Method for preparing oxalic acid by electrochemically reducing CO2 in aromatic ester ionic liquid system

An ionic liquid and electrochemical technology, applied in the field of CO2 resource utilization, can solve the problem of low current density and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An electrochemical reduction of CO in an aromatic ester ionic liquid system 2 The method for making oxalic acid, its condition is as follows:

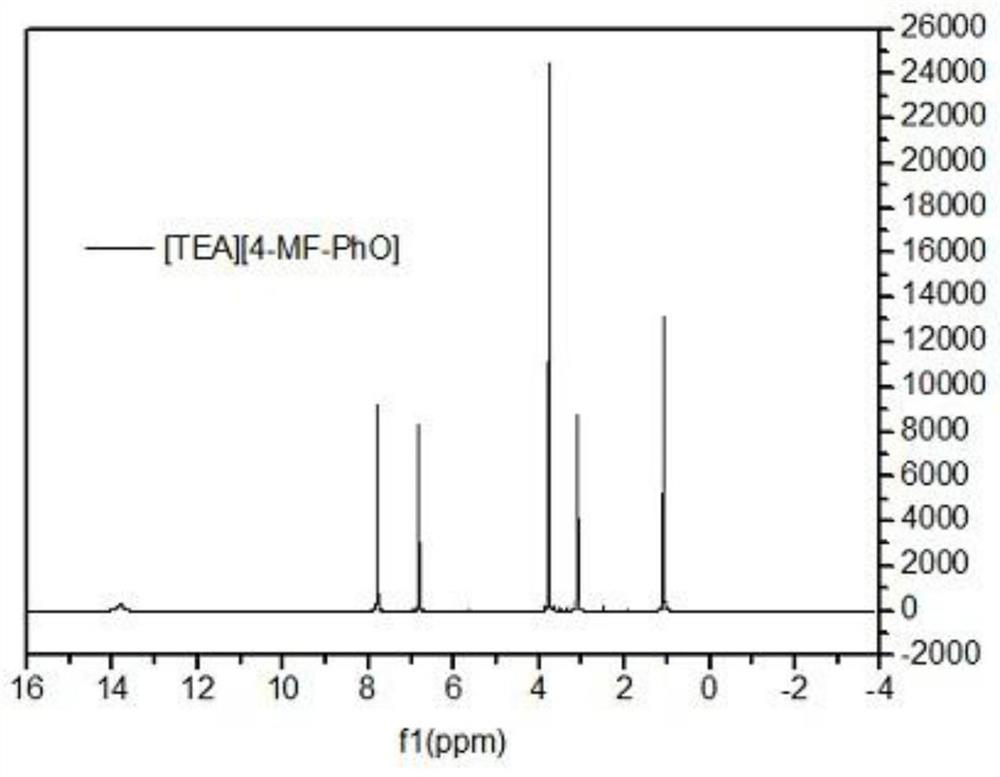

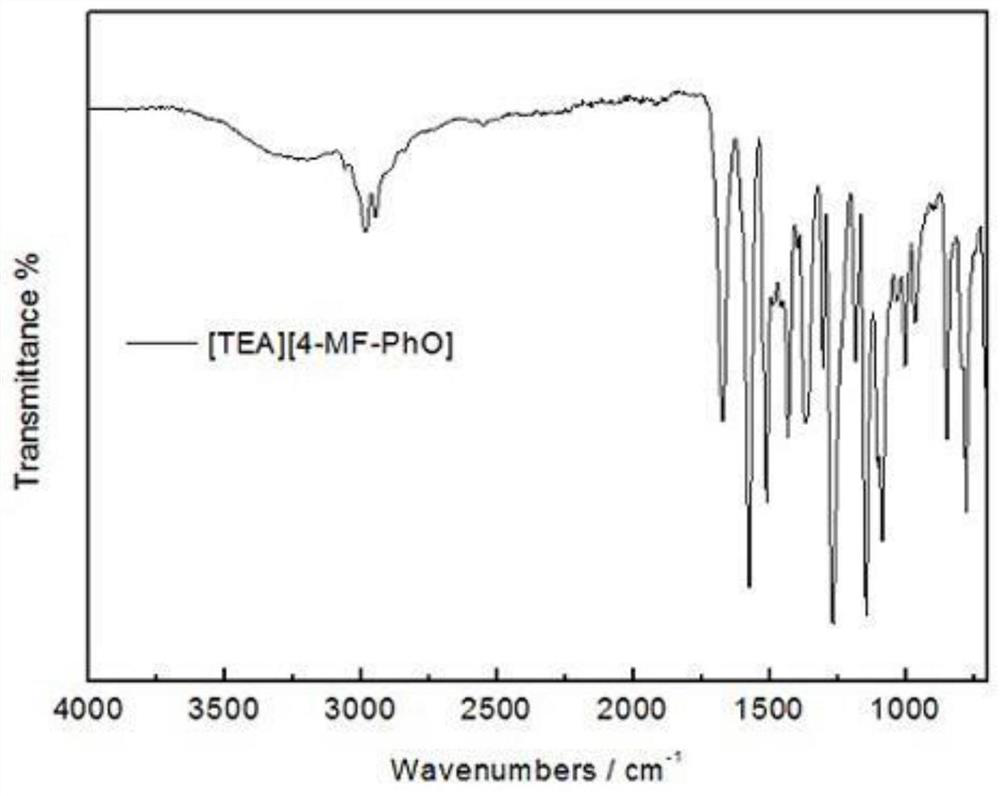

[0029] (1) Synthesis of 4-(methoxycarbonyl)tetraethylammonium phenolate ([TEA][4-MF-PhO])

[0030]The ionic liquid is synthesized by reacting methyl p-hydroxybenzoate and tetraethylammonium hydroxide in a molar ratio of 1:1. The synthesis temperature is 25 °C, stirring under normal pressure conditions, and the reaction time is 10 h. After the reaction, the ethanol and water were removed by rotary evaporation, the temperature was 65°C, the time was 0.5 h; the time was 75°C, the time was 2 h. Finally, it was dried in a vacuum oven at 75 °C for 24 h.

[0031] The synthesis route of [TEA][4-MF-PhO] ionic liquid is as follows:

[0032]

[0033] (2) Electrochemical reduction of CO in [TEA][4-MF-PhO] ionic liquid system 2 Oxalic acid

[0034] Take 0.8442 g [TEA][4-MF-PhO] and dissolve it in acetonitrile to make 30 mL, the solu...

Embodiment 2

[0036] An electrochemical reduction of CO in an aromatic ester ionic liquid system 2 The method for making oxalic acid, its condition is as follows:

[0037] (1) Preparation of 4-(methoxycarbonyl)tetrabutylammonium phenolate ([TBA][4-MF-PhO])

