Wide-load denitration method and device

A load and denitrification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of SCR denitrification system inoperability, induced draft fan overload operation, air preheater blockage and corrosion, etc., to achieve outstanding environmental and environmental protection Social benefits, avoiding clogging and corrosion, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment 1 provides a wide-load denitrification method, which will contain NO X The flue gas is passed into the low-temperature plasma reaction device, and the NO X Add a preset proportion of O to the flue gas 2 , using plasma technology to react the gas in a low-temperature plasma device to obtain N 2 , NO 2 , N 2 o 5 , get NO 2 , N 2 o 5 Pass into the absorption device and react with water to generate HNO 3 、HNO 2 And removal, the purified flue gas is discharged into the atmosphere through the chimney;

[0035] Among them, NO X X in is 1 or 2.

[0036] NO XThe conversion efficiency is related to the power of the plasma power supply in the low-temperature plasma device. Preferably, the power of the plasma power supply in the low-temperature plasma device is 1 to 40W / Nm 3 , preferably 1-5W / Nm 3 .

[0037] NO in boiler flue gas X Mainly composed of NO and NO 2 composition, where NO accounts for NO X More than 95% of the total is its main componen...

Embodiment 2

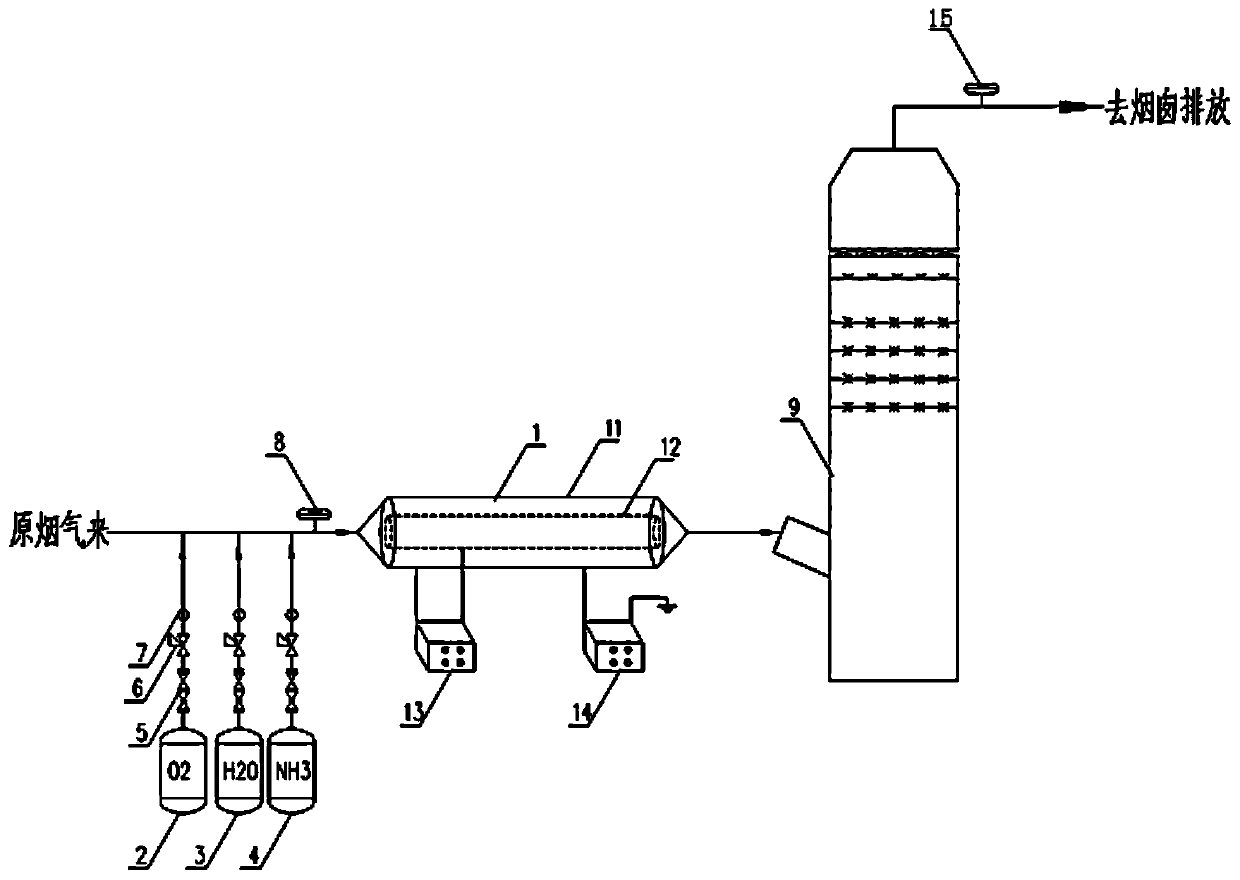

[0077] see figure 1 , this embodiment provides a wide-load denitrification device, including: a gas delivery system, a first flue gas emission continuous monitoring system 8, a low-temperature plasma reaction device 1, a second flue gas emission continuous monitoring system 15, and an absorption device. The absorption device of the embodiment adopts the wet desulfurization device 9;

