Novel tea juice concentration method

A tea juice, a new type of technology, applied in the field of tea juice concentration, can solve the problems of poor sensory quality, high production cost, turbidity and precipitation, etc., achieve the effect of less pollution on the membrane surface, reduce product loss, and improve cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

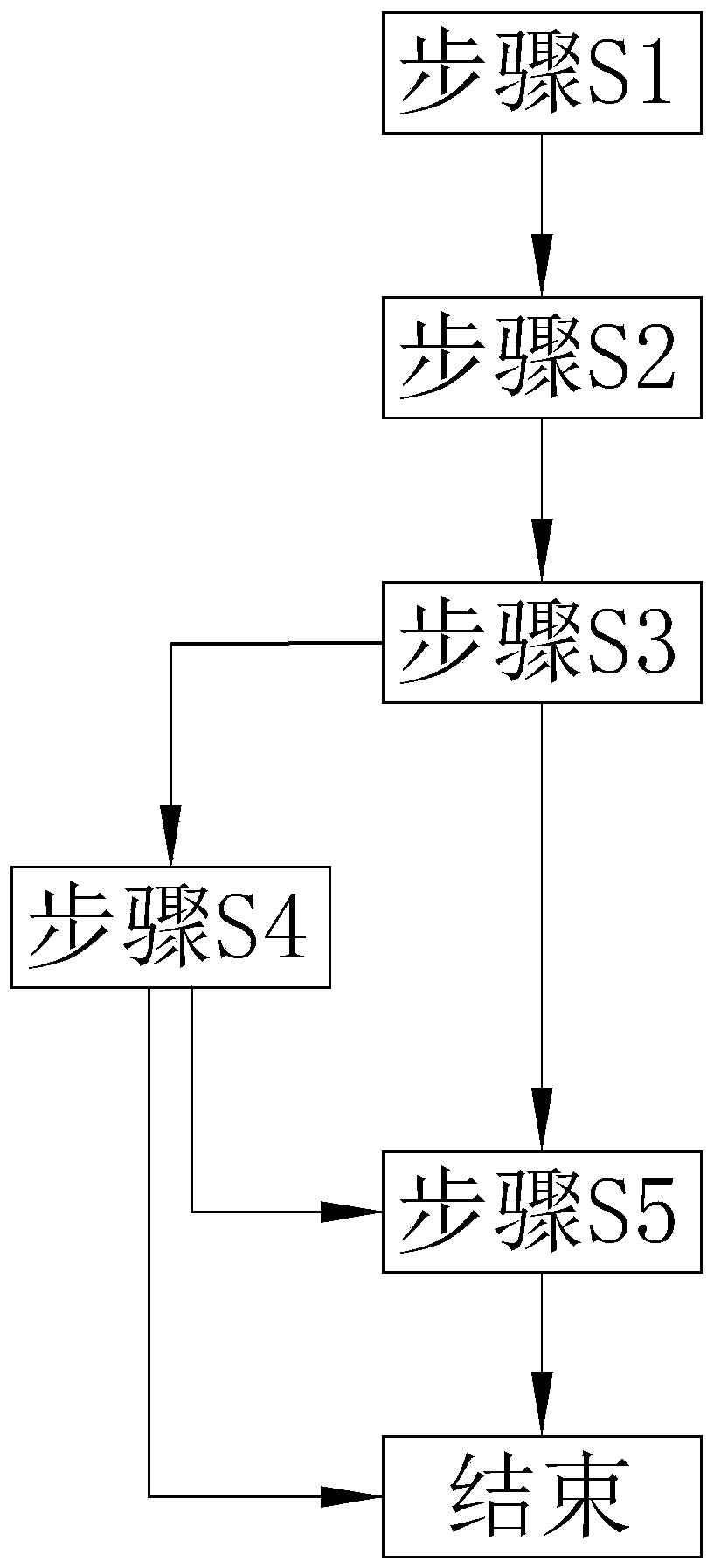

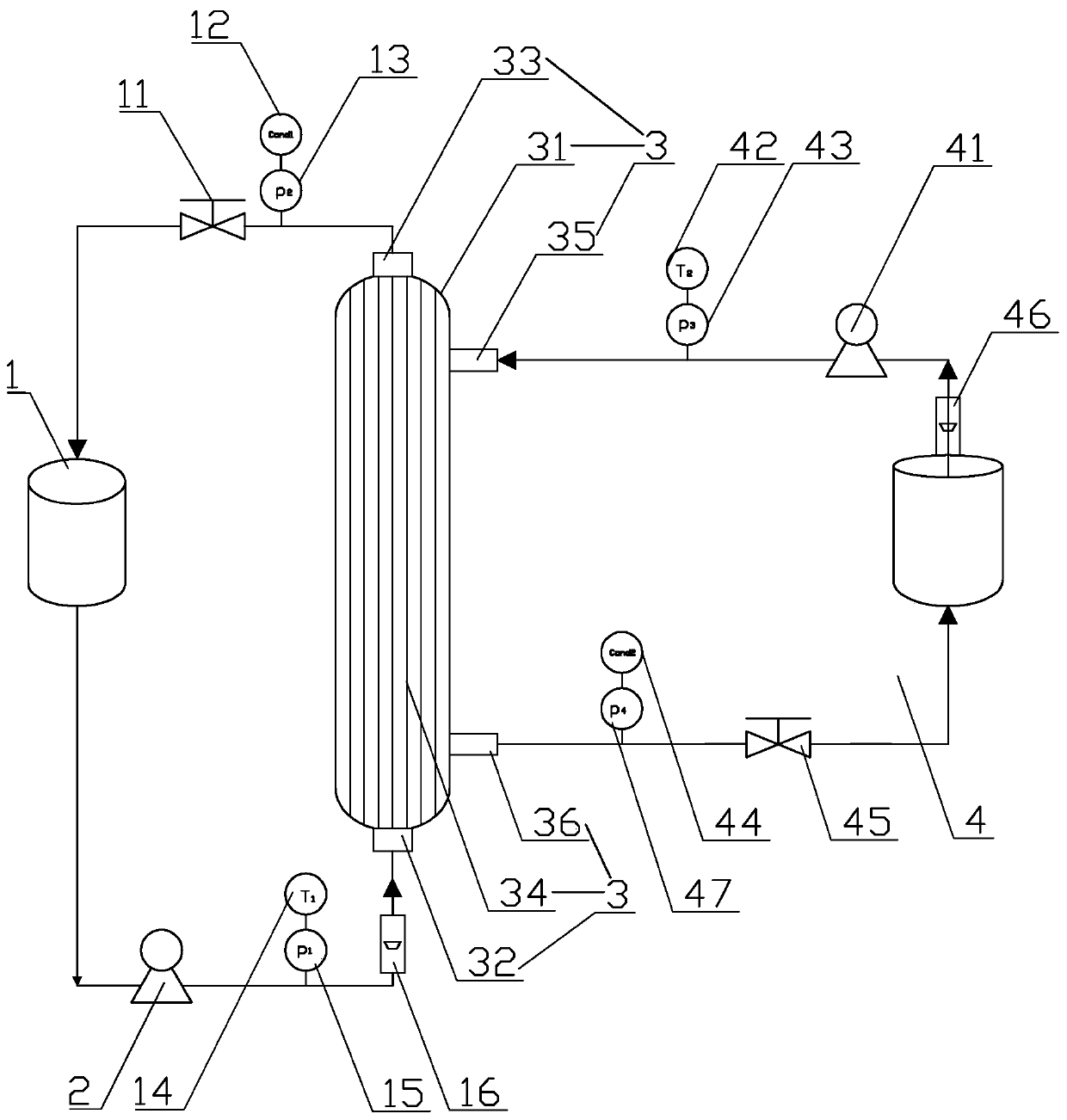

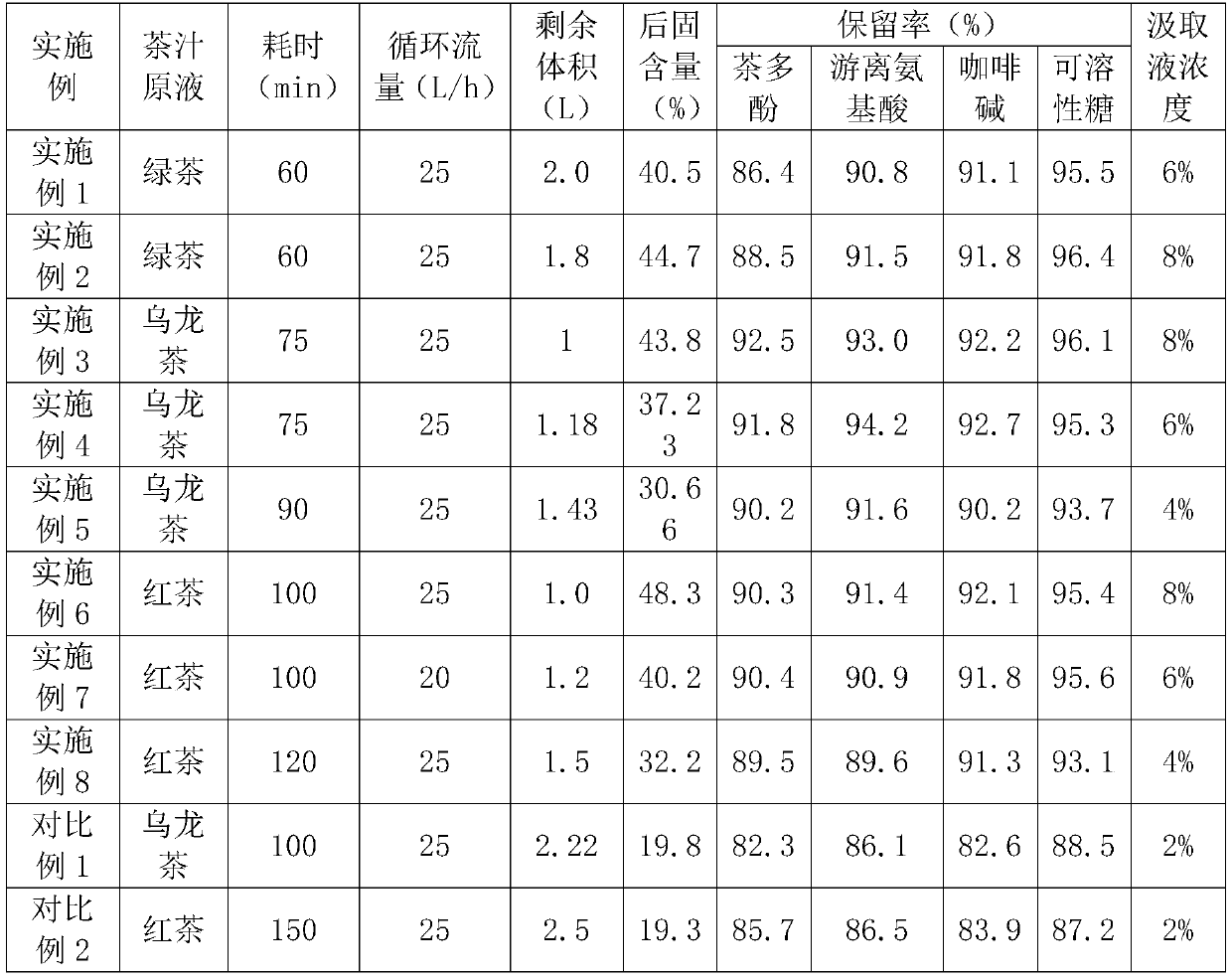

[0034] Embodiment 1: as figure 1 , figure 2 As shown, in the present embodiment, the tea juice