Polishing liquid and polishing method

一种研磨液、被研磨的技术,应用在研磨液领域,达到抑制侵蚀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

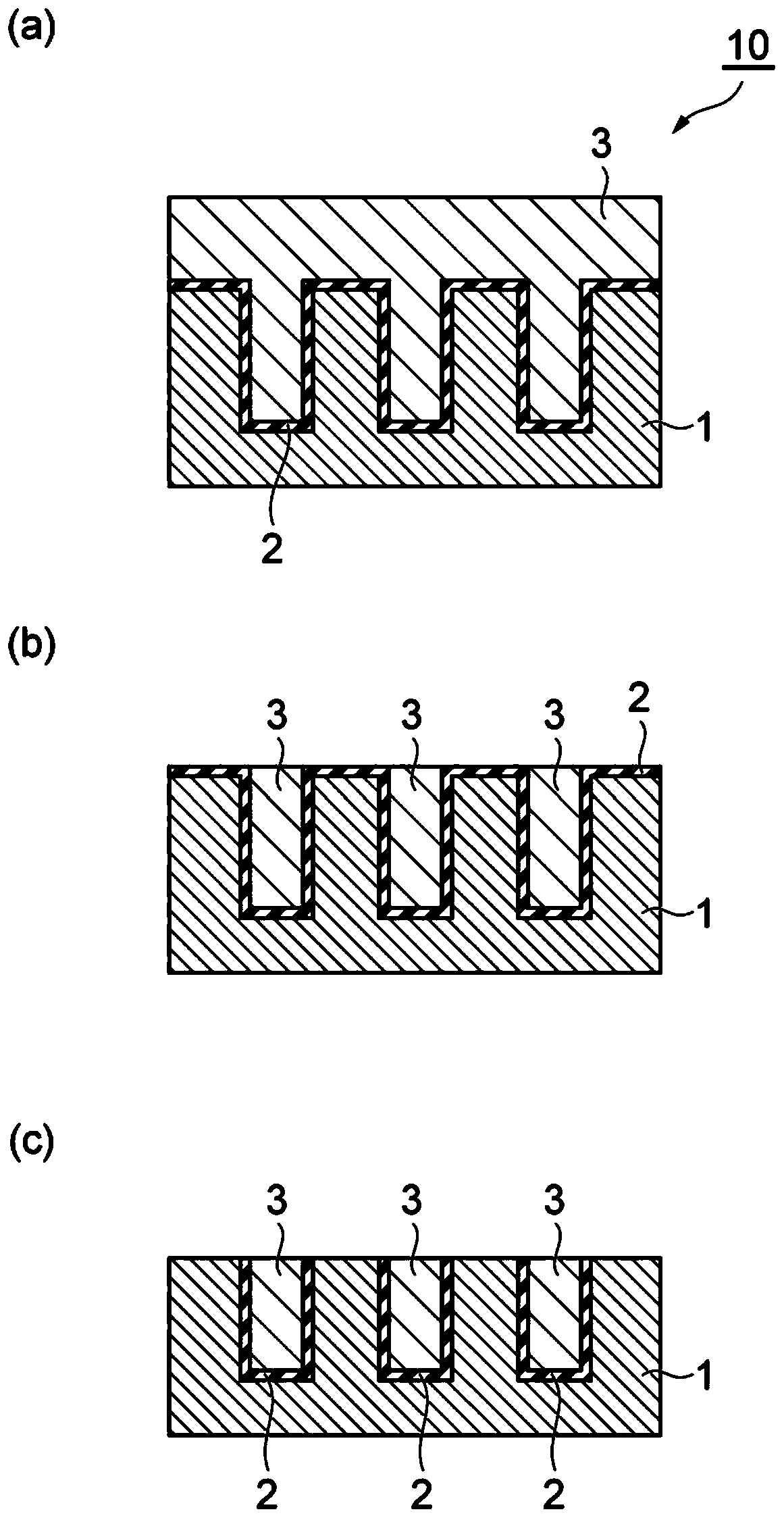

Image

Examples

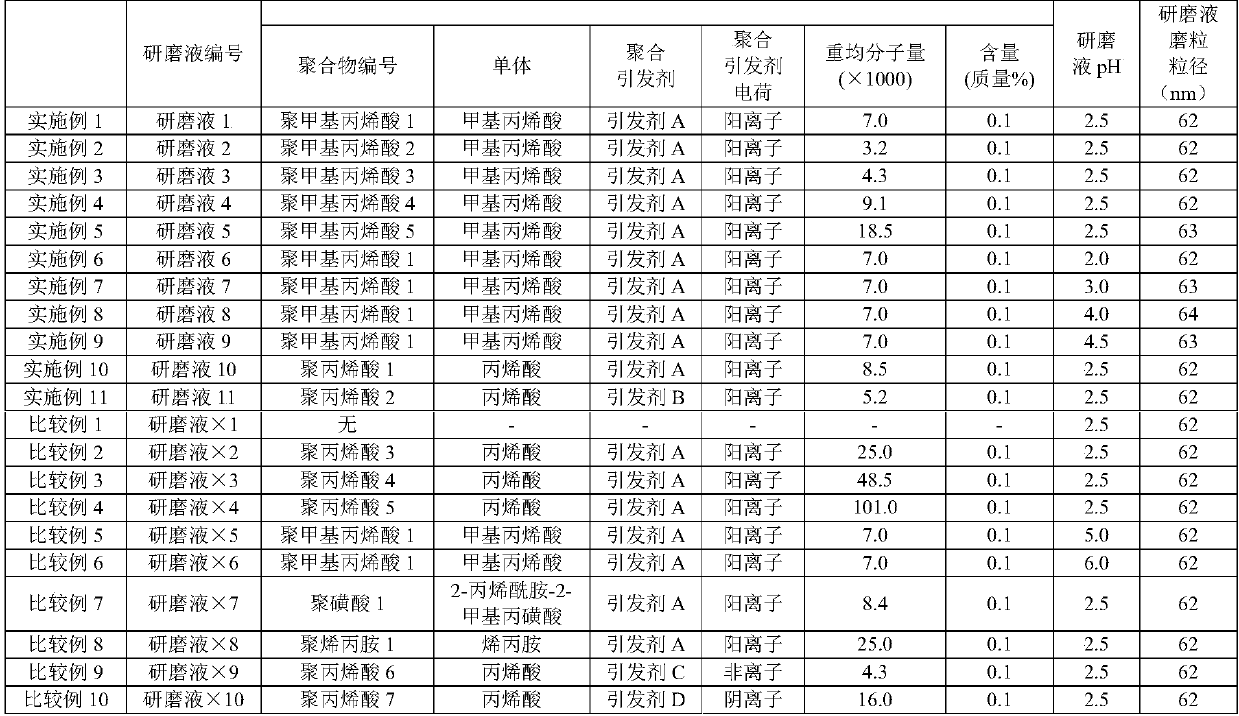

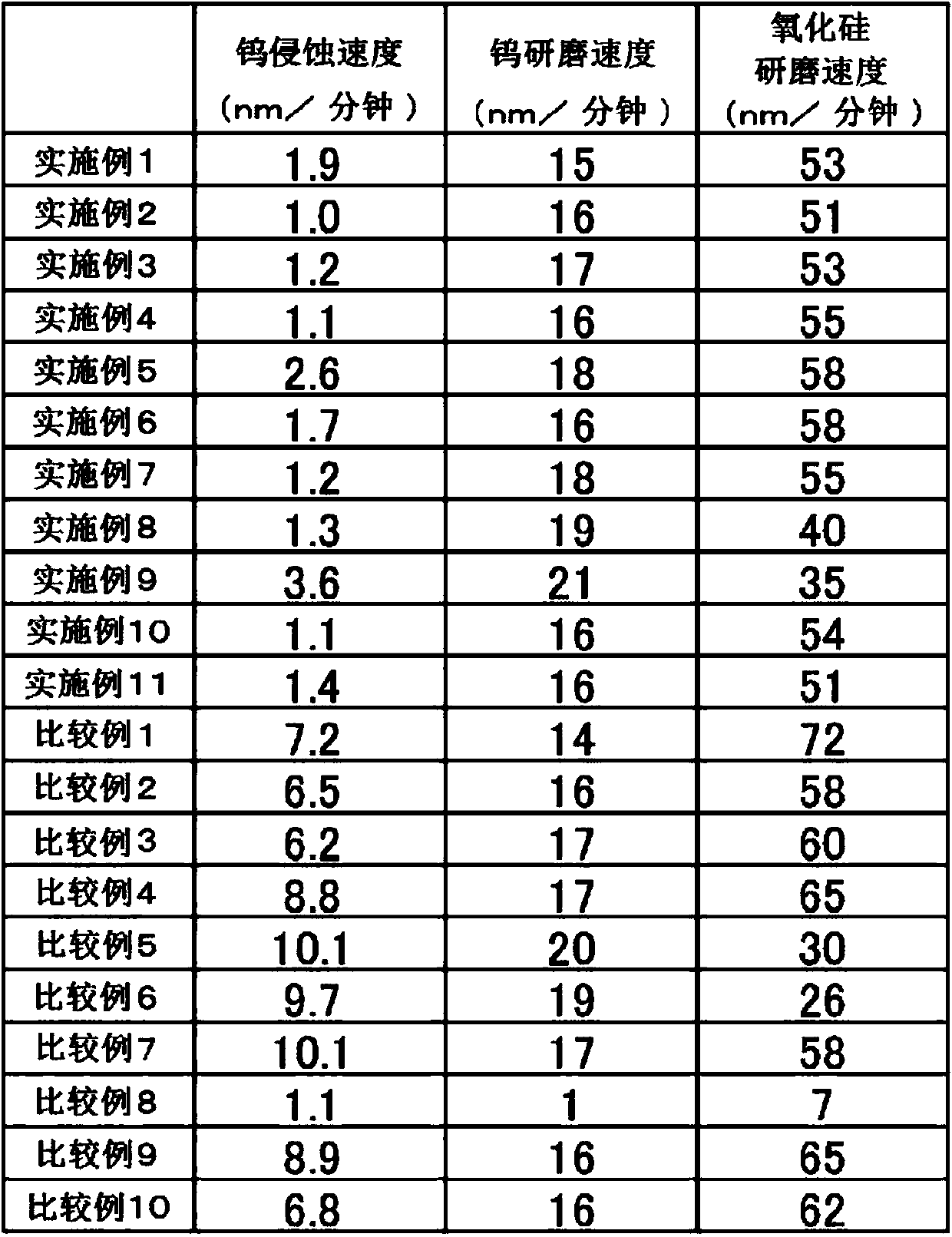

Embodiment 1

[0103] After dissolving 4 g of malic acid in 700 g of deionized water, 1 g of polymethacrylic acid 1 (using 2,2'-azobis[2-(5-methyl-2 -Imidazolin-2-yl) propane] dihydrochloride as a polymerization initiator, polymethacrylic acid with a weight average molecular weight of 7,000 synthesized using methacrylic acid as a monomer) was dissolved to obtain an aqueous solution. After adding 100 g of colloidal silica (aqueous dispersion with a silica content of 20% by mass, pH: 8.1, specific gravity: 1.1, viscosity: 3.5 mPa·s, secondary particle diameter of 60 nm during mixing) to this aqueous solution, 100 g of 30 mass % hydrogen peroxide water was added. Further, after adding an appropriate amount of 25% by mass ammonia water (pH adjuster) to adjust the pH of the polishing liquid to 2.5, the balance of deionized water was added to produce a total amount of 1000 g of polishing liquid 1. The content of abrasive grains in the polishing liquid was 2% by mass, the content of polymethacryli...

Embodiment 2

[0105] Except having used the polymethacrylic acid 2 of the weight average molecular weight 3200 which has a cationic group at the terminal of a main chain, it carried out similarly to Example 1, and the polishing liquid 2 was manufactured.

Embodiment 3

[0107] Except having used the polymethacrylic acid 3 of weight average molecular weight 4300 which has a cationic group at the terminal of a main chain, it carried out similarly to Example 1, and the polishing liquid 3 was manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com