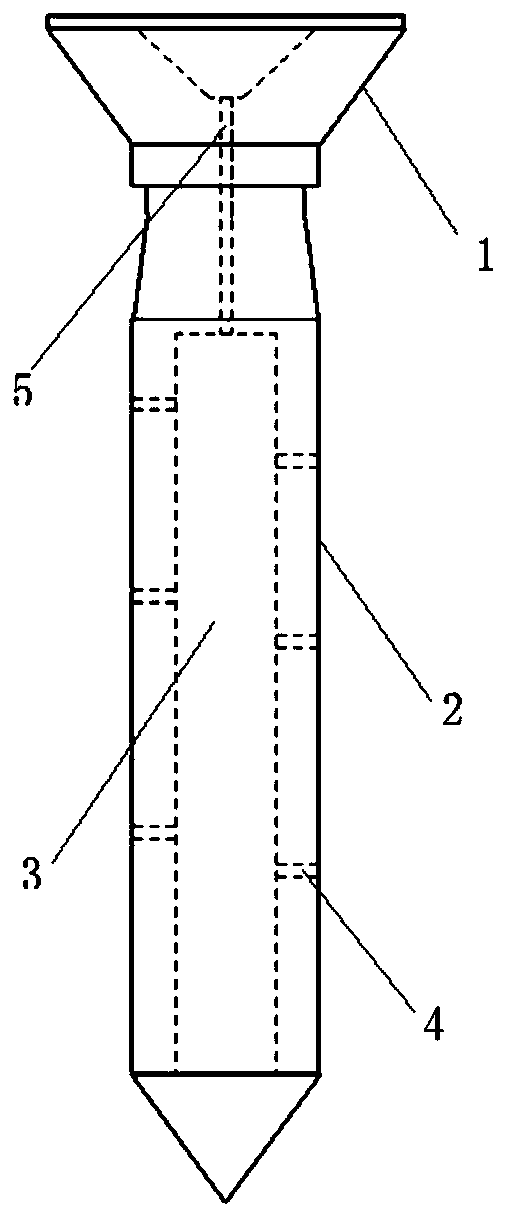

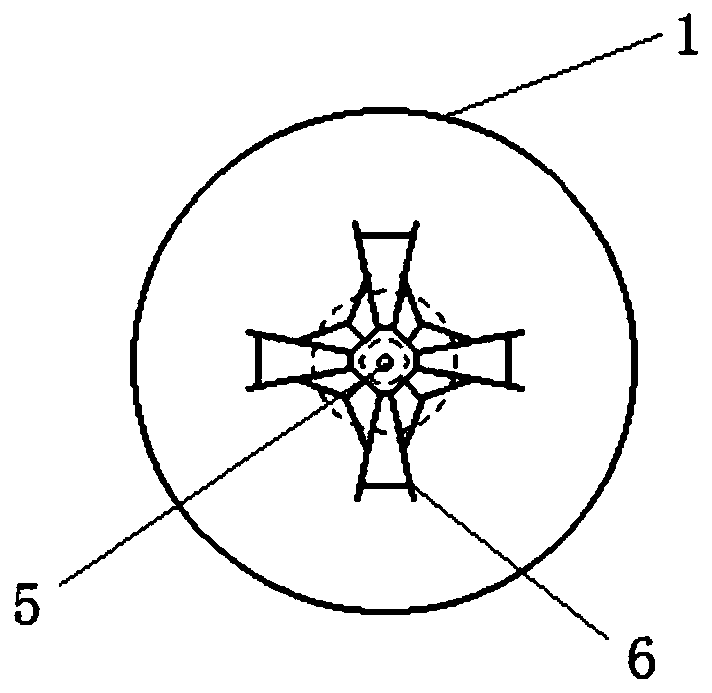

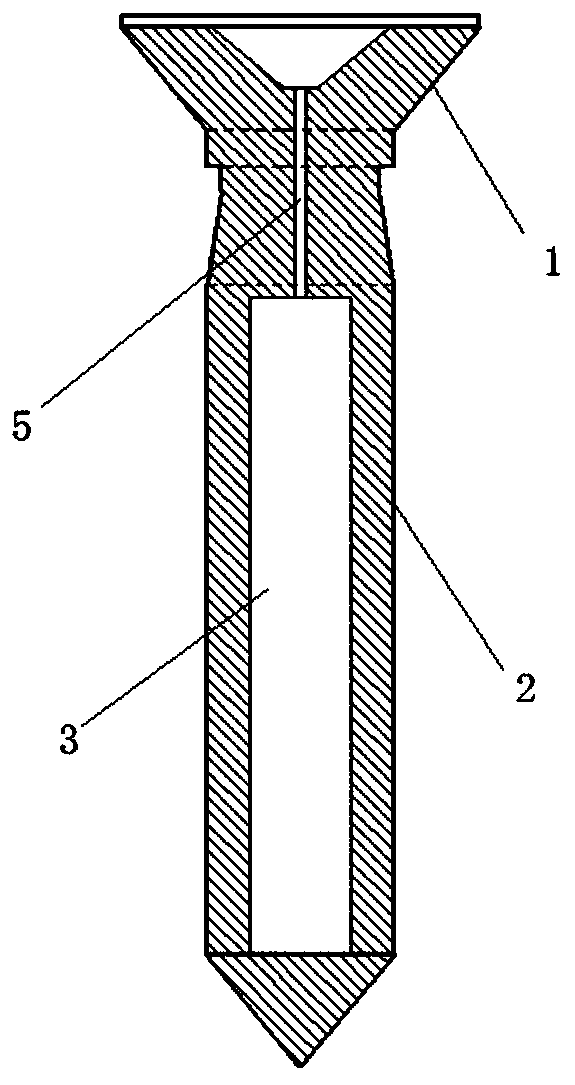

Antibacterial and degradable magnesium alloy nail and manufacturing method thereof

A manufacturing method, magnesium alloy technology, applied in medical science, surgery, etc., can solve problems such as bacterial infection of bone nail implant materials, achieve the effects of reducing the frequency of cell or tissue infection, improving antibacterial properties, and promoting recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An antibacterial and degradable magnesium alloy bone nail. In terms of mass fraction, the bone nail includes the following components: Cu: 0.08%, Ag: 0.08%, Sr: 1.0%, Ta: 0.05%, Ca: 0.4%, The content of a single impurity is less than 0.05%, the total amount of impurities is not more than 0.3%, and the balance is Mg.

[0037] Based on the bone nail of above-mentioned components, its manufacture method step is as follows:

[0038](1) Calculate and prepare the raw materials required for bone nails. The raw materials are high-purity magnesium ingots, high-purity silver wires, high-purity copper wires, Mg-Sr, Mg-Ta, and Mg-Ca master alloys; the mass fraction of magnesium in the high-purity magnesium ingots is ≥99.99% %, the mass fraction of silver in the high-purity silver wire is ≥99.99%, the mass fraction of copper in the high-purity copper wire is ≥99.99%; the mass fraction of Sr in the Mg-Sr master alloy is 10%, and the Ta in the Mg-Ta master alloy The mass fraction of ...

Embodiment 2

[0042] An antibacterial and degradable magnesium alloy bone nail. In terms of mass fraction, the bone nail includes the following components: Cu: 0.1%, Ag: 0.1%, Sr: 1.5%, Ta: 0.06%, Ca: 0.4%, The content of a single impurity is less than 0.05%, the total amount of impurities is not more than 0.3%, and the balance is Mg.

[0043] The manufacturing method of the bone nail based on the above components is the same as in Example 1.

Embodiment 3

[0045] An antibacterial and degradable magnesium alloy bone nail. In terms of mass fraction, the bone nail includes the following components: Cu: 0.2%, Ag: 0.2%, Sr: 2.0%, Ta: 0.07%, Ca: 0.6%, The content of a single impurity is less than 0.05%, the total amount of impurities is not more than 0.3%, and the balance is Mg.

[0046] The manufacturing method of the bone nail based on the above components is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com