Practical training device for automatic control of medicine addition of multi-process floatation column separation system

A sorting system and training device technology, used in flotation, solid separation, instruments, etc., can solve the problems of typicality, poor applicability, poor portability, high labor intensity for flotation reagent addition, and different control levels, etc. problem, to reduce the lack of manual judgment experience, save manpower and material resources, and achieve the effect of wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

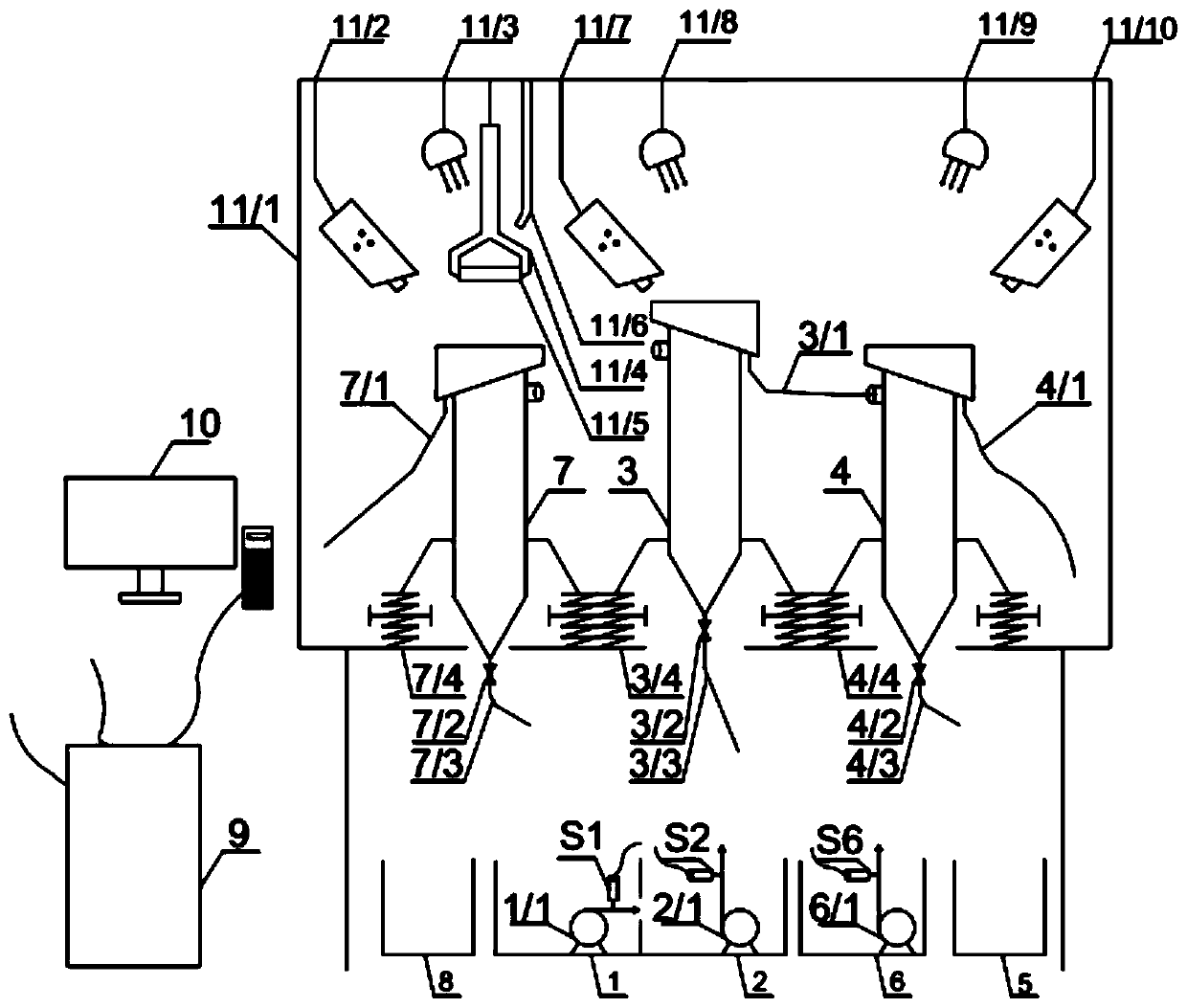

Embodiment 1

[0035] Taking the separation process of a single flotation column as an example, the countercurrent flotation column is selected, the foam product pipeline of the first flotation column is connected to the concentrate pool, the tailings of the first flotation column are connected to the tailings pool, and the chemical box The chemical is fed into the mixing tank by the dosing pump, the slurry in the mixing tank is fed into the first flotation column by the feeding pump, the foam product enters the concentrate tank, the tailings product enters the tailing tank, and the first flow sensor detects the flow value of the reagent , the second flow sensor and the third flow sensor detect the pulp flow value in the flotation system and input it into the expert control system, the first flotation column CCD camera takes the image of the foam layer and sends it to the expert control system to extract key information, the mechanical arm, sieve and flushing water pipe Located above the firs...

Embodiment 2

[0037] Taking a rough-fine-sweep separation process consisting of three flotation columns as an example, a countercurrent flotation column is selected, and a rough-fine-sweep process is selected through computer configuration software, and the foam product of the first flotation column is Feed into the second flotation column, the tailings of the first flotation column are fed into the second flotation column by the feed pump of the transfer tank, the foam product of the second flotation column is the final concentrate and enters the concentrate pool, the second The tailings of the flotation column return to the mixing tank, the foam product of the third flotation column flows into the mixing tank, the tailings product of the third flotation column is the final tailings and enters the tailings pond, the first flow sensor detects the flow value of the agent, The second flow sensor and the third flow sensor detect the pulp flow value in the flotation system and input it into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com