Ammonia-adsorption-based improved SBR biological nitrogen and phosphorus removal system and method for low-carbon-source sewage

A technology for biological denitrification and sewage, applied in water pollutants, water/sewage treatment, biological sludge treatment, etc., can solve the problem of low total nitrogen removal rate, achieve high phosphorus removal rate, save dosing, aeration The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

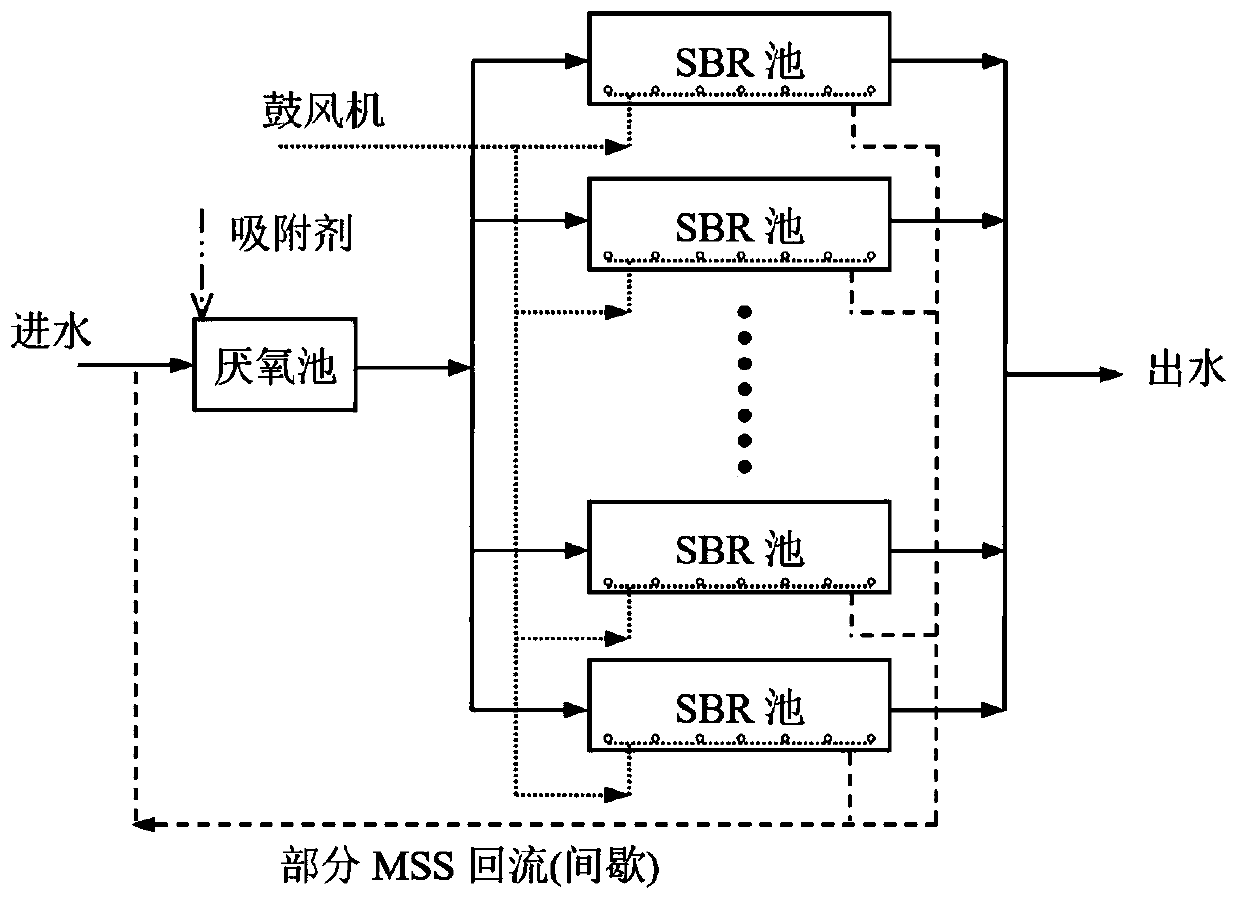

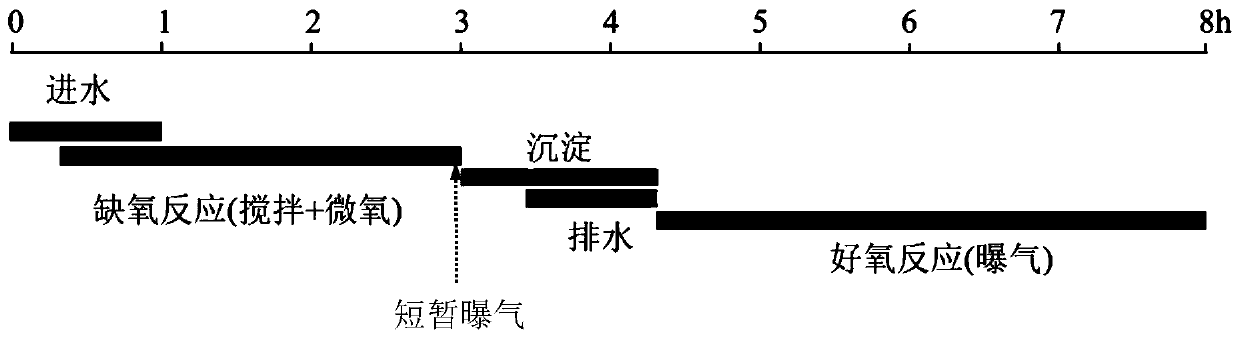

[0034] This embodiment provides an improved SBR biological denitrification and phosphorus removal system for low-carbon source sewage based on ammonia nitrogen adsorption, including: setting one anaerobic tank, and several SBR reaction tanks (usually 6 or 8), of which the anaerobic The tank adopts a mechanical flow device as a stirring measure. When the SBR reaction tank is in an aerated state, aeration is directly used as a stirring measure. When the SBR reaction tank is in an anoxic state, it needs to maintain stirring, and a mechanical flow device is used as a stirring measure when anoxic. .

[0035] Add powdered adsorbent (modified ultrafine quartz sand powder or modified river sand can be used) to the system, and directly sprinkle the powdered adsorbent into the anaerobic pool or SBR pool. Ammonia nitrogen is adsorbed by the joint action of sludge and adsorbent.

[0036] In order for the sludge to obtain a high adsorption effect of ammonia nitrogen, it is necessary to ma...

Embodiment 2

[0047] This embodiment provides an improved SBR process that approximates this method with a beaker experiment.

[0048] Take 10L of sludge from an anaerobic tank of an urban sewage plant, 0.10g of ferric chloride (adding iron salt solution, non-directly adding solids, the same below) and stir for 2h in a closed environment, then settle for 1h. The municipal sewage plant process for the sludge collected is Carrousel 2000 oxidation ditch, with an anaerobic tank in front, and the sludge is returned to the anaerobic tank. Get the supernatant after precipitation as anaerobic sewage, measure its ammonia nitrogen concentration as 15.3mg / L, total nitrogen concentration 17.1mg / L (original sewage total nitrogen 37.7mg / L), COD Cr The concentration is 101mg / L, BOD 5 is 49mg / L, the carbon-to-nitrogen ratio of the sewage is too low, adding a certain amount of glucose makes its theoretical BOD 5 Reach 55mg / L, that is, the theoretical carbon-nitrogen ratio reaches 3.0. Since the sewage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com