Method for preparing nanogold array with catalytic performance through rigid crosslinking

A catalytic performance, nano-gold technology, applied in the field of nano-gold arrays, can solve the problems of few application reports of two-dimensional nano-gold arrays, and achieve the effect of being beneficial to catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

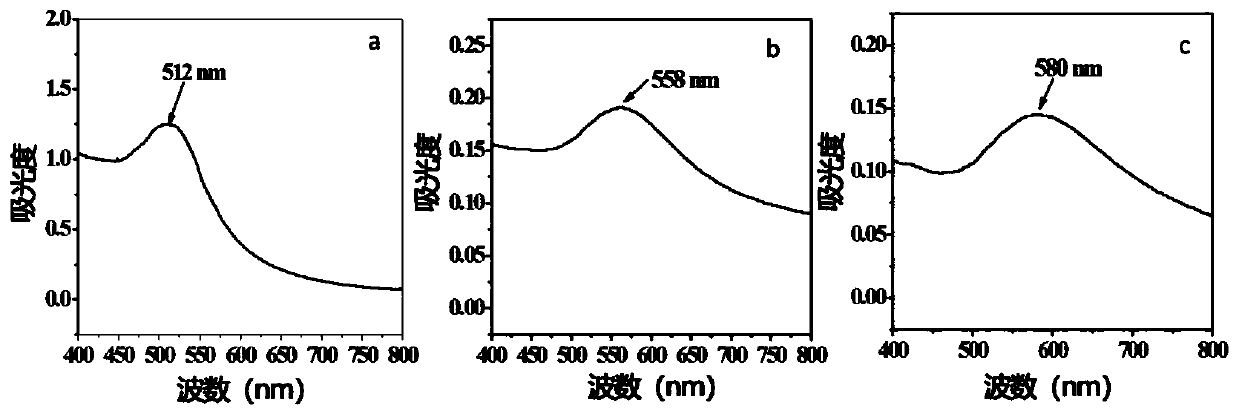

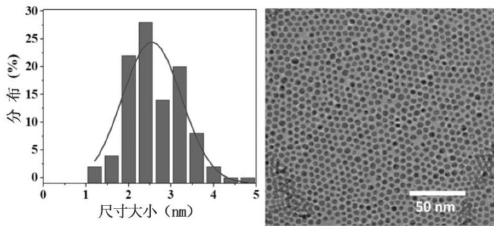

[0034] (1) Preparation of nano-gold solution: add 10 mL of deionized water to a 50 mL volumetric flask, shake, then add 50 μL of tetrachloroauric acid solution with a concentration of 50 mmol / L and 200 μL of sodium borohydride solution with a concentration of 50 mmol / L, and shake , in a water bath for 5 minutes, add 10 g of acetone and shake well, then add 10 g of n-hexane and 0.1 μL of dodecanethiol, and let stand to react for 30 minutes.

[0035] (2) Self-assembly and thermal annealing of the gold nanoarray array: 100 μL of toluene was added dropwise on the Teflon tape, and the gold nanometer array solution mixed with toluene was uniformly dispersed on the droplet. After the hexane-toluene solution was evaporated in the atmosphere, an orderly and regularly stacked gold nano-array appeared. Nano-gold serial vacuum oven heating for 3 hours (70Pa pressure 80 ℃), cooling at room temperature.

