Gas Recovery Concentrator

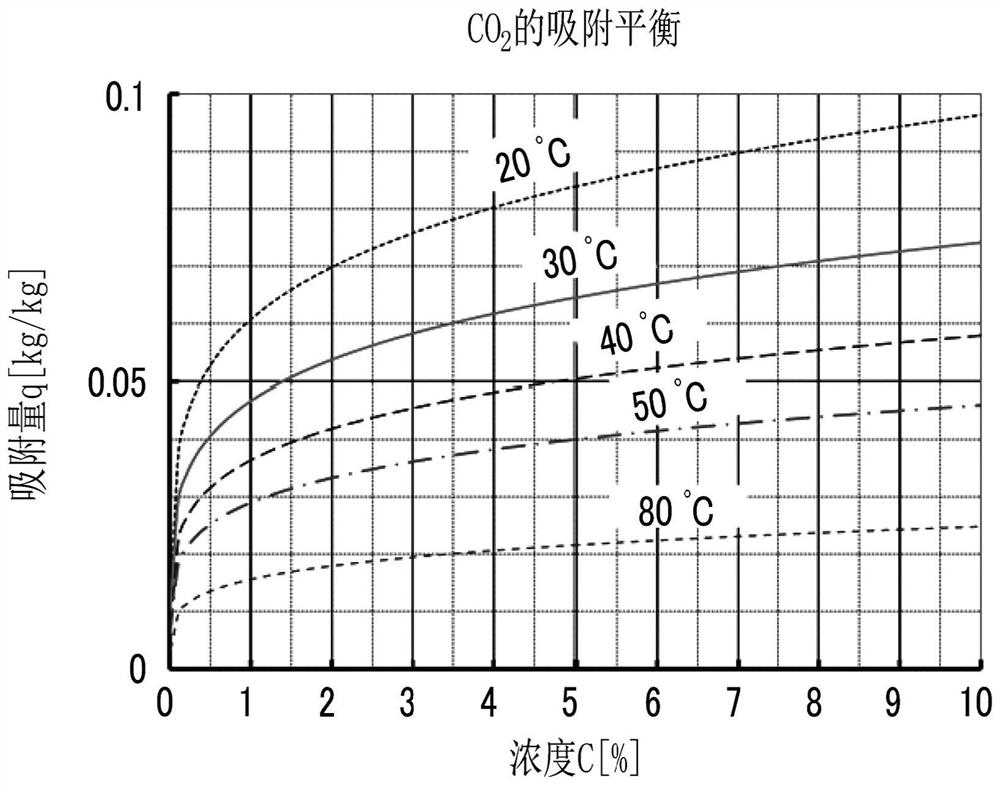

A gas recovery and concentration device technology, which is applied in gas treatment, combustible gas purification, ion exchange treatment devices, etc., can solve the problems of insufficient carbon dioxide recovery rate, concentration concentration, energy recovery and energy saving, etc., to improve adsorption performance and suppress temperature The effect of rising and high-efficiency adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

