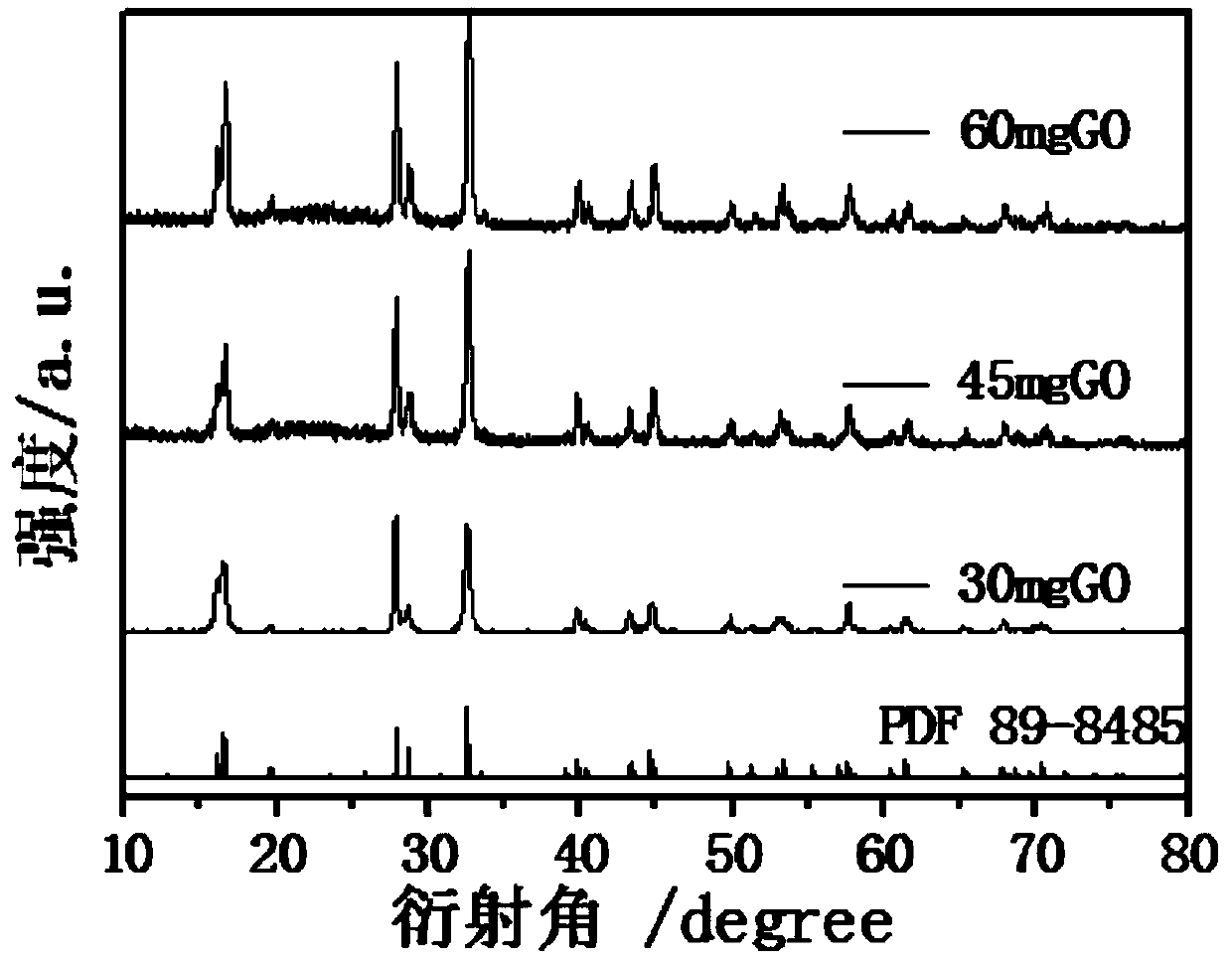

Sodium vanadium fluorophosphate/graphene composite, preparation method thereof and use thereof

A technology of sodium vanadyl fluorophosphate and sodium vanadyl phosphate, which is applied in the field of sodium vanadyl fluorophosphate/graphene composite and preparation, can solve problems such as poor conductivity of sodium vanadyl fluorophosphate, and achieves favorable ionic and structural stability. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The second of the present invention provides a preparation method of sodium vanadyl fluorophosphate / graphene composite, comprising:

[0040] (1) graphene is dispersed in deionized water to obtain graphene oxide aqueous solution;

[0041] And the trivalent vanadium compound, phosphoric acid / phosphoric acid compound, sodium fluoride, ethanol and acetone are mixed uniformly according to the preset ratio to obtain a mixed solution;

[0042] (2) After mixing the graphene oxide aqueous solution and the mixed solution in a set ratio, they are placed in an autoclave at a temperature of 120° C. for hydrothermal reaction;

[0043] (3) The product after hydrothermal reaction in step (2) is successively washed, centrifuged and dried to obtain sodium vanadyl fluorophosphate / graphene composite (Na 3 (VOPO 4 ) 2 F).

[0044] Preferably, the mixed solution in the above step (1) is vanadium acetylacetonate, phosphoric acid, sodium fluoride, ethanol and acetone;

[0045] Preferably,...

Embodiment 1

[0055] Take 150 mg of graphene oxide and disperse it in 15 g of deionized water, and use an ultrasonic cell pulverizer to sonicate for 40 minutes to obtain a uniformly dispersed graphene oxide aqueous solution; take 359 mg of vanadium acetylacetonate, 104 μL of phosphoric acid (85%, 14.4968 moles per liter), 71.5 mg Dissolve sodium fluoride in a mixed solution of 3mL ethanol and 1mL acetone, then add 3g of the above-mentioned graphene oxide aqueous solution to the mixed solution, mix well, transfer it to a 25mL polytetrafluoroethylene reactor, and place it in a constant temperature oven at 120°C After keeping for 10 hours, the reacted samples were taken out, washed three times with ethanol and deionized water respectively, centrifuged and then dried to obtain the sodium vanadyl fluorophosphate / graphene composite.

[0056] Apply the sodium vanadyl fluorophosphate / graphene composite prepared above to electrode materials, add conductive agent acetylene black, and binder polyvinyli...

Embodiment 2

[0058] Take 150 mg of graphene oxide and disperse it in 15 g of deionized water, and use an ultrasonic cell pulverizer to sonicate for 40 minutes to obtain a uniformly dispersed graphene oxide aqueous solution; take 359 mg of vanadium acetylacetonate, 104 μL of phosphoric acid (85%, 14.4968 moles per liter), 71.5 mg Dissolve sodium fluoride in a mixed solution of 3mL ethanol and 1mL acetone, then add 4.5g of the above-mentioned graphene oxide aqueous solution to the mixed solution, mix it uniformly, transfer it to a 25mL polytetrafluoroethylene reactor, and place it in a constant temperature oven at 120 Keep at ℃ for 10 hours, take out the reacted sample, wash with ethanol and deionized water three times respectively, centrifuge and dry to obtain sodium fluorovanadyl phosphate / graphene composite.

[0059] Apply the sodium vanadyl fluorophosphate / graphene composite prepared above to electrode materials, add conductive agent acetylene black, and binder polyvinylidene fluoride at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com