Preparation process of novel tower granulation compound fertilizer

A high-tower granulation and preparation technology, applied in the direction of phosphate fertilizer, fertilization device, fertilizer mixture, etc., can solve the problem of low utilization rate of compound fertilizer, achieve the effects of saving drying energy consumption, not easy to agglomerate, and improving the slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

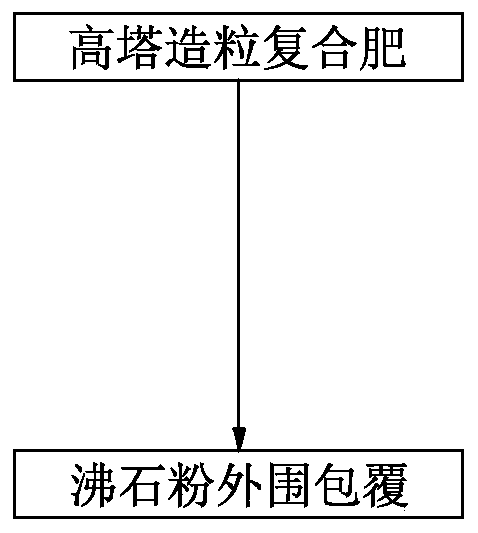

[0028] Such as figure 1 As shown, the preparation process of a novel high-tower granulated compound fertilizer involved in the present invention includes the steps of high-tower granulated compound fertilizer and the step of using zeolite powder for outer coating. In this way, the present invention can form a layer of zeolite powder on the periphery of the conventional high-tower granulated compound fertilizer due to the addition of the step of zeolite powder coating on the periphery, which can improve the slow-release effect of the compound fertilizer to a certain extent.

