Composite temporary plugging agent for fracturing and preparation method of composite temporary plugging agent for fracturing

A temporary plugging agent and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance of temporary plugging agents, high content of unbroken gel, and difficulty in reservoir cracks, etc. Achieve the effects of increasing reservoir productivity, efficient temporary plugging and degradation, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

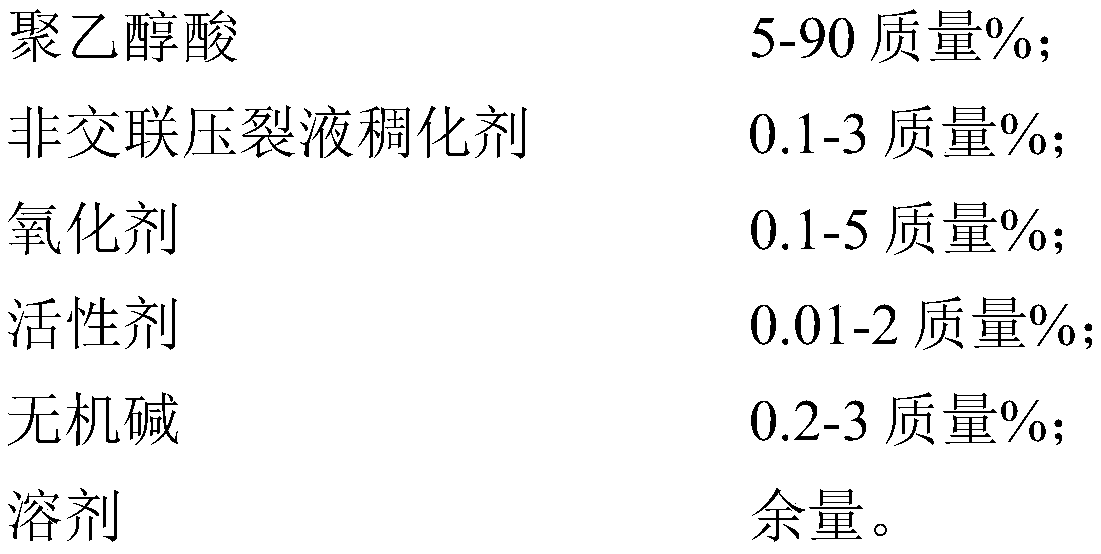

[0065] In this embodiment, based on the total mass of the composite temporary plugging agent, the composite temporary plugging agent includes the following components:

[0066]

[0067]

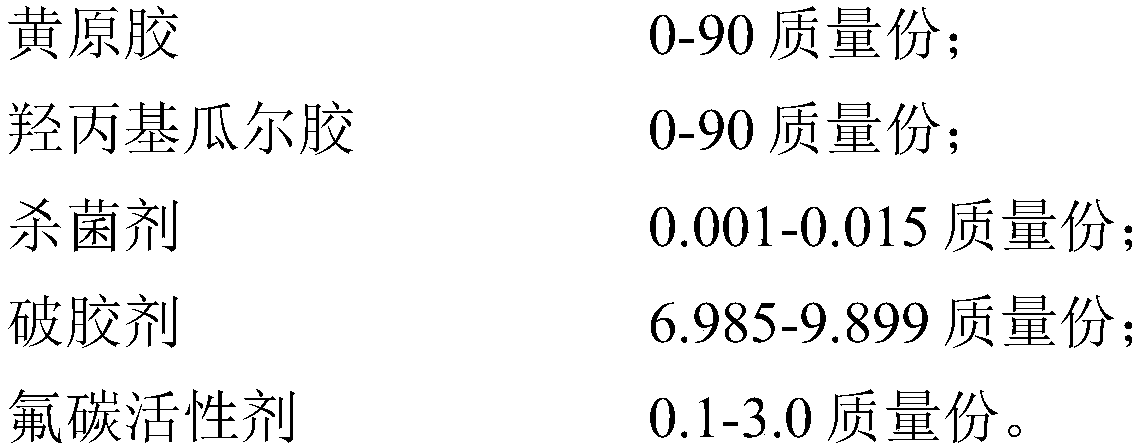

[0068] Wherein, the non-crosslinked fracturing fluid thickener comprises the following components (based on the total mass of the non-crosslinked fracturing fluid thickener):

[0069]

[0070] Wherein, the active agent is FC-911 fluorocarbon active agent.

