Titanium sub-oxide multi-dimensional coated titanium electrode and preparation method thereof

A titanium dioxide, coated electrode technology, applied in the field of electrochemistry, can solve problems such as chemical stability and oxygen evolution overpotential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

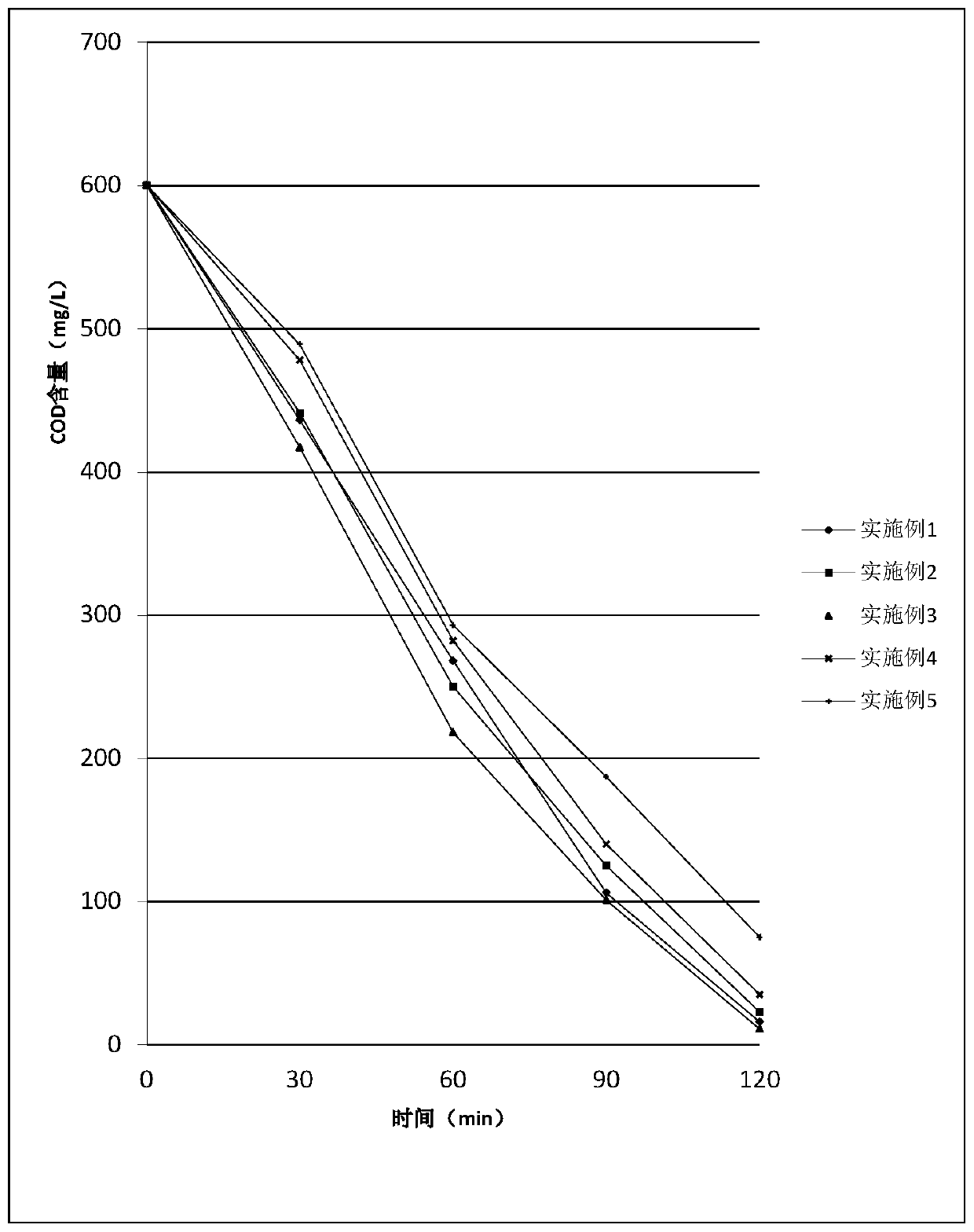

Examples

Embodiment 1

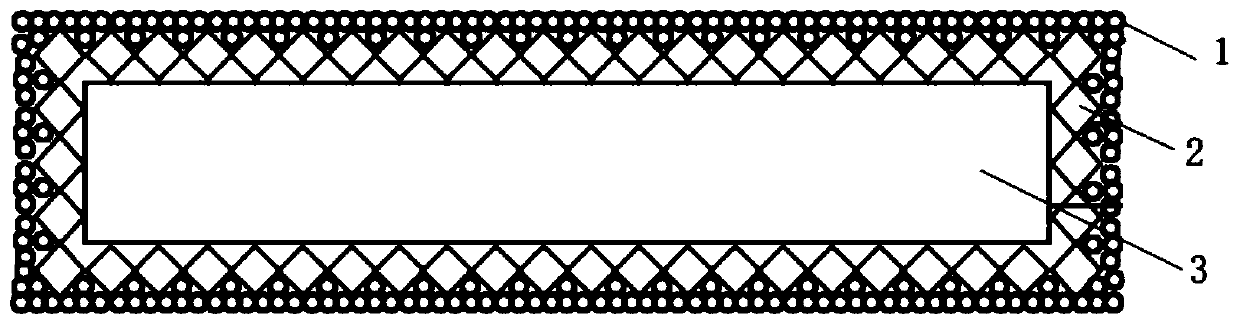

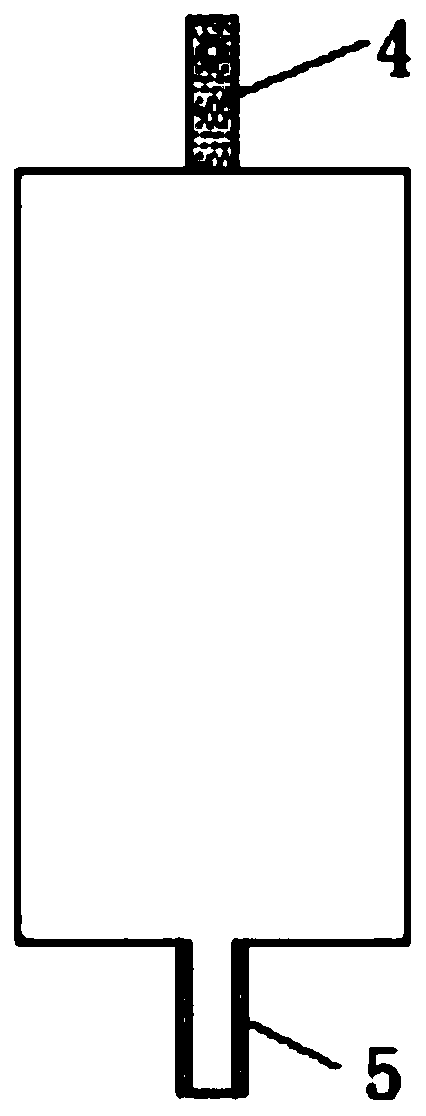

[0031] This embodiment provides a titanium suboxide multi-dimensional coated electrode, which includes a titanium substrate 2 and a metal oxide 1. The metal oxide 1 is attached to the titanium substrate 2. A gas introduction cavity 3 is provided in the titanium substrate 2. The titanium base 2 is provided with a wiring lug 4 and an air inlet channel 5, and the air inlet channel 5 is in communication with the gas introduction cavity 3. In this embodiment, the titanium substrate 2 is a high-purity titanium plate.

[0032] The preparation method of the titanium suboxide multi-dimensional coating electrode is:

[0033] S1. Put the high-purity titanium plate into 5wt% oxalic acid solution, heat to 65℃, keep for 30min, and perform etching treatment to remove oil stains and surface oxide film; then use ultrasonic cleaning to fully remove the residue on the high-purity titanium plate Attachments to make the high-purity titanium plate form a pitted surface;

[0034] S2. Mix ruthenium trichl...

Embodiment 2

[0038] This embodiment provides a titanium suboxide multi-dimensional coated electrode, which includes a titanium substrate 2 and a metal oxide 1. The metal oxide 1 is attached to the titanium substrate 2. A gas introduction cavity 3 is provided in the titanium substrate 2. The titanium base 2 is provided with a wiring lug 4 and an air inlet channel 5, and the air inlet channel 5 is in communication with the gas introduction cavity 3. In this embodiment, the titanium substrate 2 is a porous titanium plate.