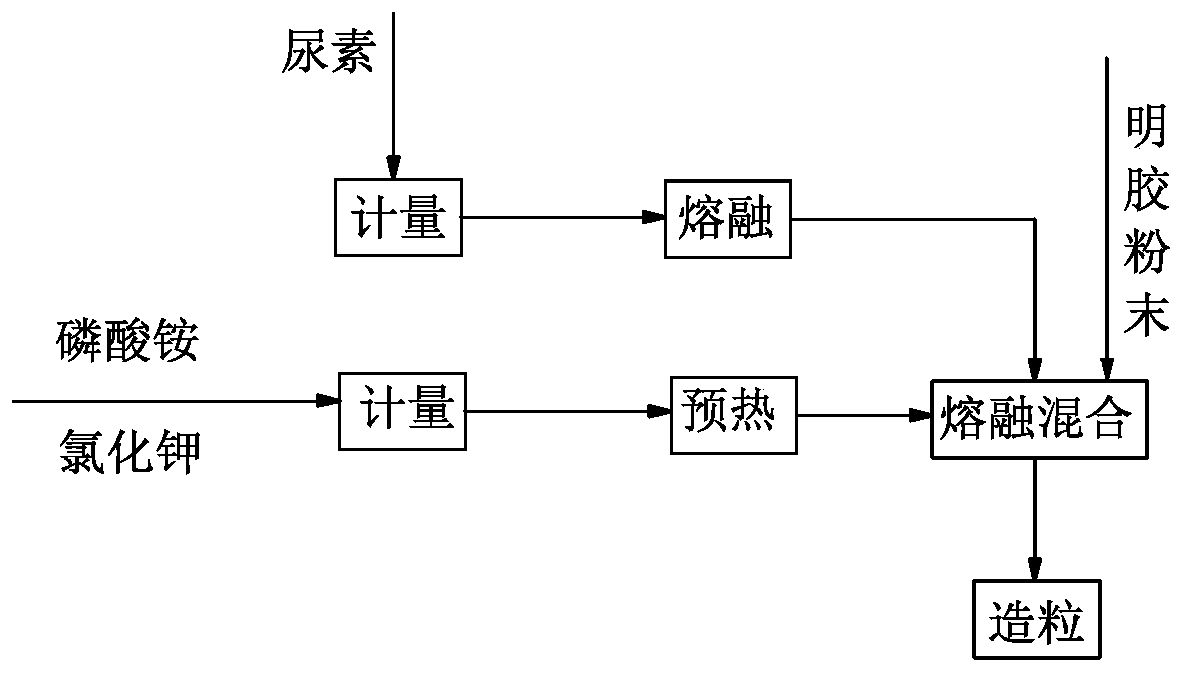

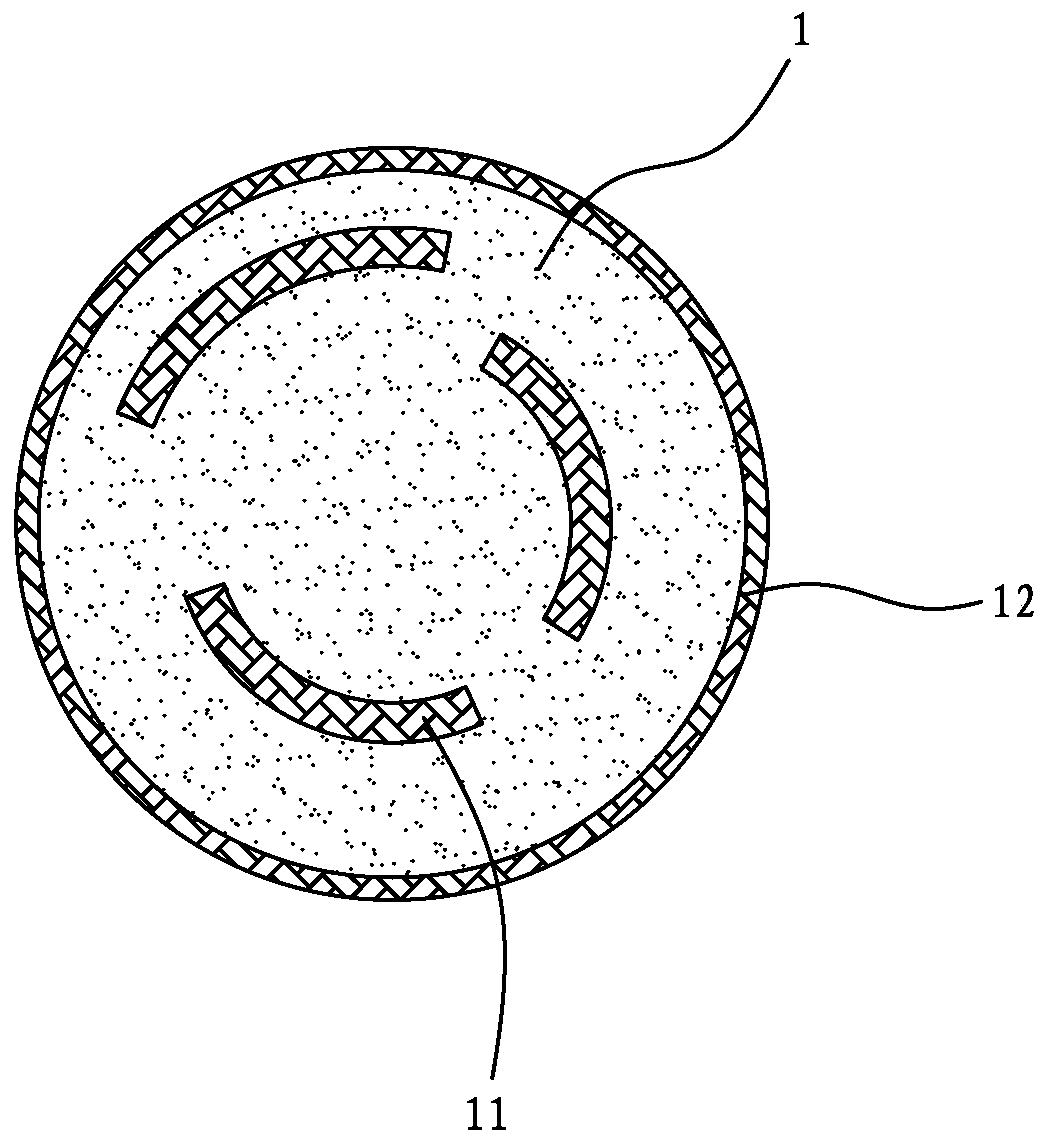

[0029] In addition, in the process of high-tower granulation compound fertilizer, it forms a mixed and molten state of urea, ammonium phosphate and potassium chloride in the mixing tank, and then extrudes the granules with several spaced ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com