Anionized 2-hydroxypropyltrimethylammonium chloride chitosan and its preparation method and application

A hydroxypropyl trimethyl ammonium chloride, anionization technology, applied in the application, cosmetic preparations, cosmetics and other directions, can solve the problem of insufficient support for development and utilization, and achieves good moisture absorption and moisturizing activity, low material cost, and high productivity. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

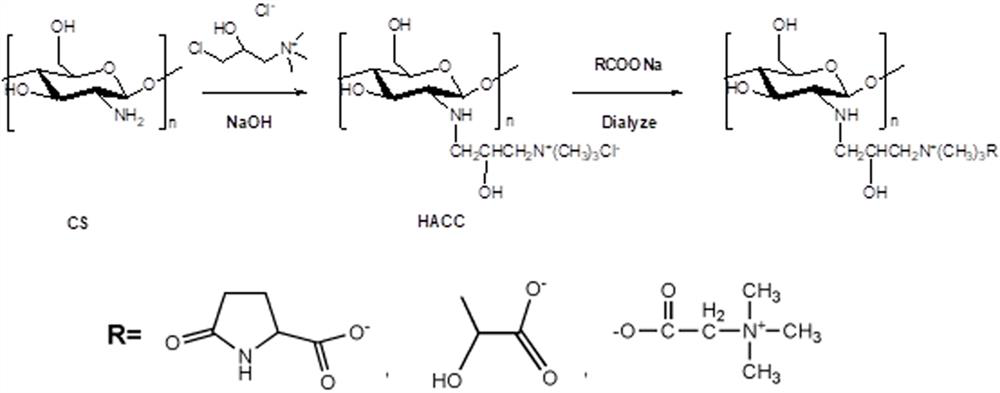

[0036] Such as figure 1 The synthesis route of anionized 2-hydroxypropyltrimethylammonium chloride chitosan shown, wherein n represents the degree of polymerization, and the average value range is 50-1000.

[0037] (1) Weigh 3.38g of chitosan (molecular weight about 50,000) and disperse it in 30mL of isopropanol for swelling, add dropwise 1.2mL of 40% sodium hydroxide aqueous solution and 60% of 3-chloro - 19 mL of 2-hydroxypropyltrimethylammonium chloride solution, reacted in a metal bath reaction pot at 55°C for 9 hours, precipitated and washed with ethanol after the reaction, filtered with suction and dried to obtain 2-hydroxypropyltrimethylammonium chloride trimethylammonium chloride chitosan.

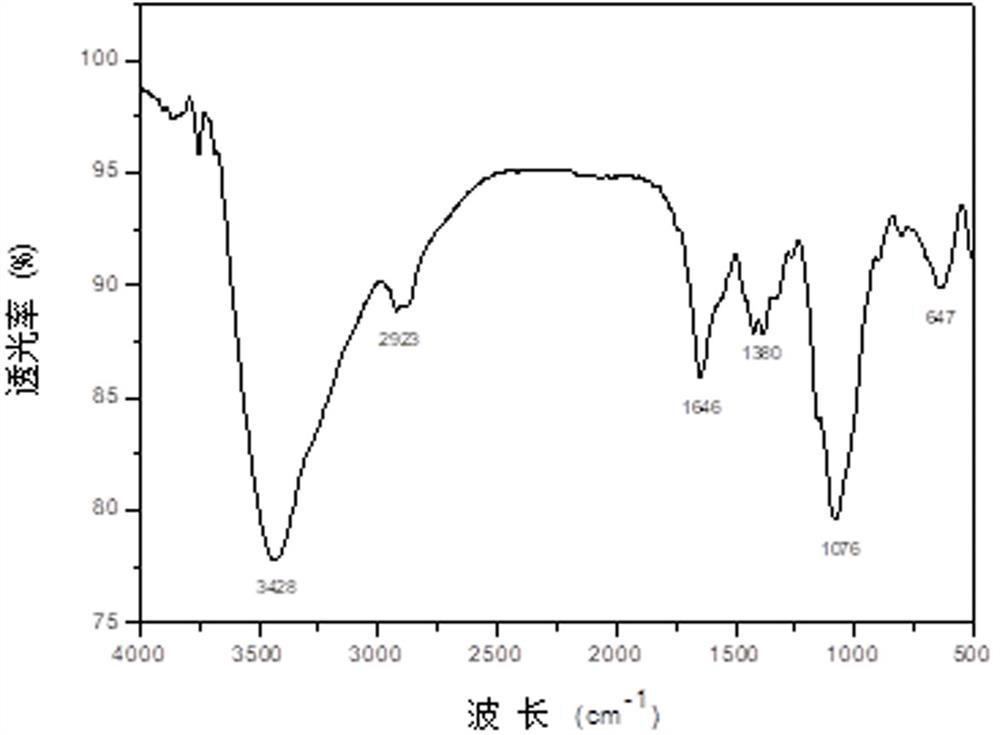

[0038] (2) Weigh 3 g of the above-mentioned 2-hydroxypropyltrimethylammonium chloride chitosan and dissolve it in 60 mL of deionized water, and then add 30 mL of an aqueous solution of sodium pyrrolidone carboxylate with a mass fraction of 15% to the former, at room temperature R...

