A wear-resistant and corrosion-resistant sliding cable for mine optoelectronic composite

A photoelectric composite and corrosion-resistant technology, which is applied to power cables with shielding layers/conductive layers, communication cables, insulated cables, etc., can solve problems affecting cable protection life, cable fatigue, shrinkage increase, etc., to ensure communication capacity and transmission distance, increase the cross-section of the ground wire, and reduce the effect of light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

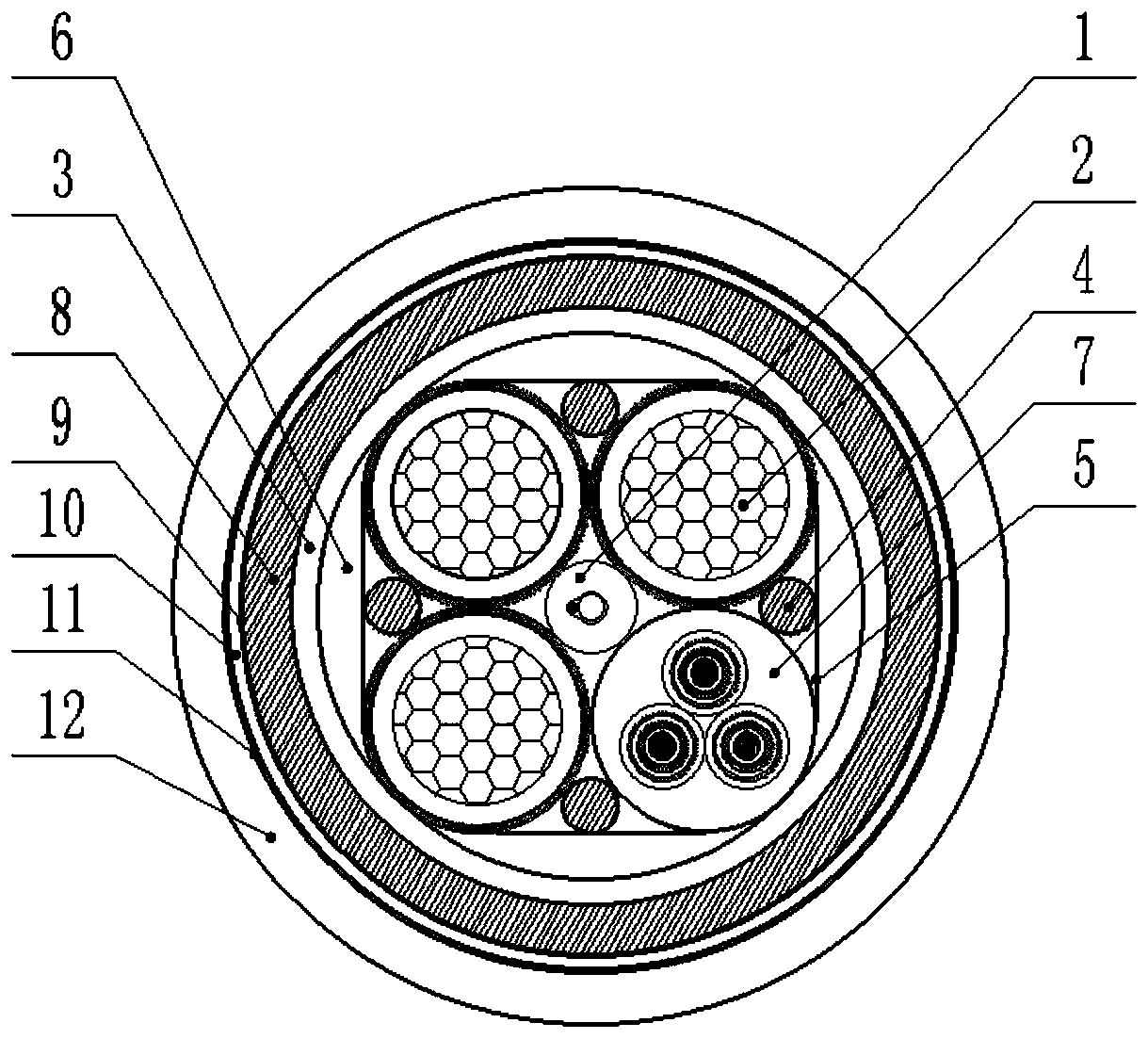

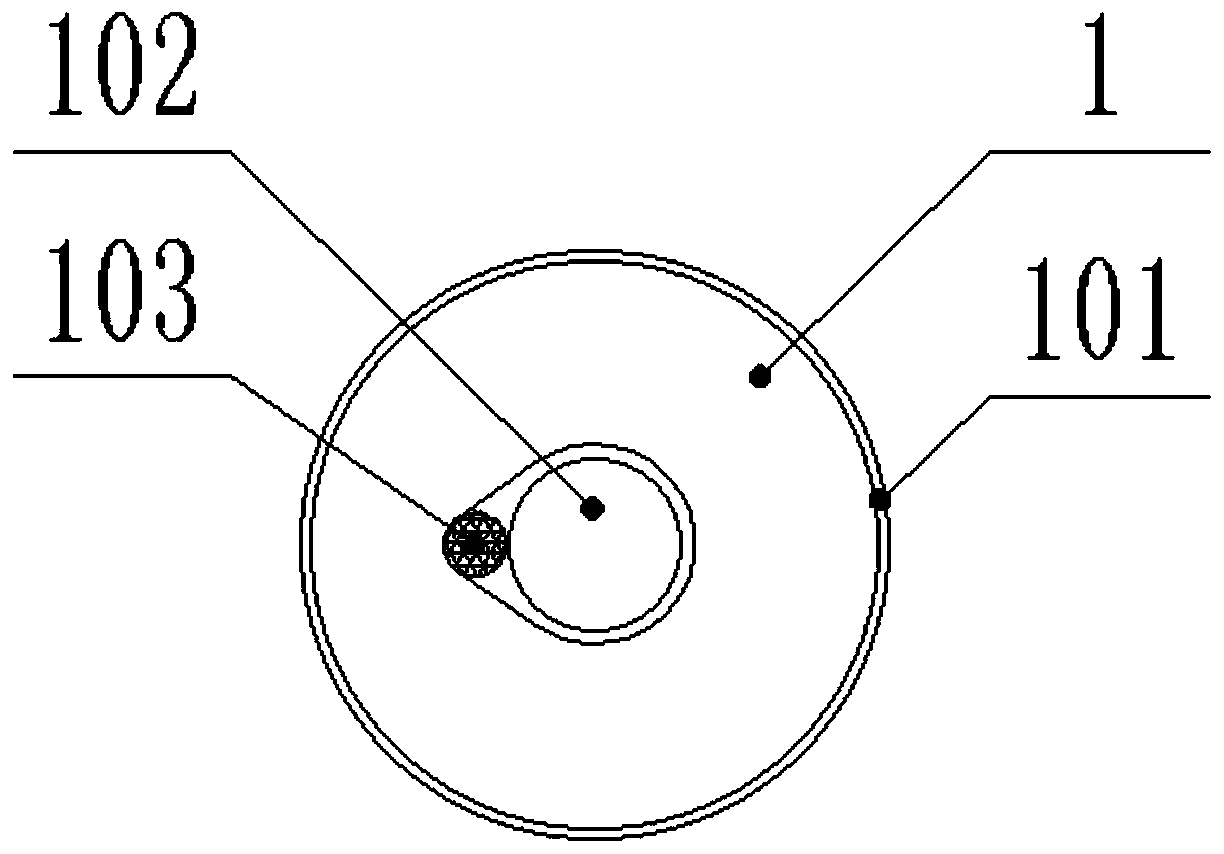

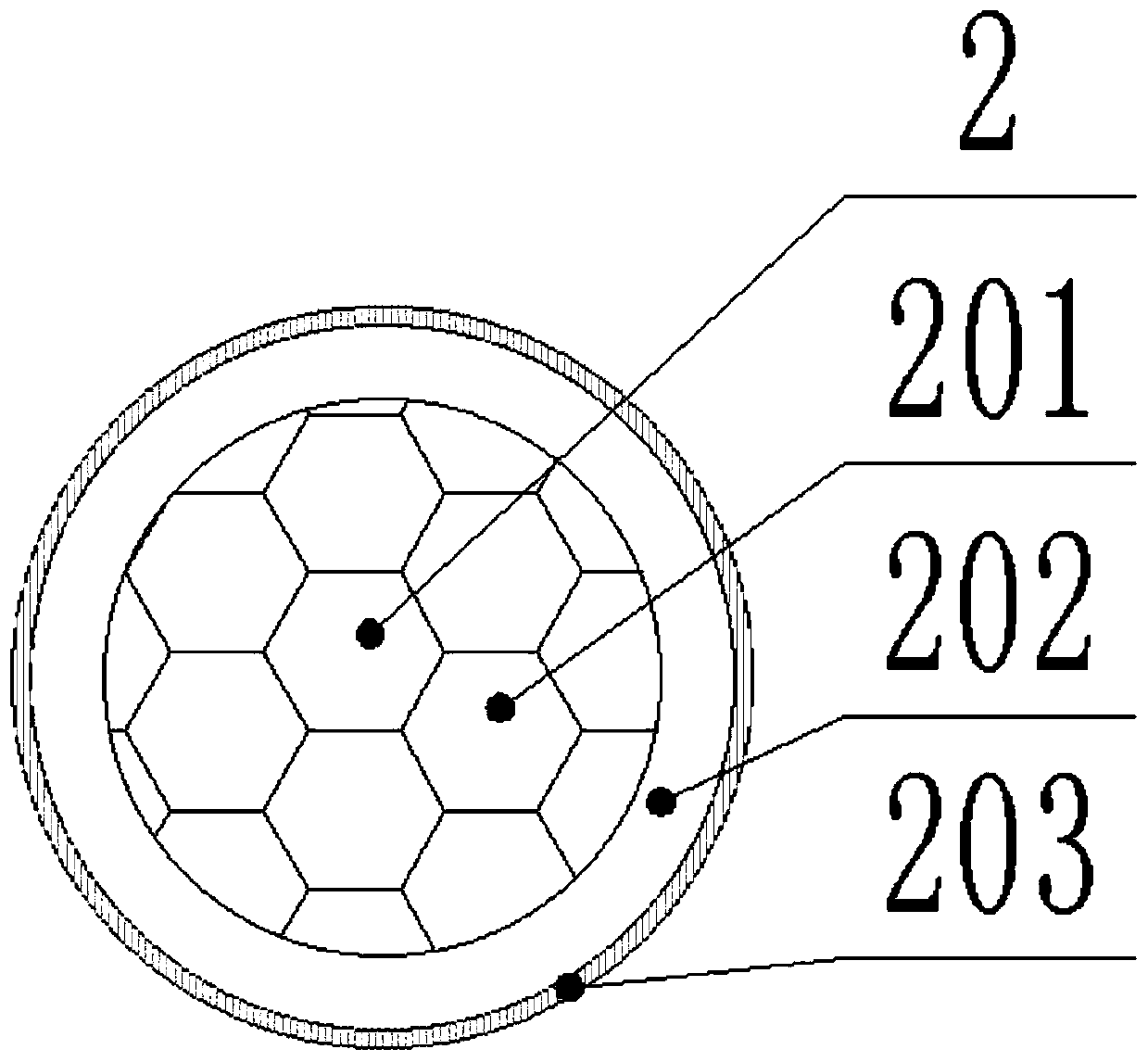

[0070] Such as Figure 1-4 As shown; the wear-resistant and corrosion-resistant sliding cable for mine photoelectric composite of the present embodiment includes functional components, inner sheath 8 and outer sheath 12 from inside to outside in turn; inner sheath 8 and outer sheath 12 are provided with Slip layer; the functional components include an optical fiber group 1 and three power lines 2 twisted around the optical fiber group 1, a control line group 7 and multiple reinforcing strips 4, and the functional components are bundled with high-strength fibers 