[0038] Methyl p-hydroxybenzoate and tetrabutylammonium hydroxide were synthesized by reacting at a molar ratio of 1:1. The synthesis temperature is 30° C., stirring under normal pressure conditions, and the reaction time is 11 h. After the reaction, the ethanol and water were removed by rotary evaporation, the temperature was 65°C, the time was 0.5 h; the time was 75°C, the time was 2 h. Finally, it was dried in a vacuum oven at 75 °C for 24 h.

[0039] (2) Electrochemical reduction of CO in [TBA][4-MF-PhO] ionic liquid system 2 Oxalic acid

[0040] Take 1.1809 g [TBA][4-MF-PhO] and dissolve it in acetonitrile to make 30 mL, the solution with a concentration of 0.1 mol / L is used as the catholyte, and prepare 0.1 mol / L H 2 SO 4 Th...

Embodiment 3

[0042] An electrochemical reduction of CO in an aromatic ester ionic liquid system 2 The method for making oxalic acid, its condition is as follows:

[0043] (1) Preparation of 4-(methoxycarbonyl)phenol tetraethylphosphonium ([TEP][4-MF-PhO])

[0044] Methyl p-hydroxybenzoate and tetraethylphosphorus hydroxide are synthesized by reacting in a molar ratio of 1:1. The synthesis temperature is 30 °C, stirring under normal pressure conditions, and the reaction time is 12 h. After the reaction, the ethanol and water were removed by rotary evaporation, the temperature was 65°C, the time was 0.5 h; the time was 75°C, the time was 2 h. Finally, it was dried in a vacuum oven at 75 °C for 24 h.

[0045] (2) Electrochemical reduction of CO in [TEP][4-MF-PhO] ionic liquid system 2 Oxalic acid

[0046] Take 4.476 g [TEP][4-MF-PhO] dissolved in dimethyl sulfoxide to make 30 mL, the concentration is 0.5 mol / L solution as catholyte, prepare 0.1 mol / L H 2 SO 4 The dilute solution is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com