Liquid level sensor by adopting optical fiber bundle and image processing technology

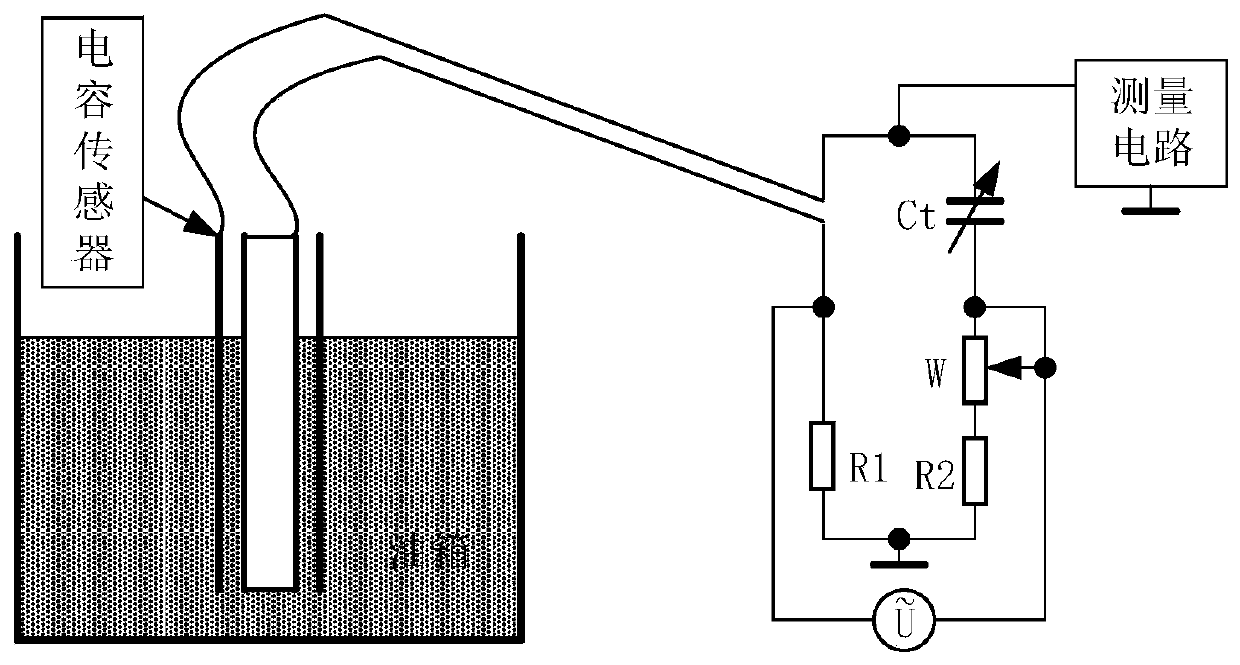

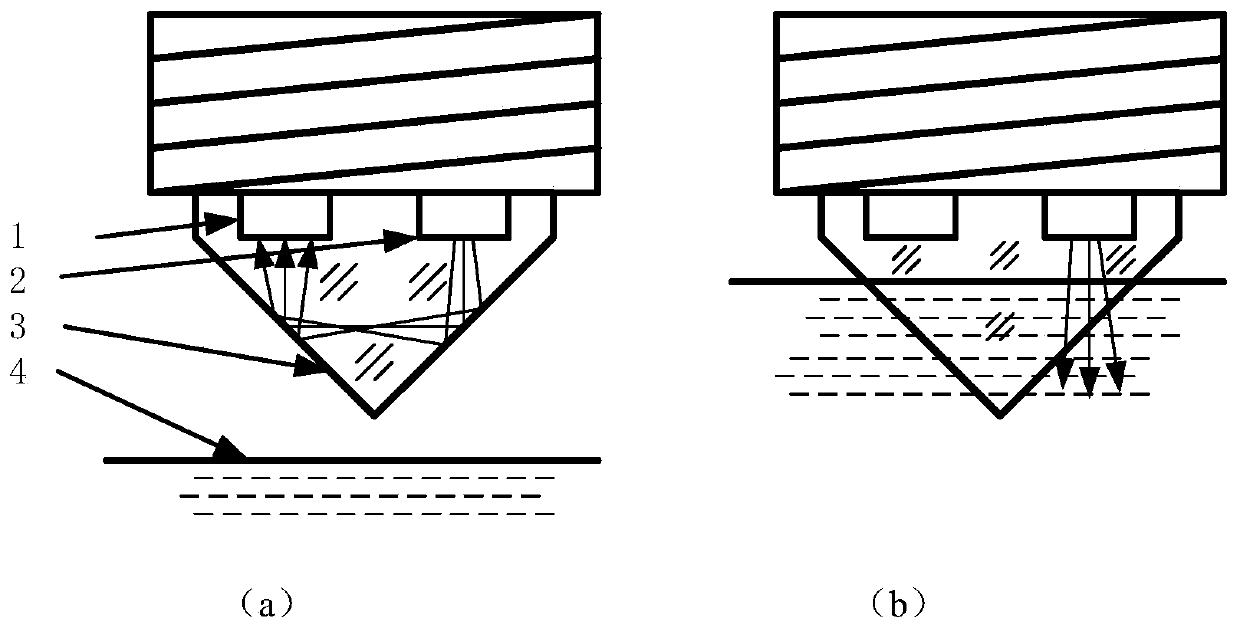

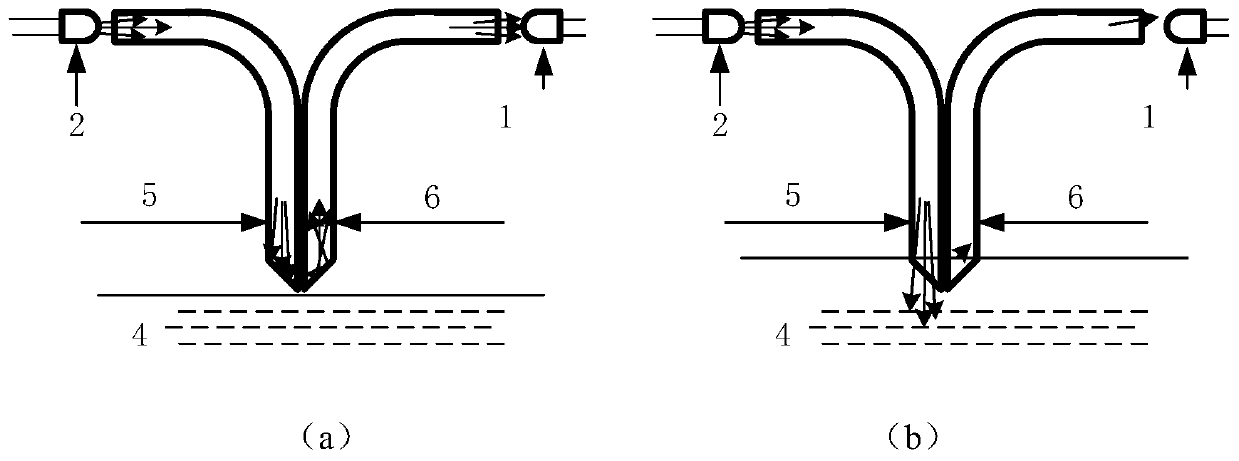

A liquid level sensor and image processing technology, applied in the field of liquid level sensors, can solve problems such as low precision, mechanical failure, and occupation of capacitive sensors, and achieve the effects of high calculation accuracy, small footprint, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Assume that the application conditions are that the maximum depth of the liquid is 1 meter, the measurement resolution is 1 mm, normal temperature and pressure, the wavelength of the light source is 650 nm, and the refractive index of the liquid to the light source is 1.5.

[0060] The number of probes required is 1000. There are 1000 sending and receiving optical fibers each. Arranged in a square matrix of 32X32 at the sending end and receiving end. Choose a plastic optical fiber with an outer diameter of 0.5mm. The section size of the fiber bundle at the illumination end and the image acquisition end is 16X16mm. The section of the detection section is arranged according to 64X32, and the section size is 32X16mm.

[0061] At present, the materials of plastic optical fiber include PS, PMMA, PC, fluoroplastic, etc., and the optical fiber can be selected according to the properties of the liquid.

[0062] Illumination source can choose 1W single red LED, 15 degree angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com