Thick-film high-temperature resistant coating capable of self-drying at normal temperature, and preparation method and application thereof

A high-temperature-resistant coating and high-temperature-resistant pigment technology, applied in the direction of anti-corrosion coatings, fire-resistant coatings, coatings, etc., can solve the problem of no breakthrough in high film thickness performance, single technical index heat resistance, high film thickness and color changes are not mentioned and other problems, to achieve the effect of being convenient for large-scale use, good corrosion and protection performance, and no need to bake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

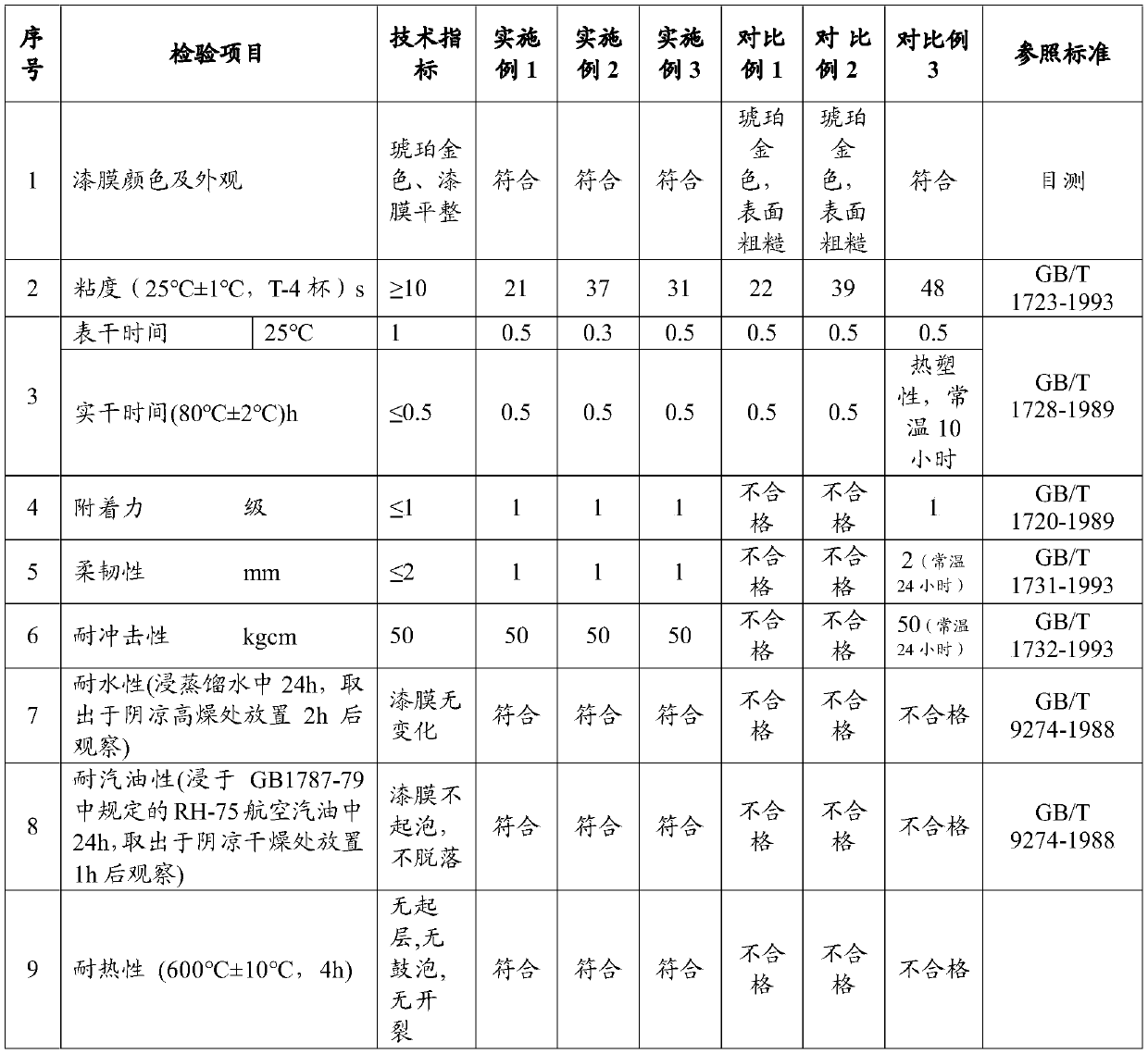

Examples

preparation example Construction

[0028] Another aspect of the embodiment of the present invention provides a method for preparing the aforementioned normal temperature self-drying thick-film high-temperature-resistant coating, which includes: modifying silicone resin, golden high-temperature-resistant pigment, flaky low-hiding filler, butanol, The grafted coupling agent and alignment agent are mixed and stirred evenly, and then the viscosity of the obtained mixture is adjusted with xylene, so as to obtain the normal temperature self-drying thick-film high-temperature-resistant coating.

[0029] Further, the stirring time is 20-30 min, and the rotation speed is 2000-4000 r / min.

[0030] Further, the viscosity of the obtained mixture was adjusted to Tu-4 cup for 10-50 seconds with xylene.

[0031] Another aspect of the embodiments of the present invention provides a normal-temperature self-drying thick-film high-temperature resistant coating, which is formed from the aforementioned normal-temperature self-dryin...

Embodiment 1

[0047] According to mass percentage (if not specified below, it refers to the mass percentage content of each component in the normal temperature self-drying thick film high temperature resistant coating) respectively take 41% of Rhodia 6407 modified silicone resin, KH560 silane coupling agent Add 2%, butanol 2%, xylene 10% into the mixing pot and stir for 5 minutes at a speed of 4000r / min. While stirring, continue to add 15% of HC9305 pearl powder, 15% of GA-2 wet-process sericite powder, and HC305 pearl powder Powder 5%, KJ-9200SA aligning agent 1.3%, continue to stir at the same speed for 10 minutes, adjust the viscosity to T-4 cup 20-40S with xylene, filter to obtain the normal temperature self-drying thick film high temperature resistant coating.

Embodiment 2

[0049] According to mass percentage (if not specified below, it refers to the mass percentage content of each component in the normal temperature self-drying thick film high temperature resistant coating), respectively take FJN-9801 modified silicone resin 60%, KBM-403 silane Add 0.3% of coupling agent, 3.2% of butanol, and 10% of xylene into the mixing pot and stir for 5 minutes at a speed of 3000r / min. While stirring, continue to add 14% of HC9305 pearl powder and 3% of GA-2 wet-process sericite powder , 800 mesh glass flakes 3%, SG-205 aligning agent 0.5%, continue to stir at the same speed for 15 minutes, adjust the viscosity to T-4 cup 20-40S with xylene, and filter to obtain the normal temperature self-drying thick film High temperature resistant coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com