A kind of device and method for preparing propyl propionate by autothermal recovery reaction distillation

A technology of propyl propionate and reactive distillation, applied in the field of rectification, can solve the problems of energy waste, heat exchange mismatch, insufficient heat utilization, etc., and achieve the effect of reducing energy consumption and condensing heat exchange load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

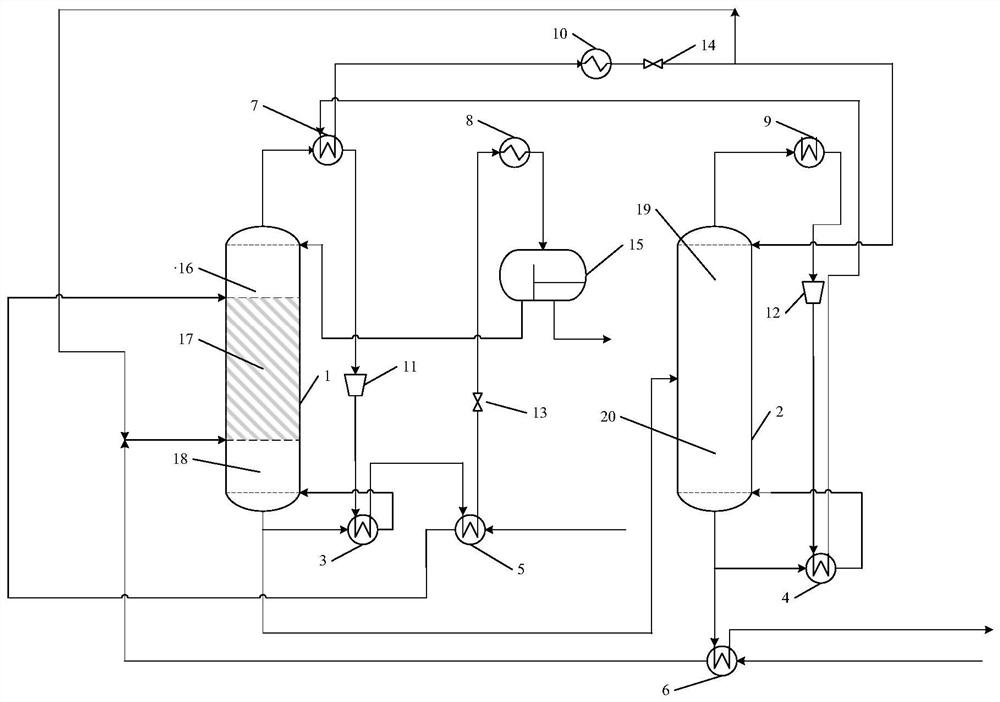

[0032] Attached figure 1 Shown technological process, the reactive distillation tower 1 that adopts altogether 45 trays, propionic acid inlet is the 7th tray, and propanol inlet is the 31st tray; The operation of reactive distillation tower The pressure is 1 atm. The raw material propionic acid is heated to 103°C by the raw material propionic acid preheater 5 at 50 kmol / h, and then fed from the upper part of the reaction section 17 of the reactive distillation column 1, and the raw material propanol is heated by the raw material propanol heat exchanger 6 at 50 kmol / h After reaching 100°C, mix with propanol 10kmol / h returned from the recovery tower top condenser 10, feed from the lower part of the reaction section 17 of the reactive distillation tower (the alkyd feed ratio is 1.2:1), and the raw material is in the strongly acidic cation Under the action of exchange resin, an esterification reaction occurs in the reaction section 17 of the reactive distillation tower to generat...

Embodiment 2

[0037] Attached figure 1 Shown technological process, the reactive distillation tower 1 that adopts altogether 45 trays, propionic acid inlet is the 7th tray, and propanol inlet is the 31st tray; The operation of reactive distillation tower The pressure is 0.5 atm. The raw material propionic acid is heated through the raw material propionic acid preheater 5 at 50 kmol / h to 78° C., feeds from the upper part of the reaction section 17 of the reactive distillation column 1, and the raw material propanol is heated to 50 kmol / h through the raw material propanol heat exchanger 6 to After 77°C, it is mixed with 20 kmol / h of propanol returned from the top condenser 10 of the recovery tower, fed from the lower part of the reaction section 17 of the reactive distillation tower (alkyd feed ratio is 1.4:1), and the raw material is exchanged with strong acidic cations. Under the action of resin, an esterification reaction occurs in the reaction section 17 of the reactive distillation towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com