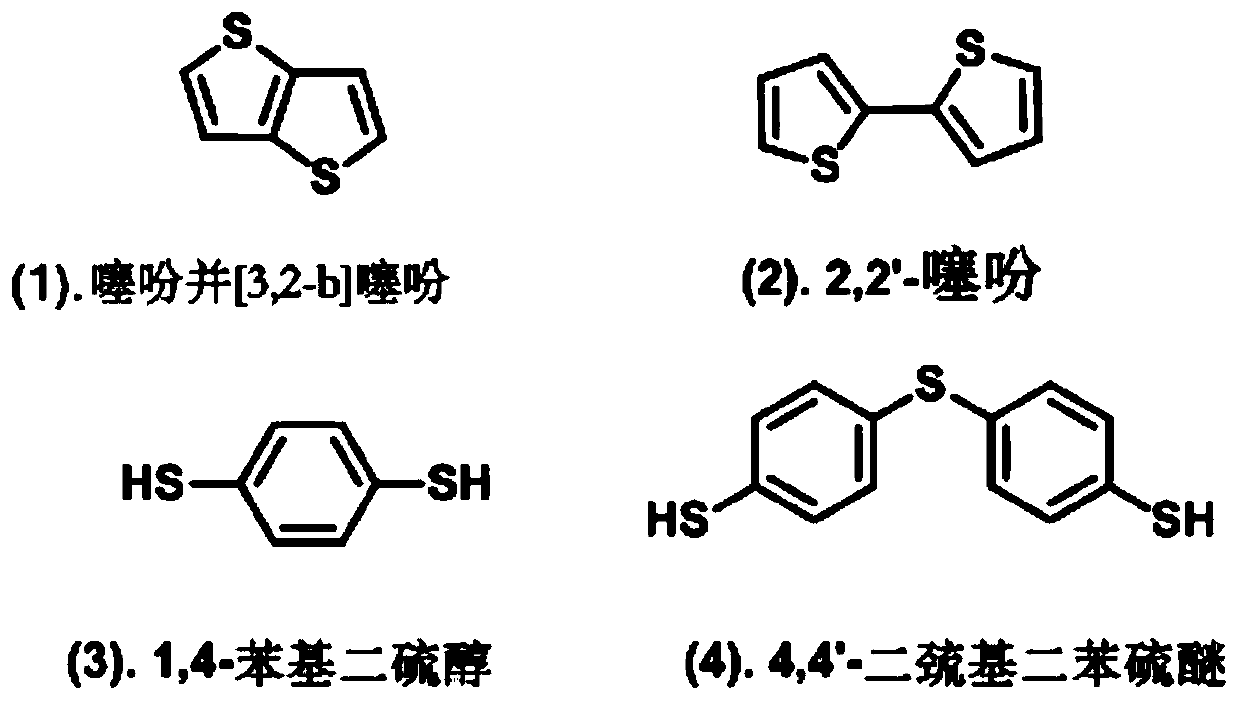

[0036] (3) Reaction of nano-gold arrays with rigid cross-linking agent: Nitrogen gas ...

Embodiment 2

[0039] (1) Preparation of nano-gold solution: add 10 mL of deionized water to a 50 mL volumetric flask, shake, then add 50 μL of tetrachloroauric acid solution with a concentration of 50 mmol / L and 200 μL of sodium borohydride solution with a concentration of 50 mmol / L, and shake , water bath for 5 minutes, add 1 g of acetone and shake well, then add 1 g of n-hexane and 0.01 μL of dodecanethiol, and let stand for reaction for 30 minutes.

[0040] (2) Self-assembly and thermal annealing of the gold nanoarray array: 100 μL of toluene was added dropwise on the Teflon tape, and the gold nanometer array solution mixed with toluene was uniformly dispersed on the droplet. After the hexane-toluene solution was evaporated in the atmosphere, an orderly and regularly stacked gold nano-array appeared. Nano-gold serial vacuum oven heating for 3 hours (70Pa pressure 80 ℃), cooling at room temperature.

[0041] (3) Reaction of nano-gold arrays with rigid cross-linking agent: Nitrogen gas was ...

Embodiment 3

[0044] (1) Preparation of nano-gold solution: add 10 mL of deionized water to a 50 mL volumetric flask, shake, then add 50 μL of tetrachloroauric acid solution with a concentration of 50 mmol / L and 200 μL of sodium borohydride solution with a concentration of 50 mmol / L, and shake , in a water bath for 5 minutes, add 100 g of acetone and shake well, then add 100 g of n-hexane and 1 μL of dodecanethiol, and let stand to react for 30 minutes.

[0045] (2) Self-assembly and thermal annealing of the gold nanoarray array: 100 μL of toluene was added dropwise on the Teflon tape, and the gold nanometer array solution mixed with toluene was uniformly dispersed on the droplet. After the hexane-toluene solution was evaporated in the atmosphere, an orderly and regularly stacked gold nano-array appeared. Nano-gold serial vacuum oven heating for 3 hours (70Pa pressure 80 ℃), cooling at room temperature.

[0046] (3) Reaction of the nano-gold array with the rigid cross-linking agent: Nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com