Lily temperature-changing drying method

A temperature-changing drying and drying technology, which is applied in food drying, food science, food preservation, etc., can solve the problems of volatile oil color darkening and affecting product appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

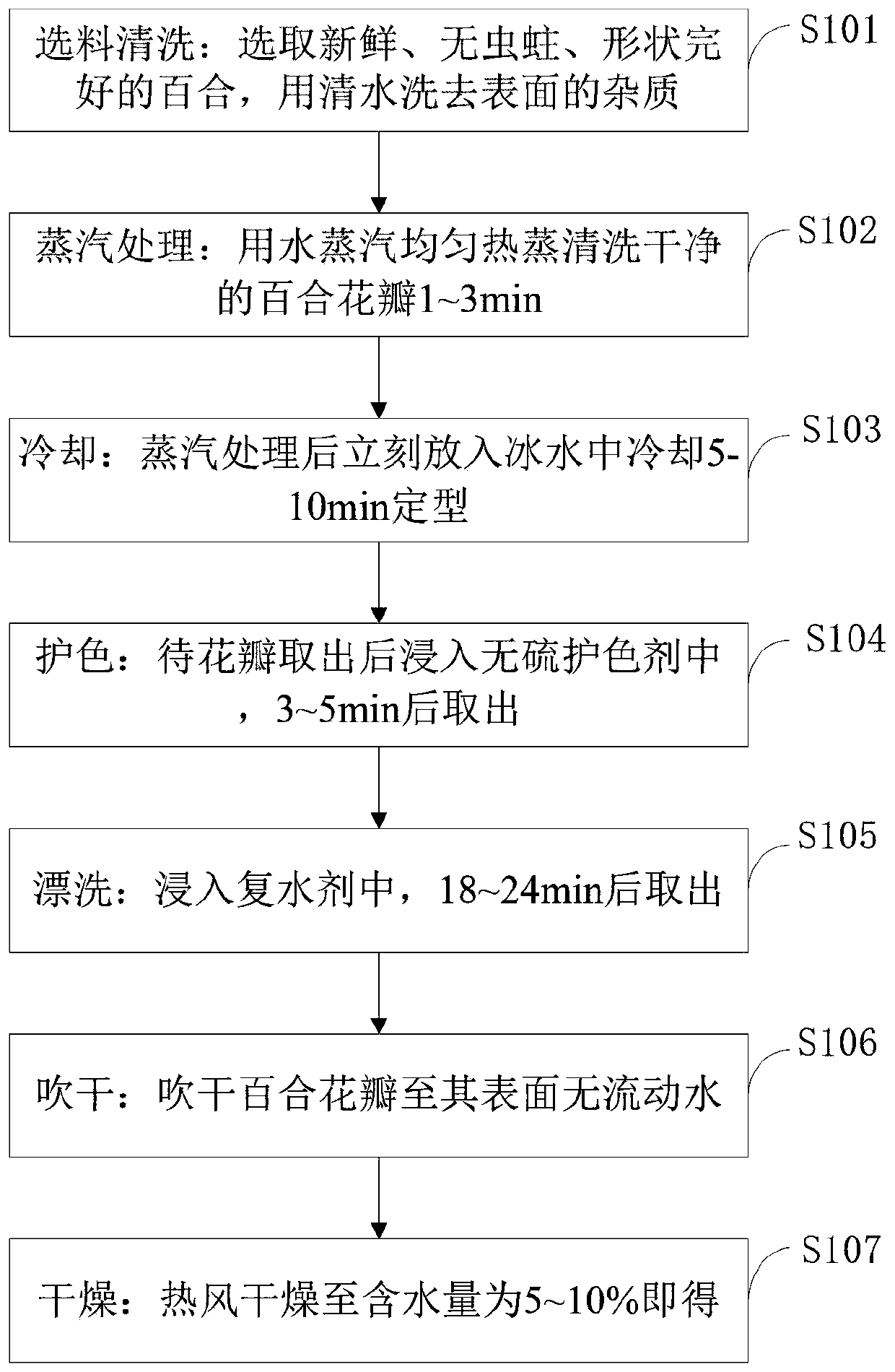

[0062] (1) Material selection and cleaning: select fresh, moth-free, and well-shaped lilies, and wash off surface impurities with clean water;

[0063] (2) Steam treatment: evenly steam the cleaned lily petals with water steam for 2 minutes;

[0064] (3) Cooling: After steam treatment, put it into ice water and cool it for 7 minutes to finalize the shape;

[0065] (4) Color protection: After the petals are taken out, immerse in a sulfur-free color protection agent (100ml of water contains 0.63g of sodium chloride, 0.32g of ascorbic acid, 0.28g of L-cysteine, and 0.75g of citric acid), for 3 minutes after taking out;

[0066] (5) Rinse: soak in rehydrating agent (100ml water contains 13.8g maltodextrin, 7.4g lactose, 9.1g trehalose), take it out after 18min;

[0067] (6) Blow-drying: Blow-dry the lily petals until there is no flowing water on its surface;

[0068] (7) Drying: Lily was dried at 92°C for 18 minutes, at 70°C for 1.6 hours, and at 54°C for 7 hours.

[0069] After...

Embodiment 2

[0071] (1) Material selection and cleaning: select fresh, moth-free, and well-shaped lilies, and wash off surface impurities with clean water;

[0072] (2) Steam treatment: evenly steam the cleaned lily petals with water steam for 3 minutes;

[0073] (3) Cooling: After steam treatment, put it into ice water and cool it for 10 minutes to finalize the shape;

[0074] (4) Color protection: After the petals are taken out, immerse in a sulfur-free color protection agent (100ml of water contains 0.68g of sodium chloride, 0.25g of ascorbic acid, 0.40g of L-cysteine, and 0.86g of citric acid), for 5 minutes after taking out;

[0075] (5) Rinse: soak in rehydrating agent (100ml of water contains 14.7g of maltodextrin, 5.9g of lactose, 8.9g of trehalose), take it out after 24min;

[0076] (6) Blow-drying: Blow-dry the lily petals until there is no flowing water on its surface;

[0077] (7) Drying: Lily is dried at 100°C for 30 minutes, at 75°C for 2 hours, and at 60°C for 8 hours.

...

Embodiment 3

[0080] (1) Material selection and cleaning: select fresh, moth-free, and well-shaped lilies, and wash off surface impurities with clean water;

[0081] (2) Steam treatment: evenly steam the cleaned lily petals with water steam for 1 min;

[0082] (3) Cooling: After steam treatment, put it into ice water and cool it for 5 minutes to finalize the shape;

[0083] (4) Color protection: After the petals are taken out, immerse in a sulfur-free color protection agent (100ml of water contains 0.65g of sodium chloride, 0.41g of ascorbic acid, 0.33g of L-cysteine, and 0.80g of citric acid), for 3 minutes after taking out;

[0084] (5) Rinse: soak in rehydrating agent (100ml of water contains 15.1g of maltodextrin, 7.8g of lactose, 10.2g of trehalose), take it out after 18min;

[0085] (6) Blow-drying: Blow-dry the lily petals until there is no flowing water on its surface;

[0086] (7) Drying: Lily is dried at 100°C for 30 minutes, at 75°C for 2 hours, and at 60°C for 8 hours.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com