Embodiment 2

[0040] The difference from Example 1 is:

[0041] (1) Weigh 3.38g of chitosan (molecular weight about 100,000) and disperse it in 25mL of isopropanol for swelling, add dropwise 1.4mL of sodium hydroxide aqueous solution with a mass fraction of 40%, and 60% of 3-chloro - 25 mL of 2-hydroxypropyltrimethylammonium chloride solution, reacted in a metal bath at 60°C for 10 hours, precipitated and washed with ethanol after the reaction, filtered with suction and dried to obtain 2-hydroxypropyltrimethylammonium chloride Methylammonium Chloride Chitosan.

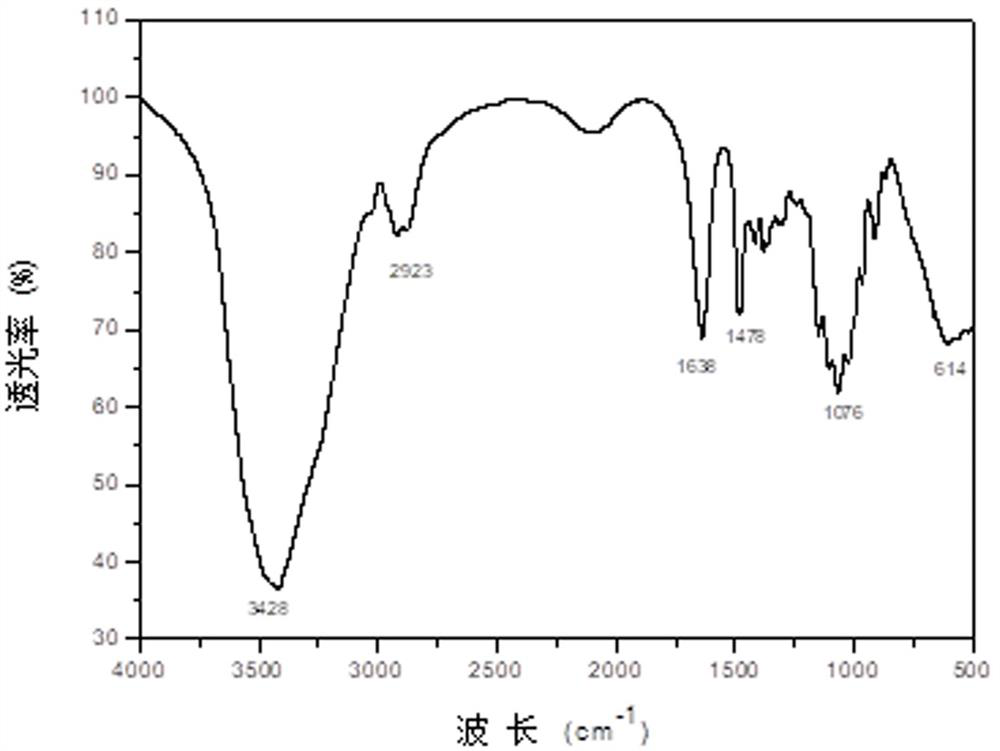

[0042] (2) Weigh 3 g of 2-hydroxypropyltrimethylammonium chloride chitosan and fully dissolve it in 30 mL of deionized water, transfer it to a dialysis bag with a molecular weight cut-off of 500, and dialyze it in a 10% sodium lactate aqueous solution After 12 hours, dialyze with deionized water for 24 hours after the reaction, concentrate and freeze-dry to obtain sodium lactate anionized 2-hydroxypropyltrimethylammonium chloride chi...

Embodiment 3

[0044] The difference from Example 1 is:

[0045] (1) Weigh 3.38g of chitosan (molecular weight about 150,000) and disperse it in 15mL of isopropanol for swelling, add dropwise 1.6mL of 40% sodium hydroxide aqueous solution and 60% of 3-chloro - 30mL of 2-hydroxypropyltrimethylammonium chloride solution, reacted in a metal bath at 75°C for 12 hours, precipitated and washed with ethanol after the reaction, filtered with suction and dried to obtain 2-hydroxypropyltrimethylammonium chloride Methylammonium Chloride Chitosan.

[0046] (2) Weigh 3 g of the above-mentioned 2-hydroxypropyltrimethylammonium chloride chitosan, dissolve it in 20 mL of deionized water, transfer it to a dialysis bag with a molecular weight cut-off of 500, and perform a dialysis reaction in a betaine aqueous solution with a concentration of 15%. After 12 hours, dialyze with deionized water for 48 hours after the reaction, concentrate and freeze-dry to obtain betaine anionized 2-hydroxypropyltrimethylammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com