Bismuth ferrite-barium titanate based high-temperature lead-free piezoelectric ceramic with low dielectric loss and high-temperature stability and preparation method thereof

A high-temperature stability, lead-free piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Low piezoelectric constant, difficult polarization and other problems, to achieve the effect of simple process and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Formulation (b) ingredients:

[0028] (Bi 0.995 La 0.005 )(Fe 0.97 Ga 0.03 )O 3 -0.25BaTiO 3 +0.01Bi(Mg 2 / 3 Nb 1 / 3 )O 3 +0.03Bi(Zn 0.5 Ti0.5 )O 3 +0.01NdCoO 3 +0.01Ba(W 0.5 Cu 0.5 )O 3 +0.01Li 2 CO 3 +0.01MnCO 3 , the preparation method comprises the following steps:

[0029] (1) to analyze pure Bi 2 o 3 , Fe 2 o 3 , La 2 o 3 , Ga 2 o 3 、BaCO 3 、TiO 2 , MgO, Nb 2 o 3 , ZnO, Nd 2 o 3 、Co 2 o 3 、WO 3 , CuO, Li 2 CO 3 , MnCO 3 As raw materials, according to the formula ratio for batching;

[0030] (2) Use absolute ethanol as the medium to ball mill the mixed powder of step (1) for 24 hours, then dry at 100°C / 6 hours; then put the powder into a high-alumina crucible for compaction, cover, and then In the muffle furnace, the temperature was raised to 800°C at a rate of 250°C / h, and the temperature was kept for 4 hours to synthesize, and the temperature was lowered to below 200°C before being taken out;

[0031] (3) The powder synthesize...

Embodiment 2

[0039] Formulation (a) ingredients:

[0040] Bi(Fe 0.97 Ga 0.03 )O 3 -0.25BaTiO 3 +0.01Bi(Ti 0.5 Mg 0.5 )O 3 +0.03Bi(Zn 0.5 Ti 0.5 )O 3 +0.01NdCoO 3 +0.01Li 2 CO 3 +0.005CuO+0.01MnCO 3 ,

[0041] The preparation method comprises the following steps:

[0042] (1) to analyze pure Bi 2 o 3 , Fe 2 o 3 , Ga 2 o 3 、BaCO 3 、TiO 2 , MgO, ZnO, Nd 2 o 3 、Co 2 o 3 , CuO, Li 2 CO 3 , MnCO 3 As raw materials, according to the formula ratio for batching;

[0043] Other steps are the same as in Example 1, and the sintering temperature is 970°C.

[0044] The performance measurements are as follows:

[0045] d 33 (pC / N)

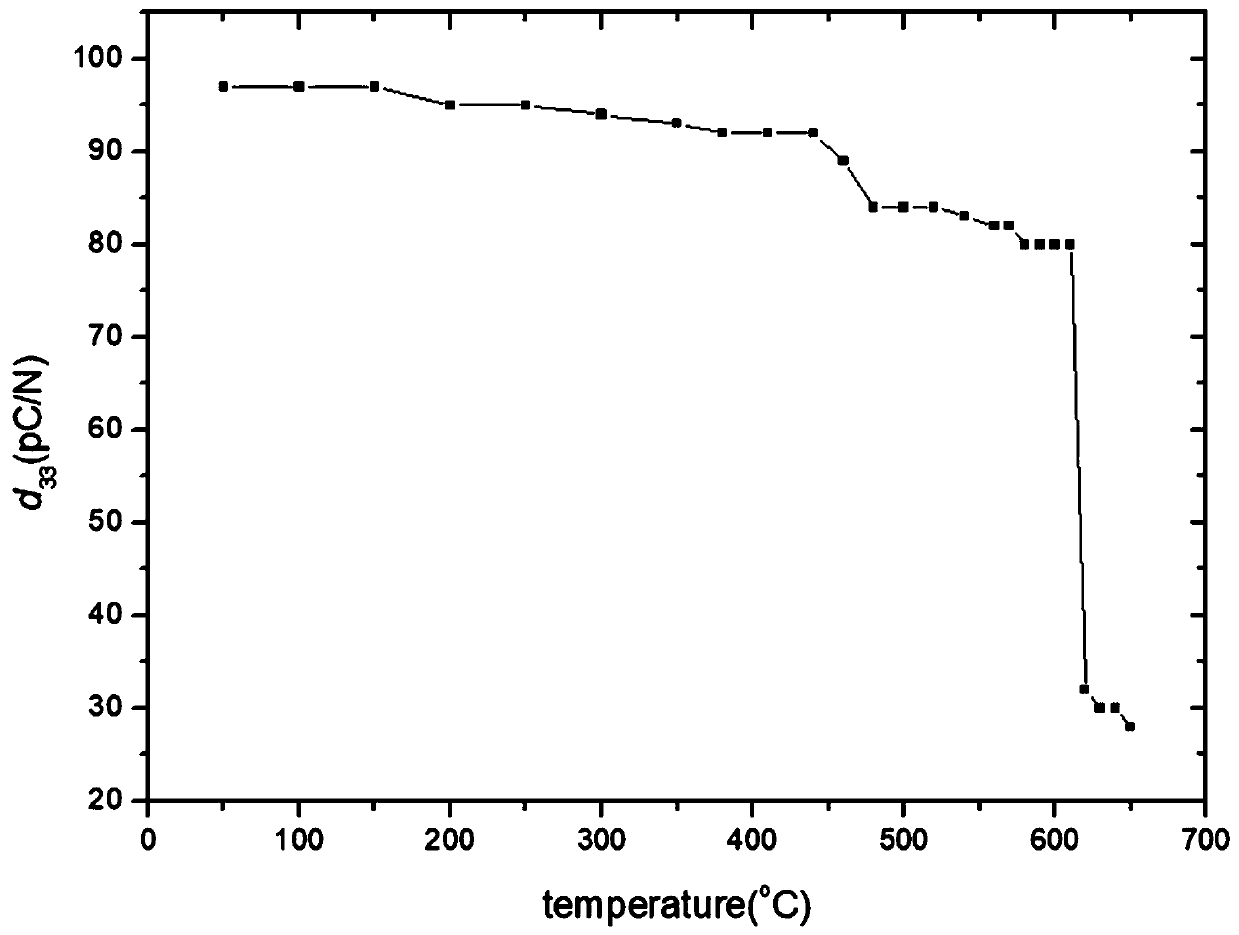

[0046] from figure 1 It can be seen in the figure that after the ceramic sheet is polarized at 150°C and 6000V / mm electric field, d 33 =102pC / N piezoelectric performance, there is a step at 440°C depolarization, with the increase of depolarization temperature, there is d at 610°C 33 = 80pC / N piezoelectric performance.

Embodiment 3

[0048] Formulation (b) ingredients:

[0049] Bi(Fe 0.98 sc 0.02 )O 3 -0.3BaTiO 3 +0.025Bi(Zn 2 / 3 V 1 / 3 )O 3 +0.025Bi(Zn 0.5 Ti 0.5 )O 3 +0.01NdCoO 3 +0.01Li 2 CO 3 +0.01MnCO 3 ,

[0050] The preparation method comprises the following steps:

[0051] (1) to analyze pure Bi 2 o 3 , Fe 2 o 3 、Sc 2 o 3 、BaCO 3 、TiO 2 , ZnO, V 2 o 5 、Nd 2 o 3 、Co 2 o 3 , Li 2 CO 3 , MnCO 3 As raw materials, according to the formula ratio for batching;

[0052] Other steps are the same as in Example 1.

[0053] The performance measurements are as follows:

[0054] d 33 (pC / N)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com