Spraying tower, exhaust system and boiler system

A technology of spray tower and spray layer, applied in the field of flue gas purification devices, can solve the problems of limited cooling range of wet flue gas, excessive consumption of cooling slurry, large heat exchange area, etc. Thermal effect, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

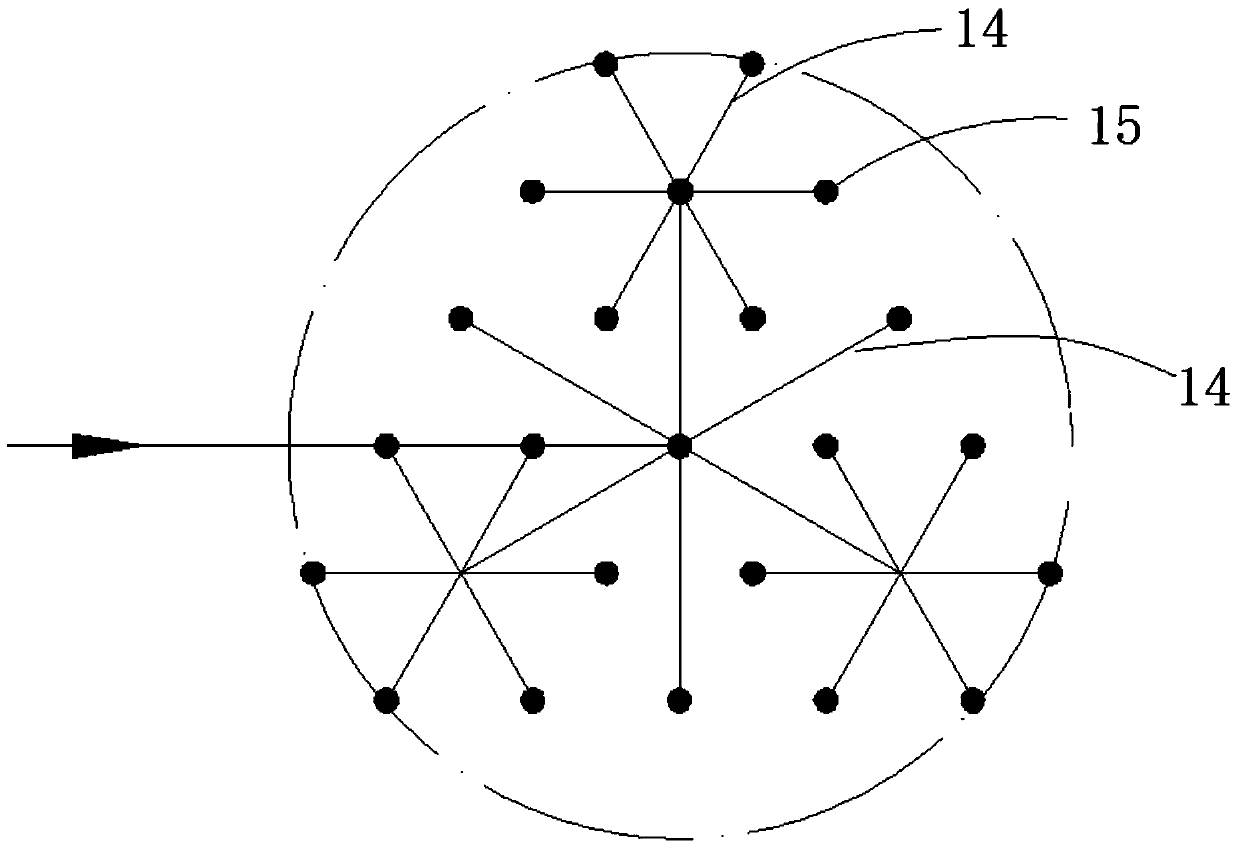

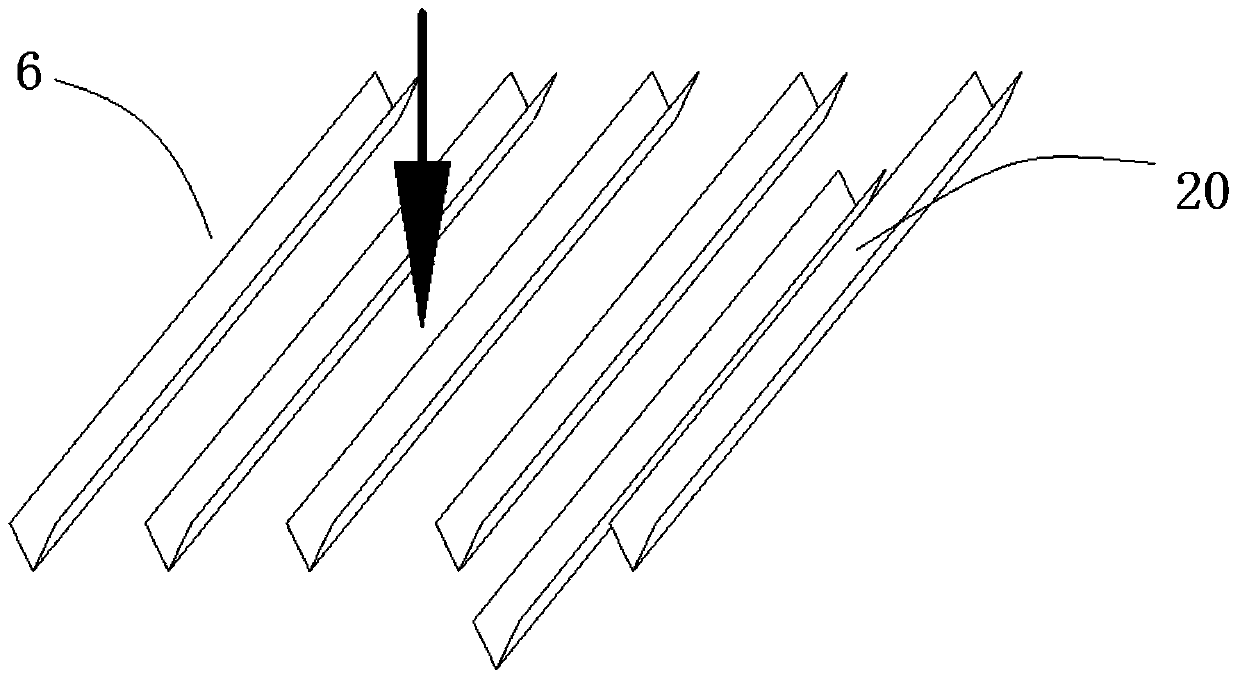

[0032] The spray tower 27 of this embodiment is a wet flue gas spray tower with direct contact between cold and hot zones, which can reduce the temperature of the flue gas and dissolve impurities in the flue gas, such as figure 1 As shown in -4, the spray tower 27 includes a tower body 1, a first group of spray layers 2, a second group of spray layers 3, a first liquid storage tank 4, a second liquid storage tank 5, a turbulent liquid holder 6, The first circulation assembly 7, the second circulation assembly 8 and the cooling assembly.

[0033] In this embodiment, the material of the tower body is Q235 steel plate with a wall thickness of 5 mm, the inner wall of the tower body 1 must undergo anti-corrosion treatment, and the thickness of the anti-corrosion glass flakes is not less than 3 mm.

