Multifunctional clothing material and preparation method thereof

A multi-functional, clothing technology, applied in the field of clothing materials, can solve the problems of complex production process, high production difficulty, low yield, etc., and achieve the effects of increasing specific surface area, good mechanical properties, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

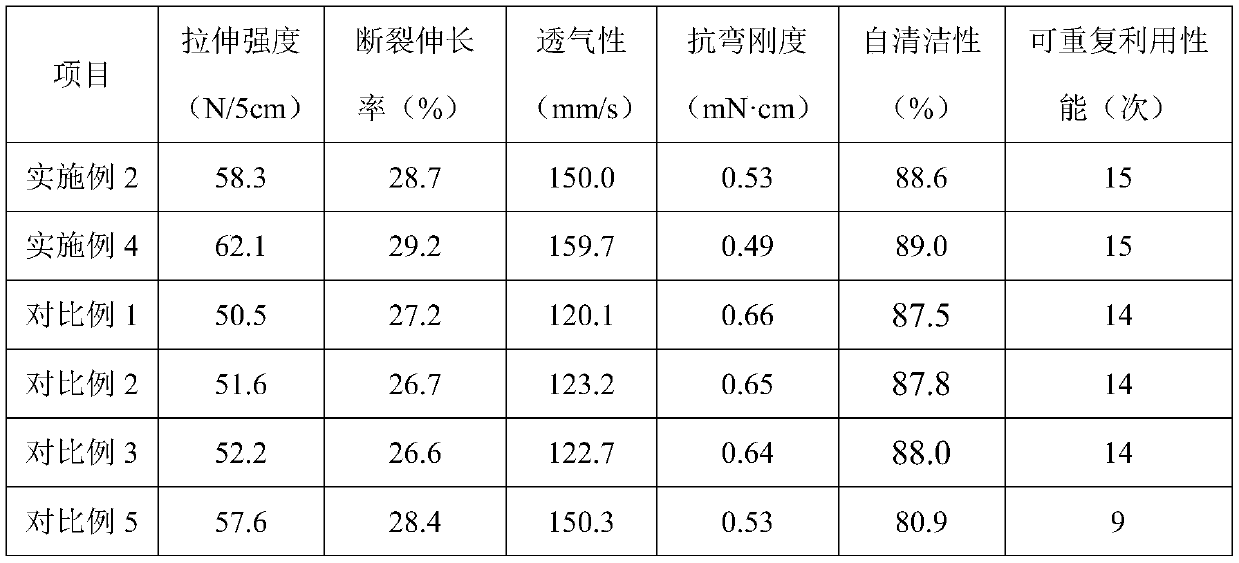

Examples

Embodiment 1

[0021]A preparation method of a multi-functional clothing material. The cotton fiber base is arranged in an aqueous solution of N-methylmorpholine-N-oxide containing nano-antibacterial agents, guanidine phosphate and lithium sulfate for heat treatment. After the end, it is sequentially cured and Self-cleaning finishing, i.e. a multifunctional garment material. After the N-methylmorpholine-N-oxide aqueous solution is first formed into a film shape on the fabric, it is placed in a coagulation bath of pure deionized water. The NMMO molecules on the surface of the film form hydrogen bonds with water molecules, and the two interact with each other. Interdiffusion occurs, the concentration of NMMO solvent in the membrane liquid decreases, the ability to dissolve fibers is lost, and the fiber plastic film is solidified and formed. This phase transformation gradually penetrates into the interior of the fiber membrane, and finally completes the complete transformation to form a membrane...

Embodiment 2

[0028] A preparation method of a multifunctional clothing material, comprising the steps of:

[0029] 1) Preparation of nano-antibacterial agent: add 9mM silver nitrate solution to the chitosan solution with a concentration of 1.6% according to the volume ratio of 1:1.4, stir evenly and add 0.11M silver nitrate solution dropwise to the mixed solution at a speed of 2 drops / second Sodium borohydride, namely nano antibacterial agent;

[0030] 2) The preparation method of the nano self-cleaning agent is: slowly add n-butyl titanate dropwise into the vigorously stirred acetic acid solution, stir until clarified, and then add a betaine solution with a concentration of 3.0%, wherein n-butyl titanate, acetic acid The volume ratio of betaine solution and betaine solution is 1:8:0.04. After mixing evenly, add it dropwise to vigorously stirred deionized water with a pH of 2. The volume ratio of deionized water to the mixed solution is 1.5:1. Stir until it becomes clear, and seal it for 2...

Embodiment 3

[0035] A preparation method of a multifunctional clothing material, comprising the steps of:

[0036] 1) Preparation of nano-antibacterial agent: add 10mM silver nitrate solution to the chitosan solution with a concentration of 1.8% according to the volume ratio of 1:1.5, stir evenly and add 0.12M silver nitrate solution dropwise to the mixed solution at a speed of 3 drops / second Sodium borohydride, namely nano antibacterial agent;

[0037] 2) The preparation method of the nanometer self-cleaning agent is: slowly drop n-butyl titanate into the vigorously stirred acetic acid solution, stir until clarified, and then add a betaine solution with a concentration of 3.5%, wherein n-tetrabutyl titanate, acetic acid The volume ratio of betaine and betaine solution is 1:10:0.05. After mixing evenly, add it dropwise to vigorously stirred deionized water with a pH of 3. The volume ratio of deionized water to the mixed solution is 2:1. Stir until clear, and seal it for 24 hours. Obtain n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com