Ultrasonic-assisted complex enzymatic hydrolysis extraction of Gracilaria polysaccharides and its extraction method

A composite enzymolysis and ultrasonic technology, applied in the direction of fermentation, can solve the problems of high requirements for strong acid extraction equipment, low yield of Jiangli polysaccharide, long extraction time, etc., to shorten the extraction time, high nutritional and health value, and improve the extraction rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

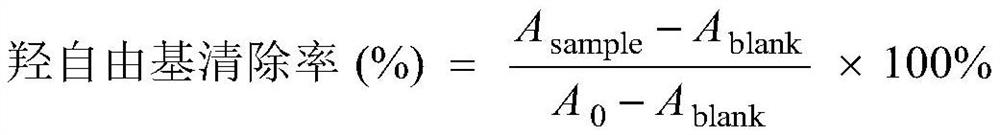

Method used

Image

Examples

Embodiment 1

[0038] Take 1.0g of fine-based Gracilaria powder, add 40mL of disodium hydrogen phosphate-citric acid buffer solution prepared at pH = 5.5, stir on a magnetic stirrer to make the powder fully absorb water and mix evenly, and then place it in a place heated to 55°C In the ultrasonic cleaner, set the ultrasonic time to 40min and the ultrasonic power to 150W for ultrasonic treatment.

[0039] After the ultrasonic treatment, according to the dosage of 3wt% compound enzyme, add 1mL bromelain solution (15mg·mL -1 ) and 1mL cellulase solution (15mg·mL -1 ), and then immediately transferred to a constant temperature water bath at 55°C for enzymolysis for 120 minutes. Here bromelain Bromelain, Zhengzhou Jiuting Chemical Products Co., Ltd. (the same source of bromelain used in the following examples); Cellulase CELLUCLAST 1.5L, Novozymes (China) Biotechnology Co., Ltd. (the cellulose used in the following examples) Enzymes from the same source).

[0040] After enzymolysis, transfer t...

Embodiment 2

[0045] Take 1.0g of fine-based Gracilaria powder, add 100mL of disodium hydrogen phosphate-citric acid buffer solution prepared at pH=5.5, stir on a magnetic stirrer to make the powder fully absorb water and mix evenly, and then place it in a place heated to 55°C In the ultrasonic cleaner, set the ultrasonic time to 40min and the ultrasonic power to 150W for ultrasonic treatment.

[0046] After the ultrasonic treatment, according to the dosage of 3wt% compound enzyme, add 1mL bromelain solution (10mg·mL -1 ) and 1mL cellulase solution (20mg·mL -1 ), and then immediately transferred to a constant temperature water bath at 55°C for enzymolysis for 120 minutes.

[0047] After enzymolysis, transfer to a boiling water bath for 20 minutes, then immediately centrifuge at 5000 rpm for 10 minutes, collect the supernatant, add 3 times the volume of absolute ethanol to the supernatant to precipitate the polysaccharide, and then centrifuge. The condition is 3000rpm, centrifuge for 5min,...

Embodiment 3

[0051] Take 1.0g of fine-based Gracilaria powder, add 80mL of disodium hydrogen phosphate-citric acid buffer solution prepared at pH=5.5, stir on a magnetic stirrer to make the powder fully absorb water and mix evenly, and then place it in a place heated to 55°C In the ultrasonic cleaner, set the ultrasonic time to 20min and the ultrasonic power to 150W for ultrasonic treatment.

[0052] After the sonication, add 1mL bromelain solution (12.5mg·mL -1 ) and 1mL cellulase solution (17.5mg·mL -1 ), and then immediately transferred to a constant temperature water bath at 55°C for enzymolysis for 120 minutes.

[0053] After enzymolysis, transfer to a boiling water bath for 20 minutes, then immediately centrifuge at 5000 rpm for 10 minutes, collect the supernatant, add 3 times the volume of absolute ethanol to the supernatant to precipitate the polysaccharide, and then centrifuge. The condition is 3000rpm, centrifuge for 5min, after the centrifugation, collect the ethanol precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com