Method for preparing ethylene copolymer

A technology for the polymerization of ethylene copolymers and olefins, which is applied in the field of preparation of ethylene copolymers, can solve problems such as complex catalyst preparation processes, and achieve the effects of low cost, easy industrialization, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

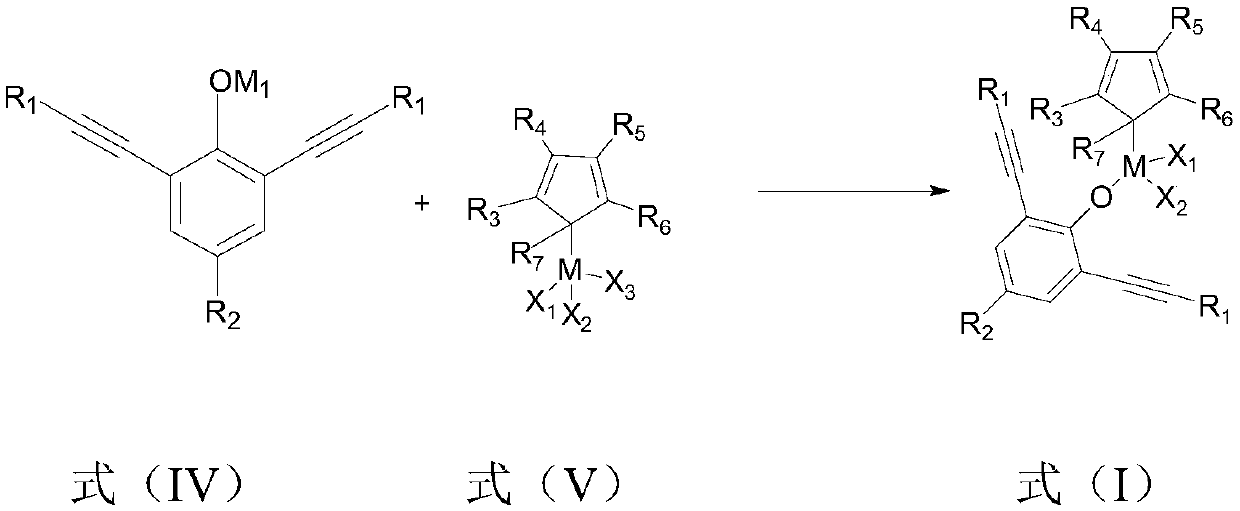

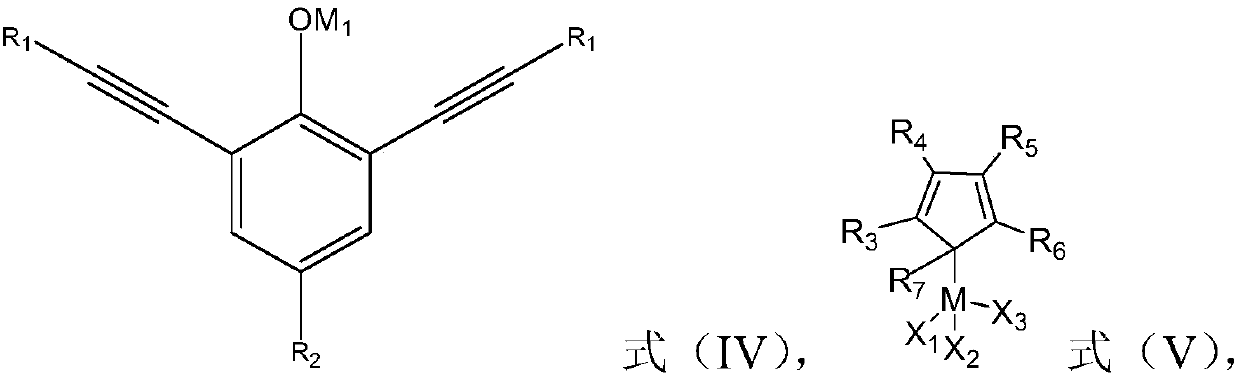

[0017] The present invention provides a method for preparing ethylene copolymer, wherein the method comprises: under olefin polymerization conditions, in the presence of an inert solvent, contacting ethylene, a comonomer and a catalyst, wherein the catalyst contains the formula ( I) post-metallocene catalyst precursors, borides and alkylaluminum compounds based on diacetylenylphenols,

