Concrete for building wall construction and preparation method of concrete

A concrete and building technology, which is applied in the field of concrete for building wall construction and its preparation, can solve problems such as performance degradation, and achieve the effects of low production cost, light weight, and good product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

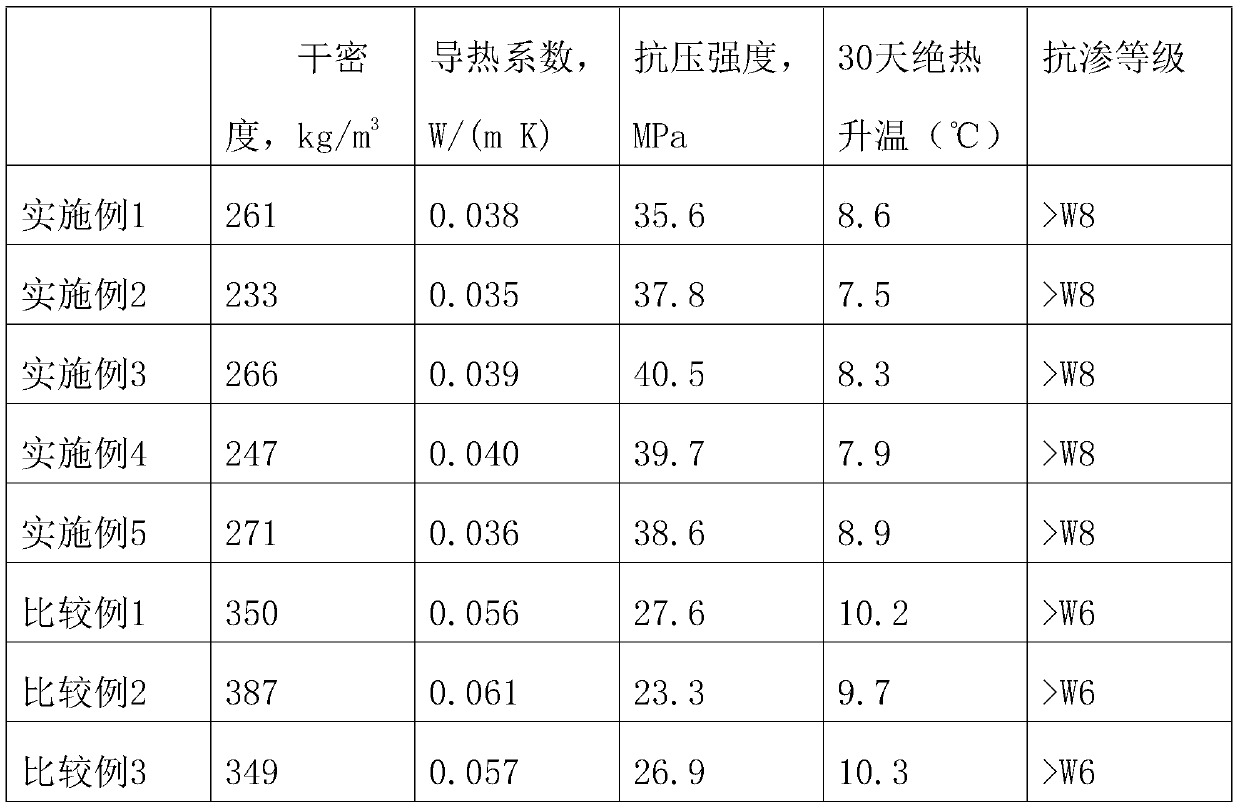

Examples

preparation example Construction

[0036] In the present invention, airgel, composite fiber, lightweight filler and foaming agent are the core components of the present invention, which are essential components to make it optimally applicable to building walls: airgel has thermal insulation properties and can Eliminate heat exchange between indoor and outdoor environments, and achieve the effect of warming in winter and cooling in summer; the composite fiber is preferably selected from one or more of stainless steel fiber, polypropylene resin fiber and hydroxyethyl fiber, and the composite fiber can be combined with concrete Form an interwoven network structure between them to improve the structural strength of concrete; lightweight fillers and foaming agents are used to reduce the density of concrete, increase the seismic performance of concrete walls, and reduce transportation costs. The foaming agent can be selected from any existing The foaming agent and the light filler include the following ingredients in ...

Embodiment 1

[0049] A concrete for building wall construction, comprising: 33 parts of cement, 1 part of ethylene glycol monobutyl ether, 1.5 parts of silicone oil, 42 parts of mixed gravel, 14 parts of coarse sand, 35 parts of fine sand, 15 parts of ceramic waste, waste 15 parts of concrete, 15 parts of fine aggregate, 15 parts of airgel, 18 parts of composite fiber, 12 parts of lightweight filler, 12 parts of foaming agent and 20 parts of admixture.

[0050] Among them, the additives include: 18 parts of polycarboxylate water reducer, 13 parts of hardener, 5 parts of cellulose grafted chitosan, 8 parts of silane coupling agent, 8 parts of silicon carbide, 8 parts of vitrified microbeads, 12 parts of gelatin powder, 5 parts of anhydrous sodium sulfite, 5 parts of sodium hexametaphosphate, 15 parts of seaweed powder and 15 parts of activator.

[0051] The polycarboxylate water reducer includes: 15 parts of methacrylic acid, 15 parts of carbon fiber, 15 parts of sodium tetraborate, 10 parts...

Embodiment 2

[0055] A concrete for building wall construction, comprising: 30 parts of cement, 2 parts of ethylene glycol monobutyl ether, 1 part of silicone oil, 40 parts of mixed gravel, 15 parts of coarse sand, 35 parts of fine sand, 10 parts of ceramic waste, waste 10 parts of concrete, 10 parts of fine aggregate, 10 parts of airgel, 20 parts of composite fiber, 15 parts of lightweight filler, 10 parts of foaming agent and 18 parts of admixture.

[0056] Among them, the additives include: 16 parts of polycarboxylate water reducer, 14 parts of hardener, 7 parts of cellulose grafted chitosan, 7 parts of silane coupling agent, 7 parts of silicon carbide, 7 parts of vitrified microbeads, 10 parts of gelatin powder, 6 parts of anhydrous sodium sulfite, 6 parts of sodium hexametaphosphate, 10 parts of seaweed powder and 10 parts of activator.

[0057] The polycarboxylate water reducer includes: 20 parts of methacrylic acid, 20 parts of carbon fiber, 15 parts of sodium tetraborate, 10 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com