5 after twisting, The high-strength fibers 5 are fiber ropes 71 with 12 strands crossing forward and backward, bundled at an angle of 45° relative to the radial direction of the cable; the optical fiber group 1 includes steel wires 103, optical fibers 102 and metal sleeves 101, steel wires 103 and optical fibers 102 Covered in the metal sleeve 101, the maximum outer diameter of the single-mode optical fiber is 0.5 times...

Embodiment 2

[0100] Such as Figure 1-4 As shown; the wear-resistant and corrosion-resistant sliding cable for mine photoelectric composite of the present embodiment includes functional components, inner sheath 8 and outer sheath 12 from inside to outside in turn; inner sheath 8 and outer sheath 12 are provided with Slip layer; the functional components include an optical fiber group 1 and three power lines 2 twisted around the optical fiber group 1, a control line group 7 and multiple reinforcing strips 4, and the functional components are bundled with high-strength fibers 5 after twisting, The high-strength fiber 5 is a fiber rope 71 with 4 strands crossing forward and backward, and is bundled at an angle of 30° relative to the radial direction of the cable; the optical fiber group 1 includes steel wire 103, optical fiber 102 and metal sleeve 101, steel wire 103 and optical fiber 102. Covered in the metal sleeve 101, the maximum outer diameter of the single-mode optical fiber is 0.3 time...

Embodiment 3

[0130] Such as Figure 1-4 As shown; the wear-resistant and corrosion-resistant sliding cable for mine photoelectric composite of the present embodiment includes functional components, inner sheath 8 and outer sheath 12 from inside to outside in turn; inner sheath 8 and outer sheath 12 are provided with Slip layer; the functional components include an optical fiber group 1 and three power lines 2 twisted around the optical fiber group 1, a control line group 7 and multiple reinforcing strips 4, and the functional components are bundled with high-strength fibers 5 after twisting, The high-strength fiber 5 is a fiber rope 71 with 8 strands crossing each other in the front and back, and is bundled at an angle of 40° relative to the radial direction of the cable; the optical fiber group 1 includes steel wire 103, optical fiber 102 and metal sleeve 101, steel wire 103 and optical fiber 102 package Covered in the metal sleeve 101, the maximum outer diameter of the single-mode optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com