Chinese wampee leaf and Chinese wampee fruit mixed fermented fruit wine and processing method thereof

A technology of mixed fermentation and processing method, which is applied in the direction of drug combination, pharmaceutical formula, preparation of alcoholic beverages, etc., to achieve the effect of expanding application, improving application value, good flavor and efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

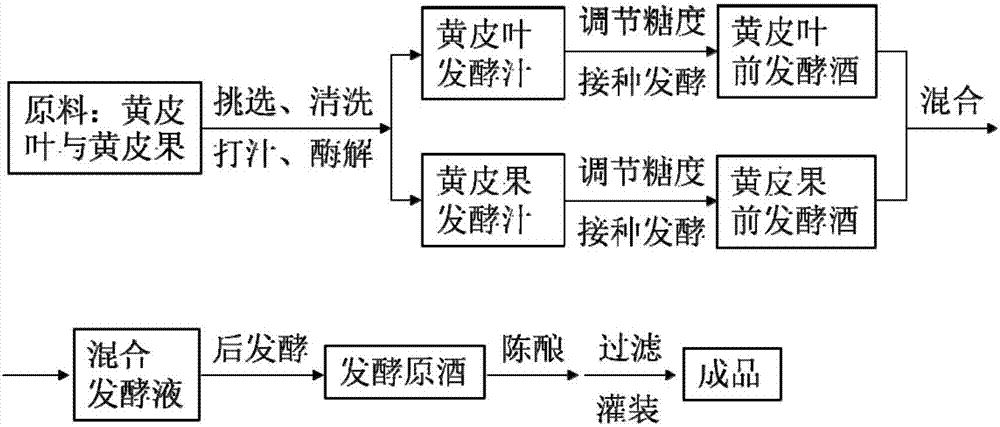

Method used

Image

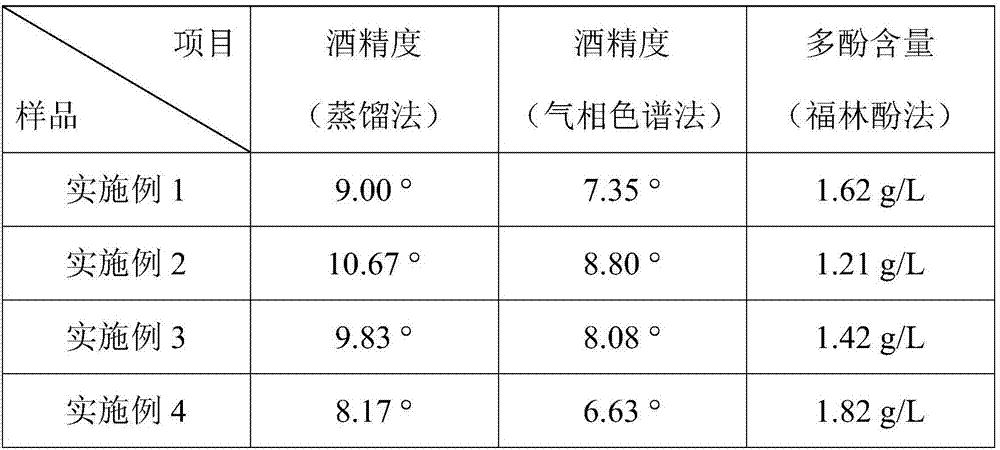

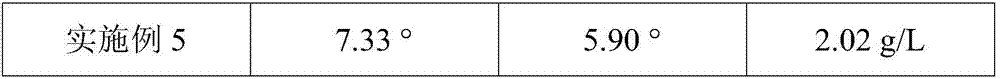

Examples

Embodiment 1

[0040] (1) Screening of yellow skin leaves and yellow skin fruits

[0041] Screen the mature and insect-free yellow-skin leaves and yellow-skinned fruits, wash them with clean water and set aside.

[0042] (2) Preparation of fermented juice:

[0043] Ⅰ. Preparation of wampee leaf juice: get 500 g of wampee leaves screened in step (1), add 9 times of water for beating; adjust cellulase concentration to 120ppm, adjust pectinase concentration to 60ppm, enzymolysis at 35°C After 3 hours, the yellow skin leaf juice is obtained;

[0044] Ⅱ. Preparation of wampee fruit juice: Take 2.5kg of wampee fruit screened in step (1), add water for beating according to the material-to-water ratio of 1:1 (mass, the same below), adjust the cellulase concentration to 300ppm, and adjust the pectin Enzyme concentration is 150ppm, enzymatic hydrolysis at 35°C for 3 hours to get wampeskin juice;

[0045] (3) Separate fermentation in the early stage:

[0046] 1. the pre-fermentation of the wampeski...

Embodiment 2

[0055] (1) Screening of yellow skin leaves and yellow skin fruits

[0056] Screen the mature and insect-free yellow-skin leaves and yellow-skinned fruits, wash them with clean water and set aside.

[0057] (2) Preparation of fermented juice:

[0058] Ⅰ. Preparation of wampee leaf juice: take 500 g of wampee leaves screened in step (1), add 9 times of water for beating; adjust cellulase concentration to 120, adjust pectinase concentration to 60ppm, enzymolysis at 35°C After 3 hours, the yellow skin leaf juice is obtained;

[0059] Ⅱ. Preparation of wampee fruit juice: Take 2.5kg of the wampee fruit screened in step (1), add water for beating according to the material-to-water ratio of 1:1, adjust the cellulase concentration to 300ppm, and adjust the pectinase concentration to 150ppm, 35 Enzymolysis at ℃ for 3 hours to obtain wampeskin juice;

[0060] (3) Separate fermentation in the early stage:

[0061] 1. the pre-fermentation of the wampeskin leaf juice: the wampeskin lea...

Embodiment 3

[0070] (1) Screening of yellow skin leaves and yellow skin fruits

[0071] Screen the mature and insect-free yellow-skin leaves and yellow-skinned fruits, wash them with clean water and set aside.

[0072] (2) Preparation of fermented juice:

[0073] Ⅰ. Preparation of wampee leaf juice: take 500 g of wampee leaves screened in step (1), add 9 times of water for beating; adjust cellulase concentration to 120, adjust pectinase concentration to 60ppm, enzymolysis at 35°C After 3 hours, the yellow skin leaf juice is obtained;

[0074] Ⅱ. Preparation of wampee fruit juice: Take 2.5kg of the wampee fruit screened in step (1), add water for beating according to the material-to-water ratio of 1:1, adjust the cellulase concentration to 300ppm, and adjust the pectinase concentration to 150ppm, 35 Enzymolysis at ℃ for 3 hours to obtain wampeskin juice;

[0075] (3) Separate fermentation in the early stage:

[0076] 1. the pre-fermentation of the wampeskin leaf juice: the wampeskin lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com