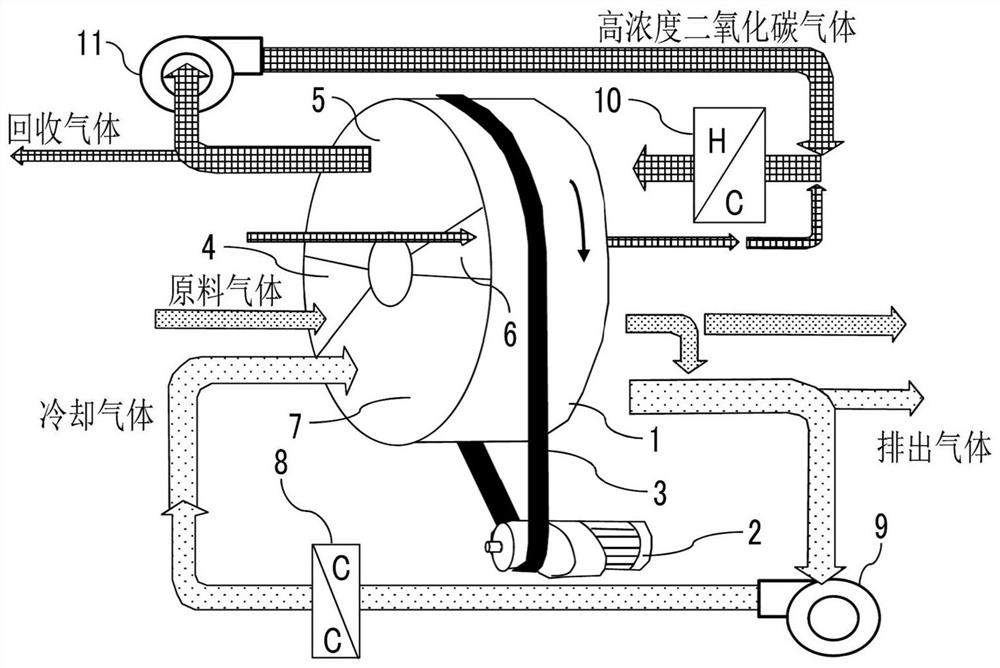

[0112] Figure 4 Example 1 is shown in . As for the honeycomb rotor 12, the 30g / m 2 Coating the coating solution mixed with solid amine particles with a particle size distribution of 0.02 to 0.1 mm and a heat-resistant and water-resistant binder on porous paper, and corrugating the dried sheet (photo 2) to a pitch of 3.0 mm and a height of 2.0mm, and it is wound and rotorized to obtain a volume specific gravity of 150kg / m containing 50% by weight of solid amine particles 3 The honeycomb rotor 12. In the present invention, since steam is used to desorb the adsorbed carbon dioxide, it is not necessary to make the honeycomb rotor 12 flame-resistant. However, in order to ensure shape retention and strength in hot water, it is preferable to mix inorganic fibers such as paper glass fibers or PET. Paper made of synthetic fibers such as , etc. is used as a support body, but if it is a non-woven fabric of synthetic fibers having steam resistance, shape retention, and strength, it is...

Embodiment 2

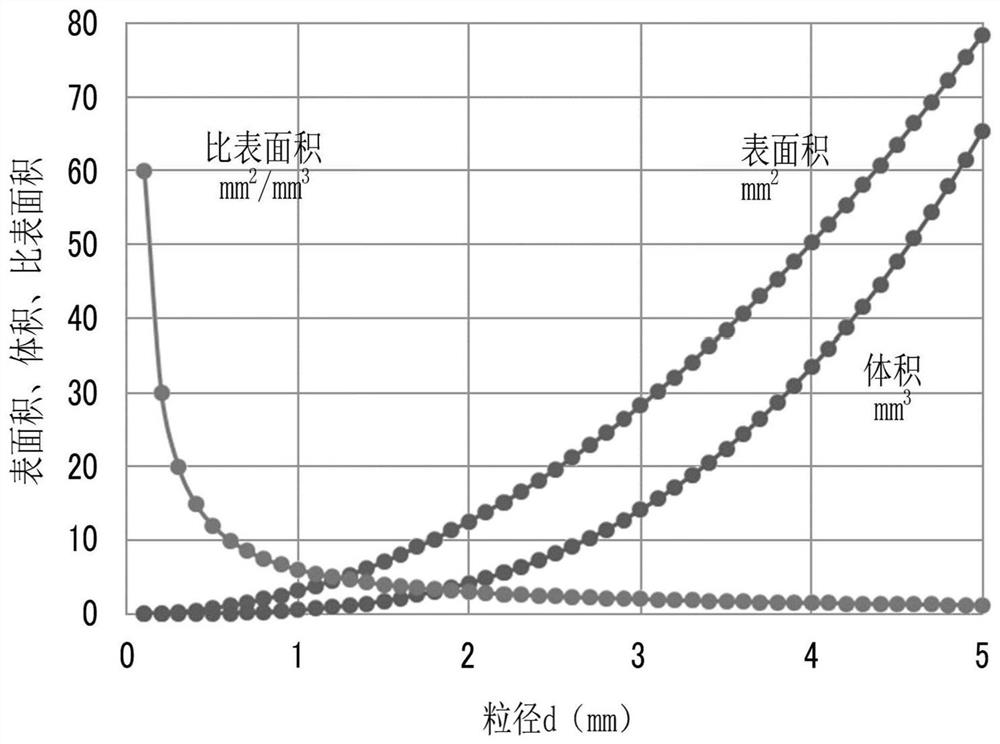

[0119] Figure 5 Example 2 is shown in . On the front and back of the sheet of aluminum foil 25μ, coat heat-resistant, water-resistant epoxy adhesive, use the sheet that is distributed and bonded with 0.3-1.2mm granular amine-based weak base ion-exchange resin particles ( Figure 14 ) corrugated into a pitch of 9mm and a height of 5.6mm, and further coiled or stacked to obtain a load of 240g / m 3 Carbon dioxide enrichment honeycomb rotor 12 of amine-based weak base ion exchange resin.

[0120] The sheet in which the ion exchange resin is distributed and bonded can be produced, for example, by a method such as Japanese Patent Publication Hei 7-16576, but it is not limited to this method.

[0121] The carbon dioxide recovery and concentration device returns to the adsorption area 13 through the adsorption area 13 and the desorption area 14 along the rotation direction of the honeycomb rotor 12 . When the material gas containing carbon dioxide gas, which is pre-treated to cool ...

Embodiment 3

[0127] Figure 6-a , b, c show the embodiment 3 of the situation where a water curtain purification zone is provided. in addition, Figure 6-b for Figure 6-a The A-A cross-section of the view, Figure 6-c for Figure 6-a The direction view in the B-B section of . For the front and rear boundaries of the adsorption area and the desorption area, the settings are as follows Figure 6-a The advantages of the situation of the water injection curtain raw material gas purification zone 15 and the water injection curtain carbon dioxide purification zone 16 shown in , b and c will be described. At the position where the rotor honeycomb moves from the adsorption area to the desorption area, the raw material gas in the void of the honeycomb is brought into the desorption area to reduce the recovery concentration of carbon dioxide. Moreover, at the position where the rotor honeycomb moves from the desorption area to the adsorption area, the high-concentration carbon dioxide gas in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com