[0071] Mix reducing gum and hydroxypropyl guar gum according to the above fracturing fluid thickener formula to obtain mixture 1, mix paraformaldehyde and potassium persulfate to obtain mixture 2, and then mix mixture 1 and 2 with FC-95 fluorocarbon active Mix the agent and stir evenly to obtain a fracturing fluid thickener.

[0072] Then, according to the formula ratio of the temporary plugging agent, mix polyglycolic acid, fracturing fluid thickener, potassium persulfate, active agent and sodium carbonate evenly, add water, and...

Embodiment 2

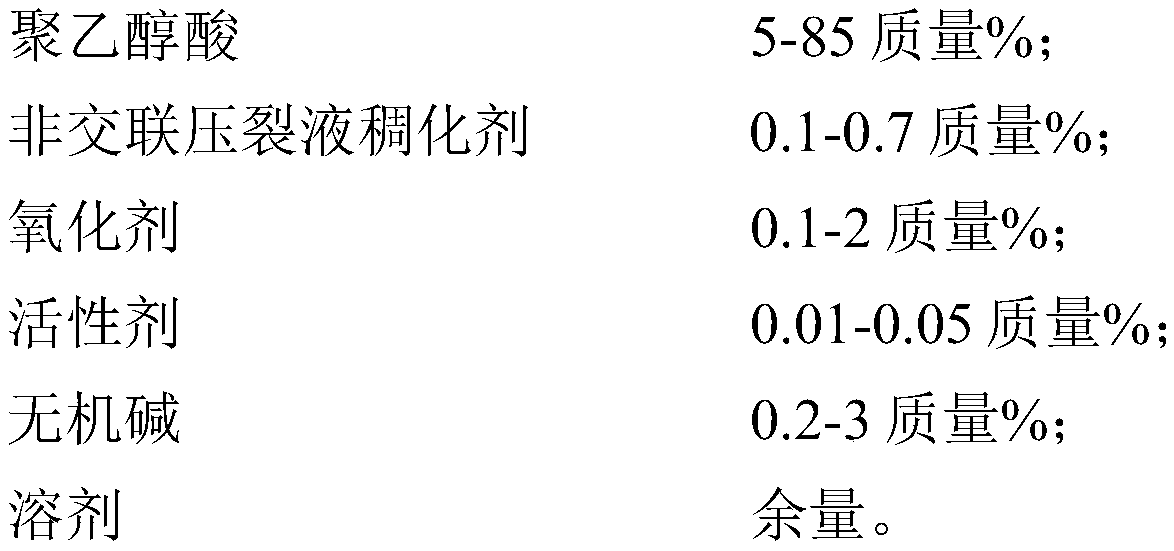

[0074] In this embodiment, based on the total mass of the composite temporary plugging agent, the composite temporary plugging agent includes the following components:

[0075]

[0076] Wherein, the non-crosslinked fracturing fluid thickener comprises the following components (based on the total mass of the non-crosslinked fracturing fluid thickener):

[0077]

[0078]

[0079] Among them, the activating agent is FC-911 fluorocarbon activating agent and FC-95 fluorocarbon activating agent. Based on the total mass of the composite temporary plugging agent, FC-911 fluorocarbon activating agent is 0.2 parts by mass, and FC-95 fluorocarbon activating agent is 0.2 parts by mass. The dose is 1 part by mass.

[0080] Mix reducing gum and hydroxypropyl guar gum according to the above fracturing fluid thickener formula to obtain mixture 1, mix paraformaldehyde and potassium persulfate to obtain mixture 2, and then mix mixture 1 and 2 with FC-95 fluorocarbon active Mix the age...

Embodiment 3

[0083] In this embodiment, based on the total mass of the composite temporary plugging agent, the composite temporary plugging agent includes the following components:

[0084]

[0085] Wherein, the non-crosslinked fracturing fluid thickener comprises the following components (based on the total mass of the non-crosslinked fracturing fluid thickener):

[0086]

[0087] Among them, the activating agent is FC-911 fluorocarbon activating agent and FC-95 fluorocarbon activating agent, based on the total mass of the composite temporary plugging agent, the FC-911 fluorocarbon activating agent is 0.02 parts by mass, and the FC-95 fluorocarbon activating agent is 0.02 parts by mass. The dose is 0.03 parts by mass.

[0088] Mix reducing gum and hydroxypropyl guar gum according to the above fracturing fluid thickener formula to obtain mixture 1, mix paraformaldehyde and potassium persulfate to obtain mixture 2, and then mix mixture 1 and 2 with FC-95 fluorocarbon active Mix the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com