IGCC thermoelectric system and method capable of achieving flue gas waste heat deep utilization and input gas cooling

A flue gas waste heat and air intake cooling technology, which is applied in the field of energy saving and emission reduction, can solve the problems of flue gas latent heat discharge, white smoke plume, water loss, etc., and achieve the goal of recovering flue gas waste heat, increasing load rate, and increasing heating capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

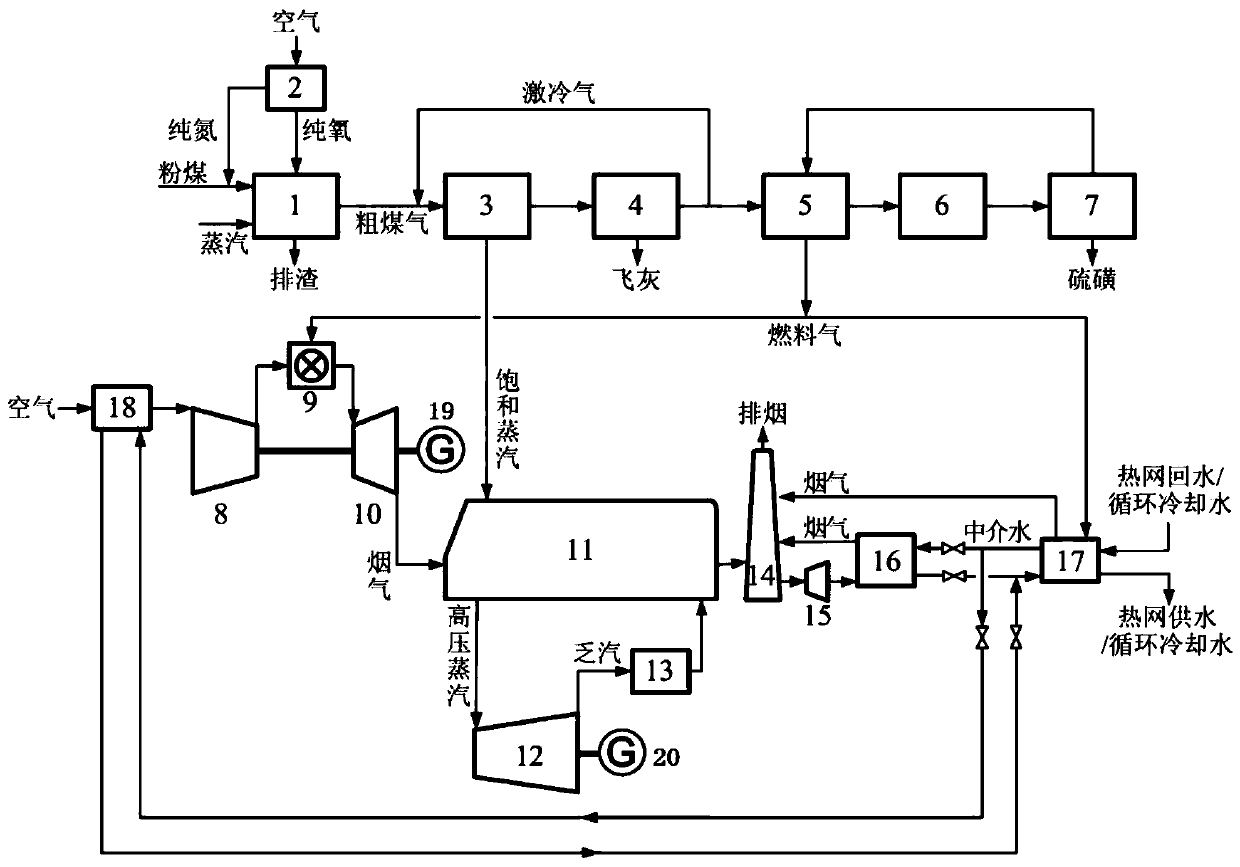

[0039] like figure 1 As shown, the present invention provides an IGCC thermoelectric system that realizes the deep utilization of flue gas waste heat and intake air cooling, including the coal gasification and purification part and the gas-steam combined cycle power generation part;

[0040] The gas-steam combined cycle power generation part includes waste heat boiler 11, steam turbine 12, condensing heat exchanger 16 and gas-type absorption heat pump 17;

[0041] The waste heat boiler 11 is provided with a saturated steam inlet and a flue gas inlet, the high-pressure steam outlet of the waste heat boiler 11 is connected to the steam inlet of the steam turbine 12, and the output shaft of the steam turbine 12 is connected to the second generator 20 for power generation; the flue gas exhaust of the waste heat boiler 11 into the condensing heat exchanger 16, the outlet of the condensing heat exchanger 16 is connected to the inlet of the gas absorption heat pump 17, and the interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com