Gadolinium-rich nickel-based alloy material for reactor spent fuel storage and preparation method thereof

A nickel-based alloy and spent fuel technology, applied in the fields of nickel-based neutron absorption materials and preparation, nickel-based alloy materials and preparation fields, can solve the limitations of the application and development of neutron absorption materials, the complex process of radiation resistance, hot ductility It can reduce problems such as reducing the cost of raw materials, and achieve the effect of excellent processability, corrosion resistance and thermal processing performance, and reduced raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, a method for preparing a gadolinium-rich nickel-based alloy material for reactor spent fuel storage includes the following steps:

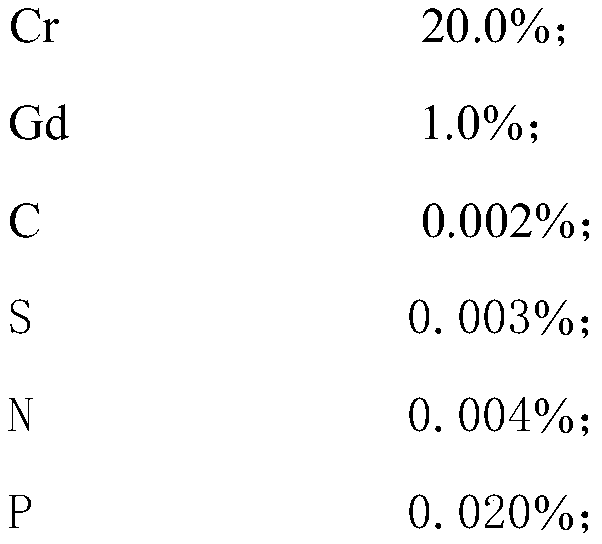

[0028] a. The vacuum induction smelting process is adopted, and when the raw materials are batched, the raw material ingredients used are composed according to the following mass percentage (%) for raw material batching:

[0029]

[0030]

[0031] Vacuum induction melting is carried out on all raw materials weighed after batching to obtain alloy melt;

[0032] b. Casting the alloy melt prepared in the step a, and then going through the hot forging, hot rolling and annealing heat treatment process of the alloy ingot obtained by casting, and finally obtaining the gadolinium-rich nickel-based alloy material for reactor spent fuel storage bar.

[0033] This embodiment adopts the vacuum induction smelting process, and the (Ni, Cr) 5 After Gd, casting and forming, hot forging, hot rolling, annealing and other processes...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

[0036] In this embodiment, a method for preparing a gadolinium-rich nickel-based alloy material for reactor spent fuel storage includes the following steps:

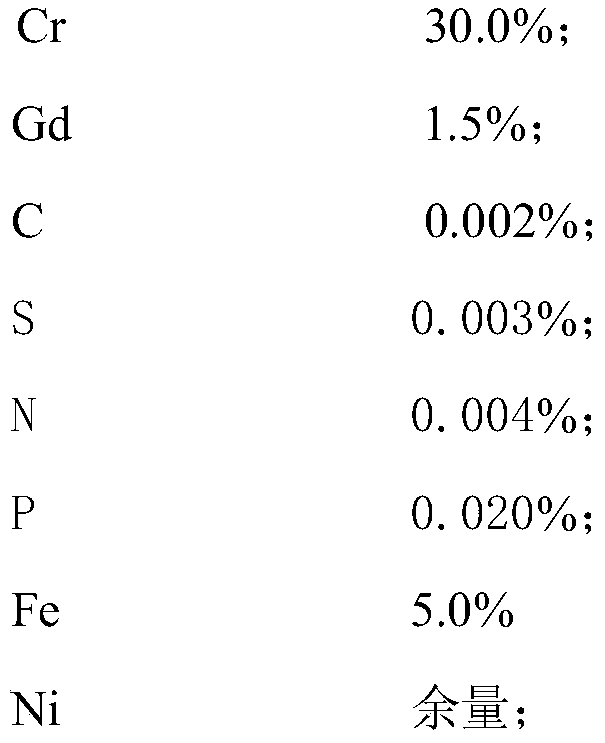

[0037] a. The vacuum induction smelting process is adopted, and when the raw materials are batched, the raw material ingredients used are composed according to the following mass percentage (%) for raw material batching:

[0038]

[0039] Vacuum induction melting is carried out on all raw materials weighed after batching to obtain alloy melt;

[0040] b. This step is the same as in Embodiment 1.

[0041] After experimental testing, the test results show that the room temperature tensile breaking strength of the special steel-based alloy material bar prepared in this embodiment is greater than 700 MPa, and the breaking elongation is greater than 45.0%. The mechanics and corrosion resistance of the special steel base alloy material prepa...

Embodiment 3

[0043] This embodiment is basically the same as the previous embodiment, and the special features are:

[0044] In this embodiment, a method for preparing a special steel-based alloy material for reactor spent fuel storage includes the following steps:

[0045] a. The vacuum induction smelting process is adopted, and when the raw materials are batched, the raw material ingredients used are composed according to the following mass percentage (%) for raw material batching:

[0046]

[0047] Vacuum induction melting is carried out on all raw materials weighed after batching to obtain alloy melt;

[0048] b. This step is the same as in Embodiment 1.

[0049] After experimental testing, the test results show that the room temperature tensile breaking strength of the special steel-based alloy material bar prepared in this embodiment is greater than 650 MPa, and the breaking elongation is greater than 45.0%. The mechanics and corrosion resistance of the special steel base alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com