stock solution is green tea juice. After the original green tea juice is filtered through a 300-mesh and 500-mesh filter or filter bag, the concentration of the original tea juice is 2.2%. Take a volume of 50 L and put it into the raw material tank 1. A 6% sodium chloride solution is used as the drawing liquid, and a volume of 10 L is put into the drawing liquid tank 4 . When concentrating, the system temperature is 25°C, the operating pressure is 1 bar, the circulating flow rate of the green tea stock solution is 25L / h, and the circulating flow rate of the drawing solution is 10L / h. After 60 minutes of operation, the remaining volume of the green tea juice solution is 2L. The concentrated green tea concentrated juice has a solid content of 40.5% brix, a retention rate of tea polyphenols of 86.4%, a retention rate of soluble sugar of 95.5%, a retention rate of caffeine of 91.1%, an...

Embodiment 2

[0035] 实施例2:本实施例与实施例1的区别在于,茶汁原液为绿茶汁,原绿茶汁经过300目和500目的滤网或滤袋过滤后,原茶汁浓度为2.2%,绿茶原液循环流量25L / h,汲取液为浓度为8%的氯化钠溶液。

Embodiment 3

[0036] 实施例3:本实施例与实施例1的区别在于,茶汁原液为乌龙茶汁,原乌龙茶汁经过300目和500目的滤网或滤袋过滤后,原茶汁浓度为0.9%,乌龙茶原液循环流量25L / h,汲取液为浓度为8%的氯化钠溶液。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com