water Finally, add it into the mixed solution at a dropping rate of 0.5ml / min, and stir at the same time. After the dropwise addition is completed, continue stirring for 1 hour, so that the reaction of hydrolyzing ethyl orthosilicate to generate nano-silicon oxide is fully carried out, and the kH55...

Embodiment 2

[0041] (1) Add 300g of iron-silicon magnetic powder into a solution of 0.3g of epoxy resin diluted with 40g of acetone and ultrasonically disperse, and then dry at 60°C for 30 minutes to obtain organic insulating-coated iron-silicon magnetic powder;

[0042] (2) 15g of absolute ethanol, 3g of deionized water, 9g of tetraethyl orthosilicate, and 1.5g of kH550 silane coupling agent are mixed to prepare an inorganic insulating coating agent;

[0043] (3) Mix the ferrosilicon magnetic powder obtained in step (1) after organic insulation coating with the inorganic insulation coating agent obtained in step (2), stir it mechanically to make a mixed solution, take 0.25g of ammonia water and dilute it with 3g of deionized water , add it into the mixed solution at a dropping rate of 0.5ml / min, and stir at the same time. After the dropping is completed, continue to stir for 1h, so that the reaction of hydrolyzing ethyl orthosilicate to generate nano-silicon oxide is fully carried out, and...

Embodiment 3

[0052] (1) Add 300 g of iron-nickel magnetic powder to a solution of 0.9 g of epoxy resin diluted with 40 g of acetone for ultrasonic dispersion, and then dry at 60° C. for 30 minutes to obtain organic insulating-coated iron-nickel magnetic powder;

[0053] (2) Mix 15g of absolute ethanol, 3g of deionized water, 3g of tetraethyl orthosilicate, and 1.5g of kH550 silane coupling agent to prepare an inorganic insulating coating agent;

[0054] (3) After mixing the organic insulating coated iron-nickel magnetic powder obtained in step (1) with the inorganic insulating coating agent obtained in step (2), stir mechanically to make a mixed solution, take 0.25g of ammonia water and dilute it with 3g of deionized water , add it into the mixed solution at a dropping rate of 0.5ml / min, and stir at the same time. After the dropping is completed, continue to stir for 1h, so that the reaction of hydrolyzing ethyl orthosilicate to generate nano-silicon oxide is fully carried out, and the amin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com