[0034] The tower body 1 is provided with a first group of spray layers 2 and a second group of spray layers 3, and corresponding to the first group of spray layers 2 for collecting the ...

Embodiment 2

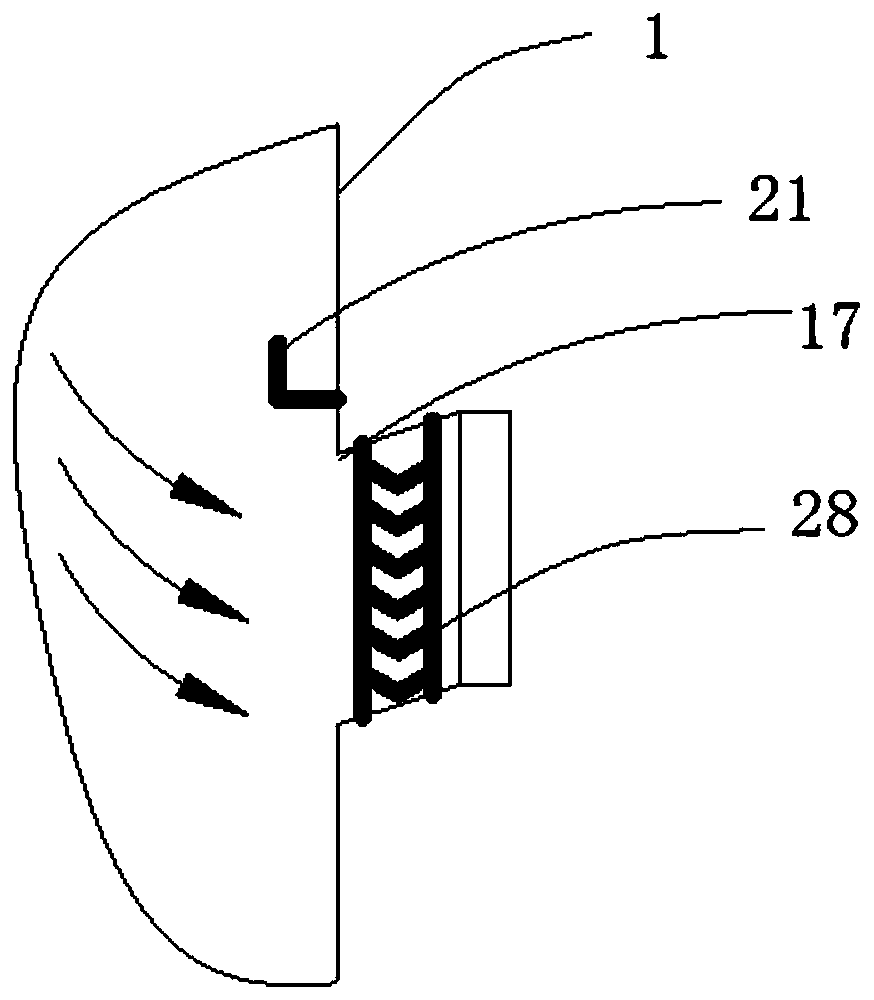

[0049] The exhaust system of this embodiment, such as Figure 5 As shown, it includes a deduster 25, a desulfurizer 26, a spray tower 27 described in Embodiment 1, and a chimney 29 connected in sequence. In order to reduce the humidity of the flue gas discharged, a mist eliminator 28 is set corresponding to the outlet flue 17 of the spray tower 27, and in order to facilitate the setting of the mist eliminator 28, in this embodiment, refer to figure 1 , the demister 28 is arranged on the outside of the spray tower 27 .

[0050] The exhaust system of this embodiment can be used in devices that require flue gas purification and flue gas whitening, such as coal-fired power generation, boiler 22, and the application range of the exhaust system is very wide.

[0051] When the exhaust system is used in the boiler system, it includes a boiler 22, a denitrification device 23, a low-temperature economizer 24, and the above-mentioned exhaust system connected in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com