[0018]

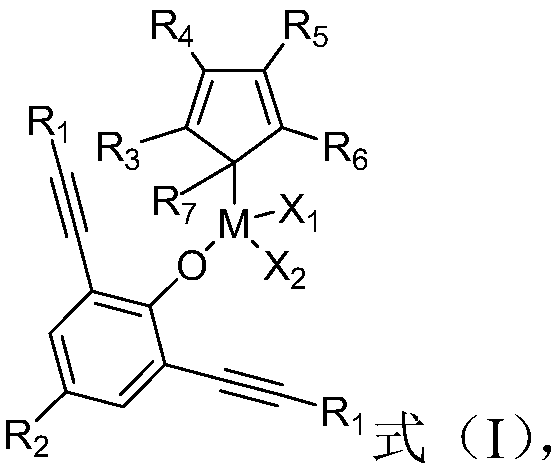

[0019] In formula (I), R 1 for hydrogen, C 1 -C 20 straight-chain or branched-chain alkyl or trimethylsilyl; R 2 for hydrogen, C 1 -C 20 straight-chain or branched-chain alkyl or phenyl; R 3 , R 4 , R 5 , R 6 and R 7 for hydrogen or C 1 -C 20 straight-chain or branched-chain alkyl; M is one of titanium, zirconium and hafnium; X 1 and x 2 The same or different, each independently halogen.

[0020] Among them, the C 1 -C 20 Specific examples of straight-chain or branched-chain alkyl groups may include, but are not limited to: methyl, ethyl, n-propyl, isopropyl, n-butyl...

preparation example 1

[0064] This preparation example is used to illustrate the preparation of the post-metallocene catalyst precursor with the structure represented by formula (II).

[0065] Dissolve 4-tert-butyl-2,6-bis(trimethylsilylacetylene)phenol (3.00mmol) in 30mL ether solvent, add n-hexane containing n-butyllithium to the solution at -78°C The solution (the concentration of n-butyllithium in the n-hexane solution is 1.67M, and the amount of n-butyllithium used is 3.00mmol) was reacted for 1 hour, returned to 25° C., and continued to react for 15 minutes. A compound having a structure represented by formula (VII) is obtained.

[0066]

[0067] At -78 ° C, the solution of the compound containing the structure shown in the formula (VII) obtained above was transferred to the titanium metal complex (3.00 mmol) containing the cyclopentadienyl group of the structure shown in the formula (VIII) through a double angle needle in ether solution (the amount of ether used is 30 mL), and reacted at ...

preparation example 2

[0072] This preparation example is used to illustrate the preparation of the post-metallocene catalyst precursor with the structure represented by formula (II).

[0073] Dissolve 4-tert-butyl-2,6-bis(trimethylsilylacetylene)phenol (3.00mmol) in 30mL of dichloromethane solvent, and add n-butyllithium to the solution at -78°C n-hexane solution (the concentration of n-butyllithium in the n-hexane solution is 1.67M, the amount of n-butyllithium used is 3.00mmol) and then reacted for 1 hour, returned to 20°C, and continued to react for 15 minutes. A compound having a structure represented by formula (VII) is obtained.

[0074] At -78°C, the solution of the compound containing the structure shown in the formula (VII) obtained above was transferred to the titanium metal complex (3.00 mmol) containing the cyclopentadienyl group of the structure shown in the formula (VIII) through a double angle needle in dichloromethane solution (the amount of dichloromethane used is 30 mL), and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com