Preparation method of polypyrrole quantum dots and sodium-sulfur battery diaphragm

A polypyrrole quantum and sodium-sulfur battery technology, which is applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of aggravated polysulfide ion shuttle, high working temperature, material fatigue damage, etc., to increase polysulfide adsorption ability, improved safety and reliability, and the effect of high heat-resistant temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

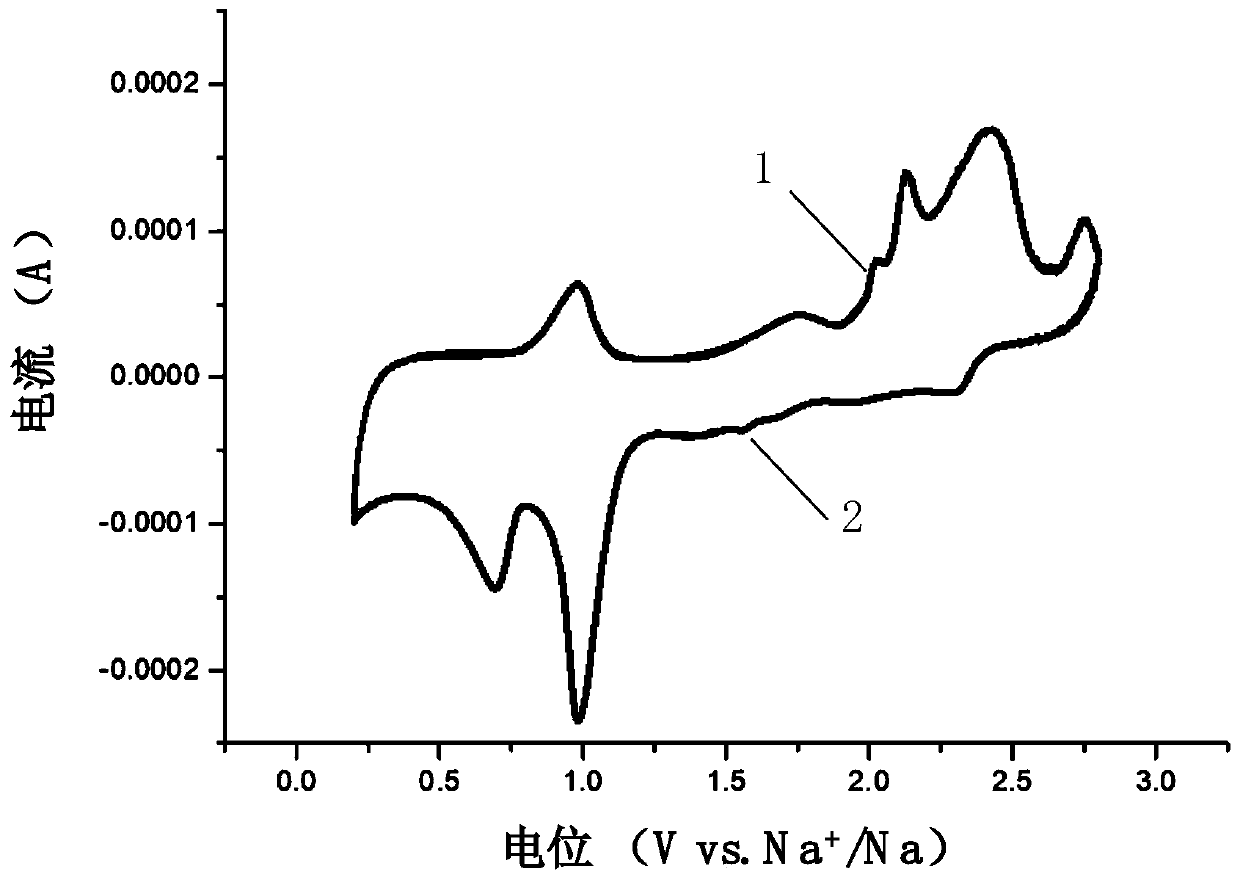

Image

Examples

Embodiment 1

[0040] The DMSO solution preparation of embodiment 1 pyrroles

[0041] 0.15 g of pyrrole was dissolved in 50 mL of DMSO, dispersed by ultrasonic vibration (ultrasonic frequency 40 kHz) for 5 minutes to obtain a pyrrole solution.

Embodiment 2

[0042] The DMSO solution preparation of embodiment 2 ferric nitrate

[0043] Take 40mL DMSO to dissolve 0.2g Fe(NO 3 ) 3 , add 2g sodium dodecylbenzene sulfonate, ultrasonic vibration (ultrasonic frequency 40kHz) disperses for 5 minutes and obtain the mixed solution containing ferric nitrate (abbreviation ferric nitrate solution, hereinafter the same).

Embodiment 3

[0044] The DMSO solution preparation of embodiment 3 polypyrrole quantum dots

[0045] 0.5 g of pyrrole was dissolved in 50 mL of DMSO, dispersed by ultrasonic vibration (ultrasonic frequency 40 kHz) for 5 minutes to obtain a pyrrole solution. Take 40mL DMSO to dissolve 1g Fe(NO 3 ) 3 , adding 2g of sodium dodecylbenzenesulfonate, ultrasonic vibration (ultrasonic frequency 40kHz) dispersed for 5 minutes to obtain ferric nitrate solution.

[0046] In a solvothermal reaction kettle with a volume of 100mL, after stirring and mixing the above pyrrole solution and ferric nitrate solution evenly, the DMSO solution of polypyrrole quantum dots was obtained by solvothermal reaction at 180°C for 0.5h and cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com