[0078] Among them, the flue gas enters the low-temperature plasma reaction device 1 through the gas delivery system for reaction, and the reacted gas enters the wet desulfurization device 9 for a synergistic reaction and then is discharged into the atmosphere through the chimney;

[0079] After the gas delivery system and before the low-temperature plasma reaction device 1, a first flue gas emission continuous monitoring system 8 is arranged, and after the absorption device, a second flue gas emission continuous monitoring system 15 is arranged;

[0080] The gas delivery system includes O 2 Gas t...

Embodiment 3

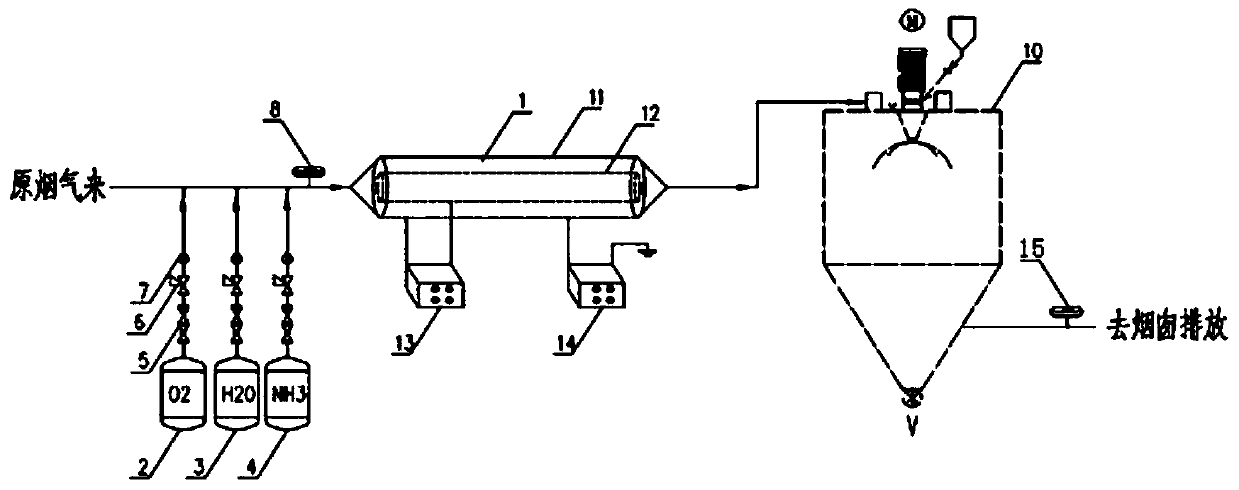

[0088] refer to figure 2 The difference between this embodiment and Embodiment 1 is that in this embodiment, the absorption device adopts a semi-dry desulfurization device 10, and only the top of the tower of the semi-dry desulfurization device 10 is provided with nozzles for spraying desulfurization slurry. The dry desulfurization device 10 is used to provide a reaction environment for free water, which is used to cooperatively absorb and remove NO produced by the low-temperature plasma reaction device 1 2 , N 2 o 5 , and finally achieve NO X The ultra-low emission, the second is used for the removal of sulfur compounds in the flue gas.

[0089] In summary, the method and device of the present invention completely replace the traditional SCR denitrification technology by using plasma technology. Compared with the traditional SCR denitrification technology, it is not affected by unit load and flue gas temperature, and the denitrification efficiency can reach more than 90%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com