[0039] The preparation method of the titanium suboxide multi-dimensional coating electrode is:

[0040] S1. Put the porous titanium plate into a 2wt% dilute hydrochloric acid solution, heat it to 70°C, keep it for 60 minutes, and perform an etching treatment to remove oil stains and surface oxide film; then ultrasonic cleaning is used to fully remove the residual on the porous titanium plate Attachment, make the porous titanium plate form a pitted surface;

[0041] S2. Mix ruth...

Embodiment 3

[0045] This embodiment provides a titanium suboxide multi-dimensional coated electrode, which includes a titanium substrate 2 and a metal oxide 1. The metal oxide 1 is attached to the titanium substrate 2. A gas introduction cavity 3 is provided in the titanium substrate 2. The titanium base 2 is provided with a wiring lug 4 and an air inlet channel 5, and the air inlet channel 5 is in communication with the gas introduction cavity 3. In this embodiment, the titanium substrate 2 is a sponge titanium plate.

[0046] The preparation method of the titanium suboxide multi-dimensional coating electrode is:

[0047] S1. Put the titanium sponge plate into a 5wt% dilute sulfuric acid solution, heat it to 90°C, keep it for 35 minutes, and perform an etching treatment to remove oil stains and oxide film on the surface; then use ultrasonic cleaning to fully remove the residual on the titanium sponge plate Attachment, make the sponge titanium plate pitted;

[0048] S2. Mix antimony trichloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com