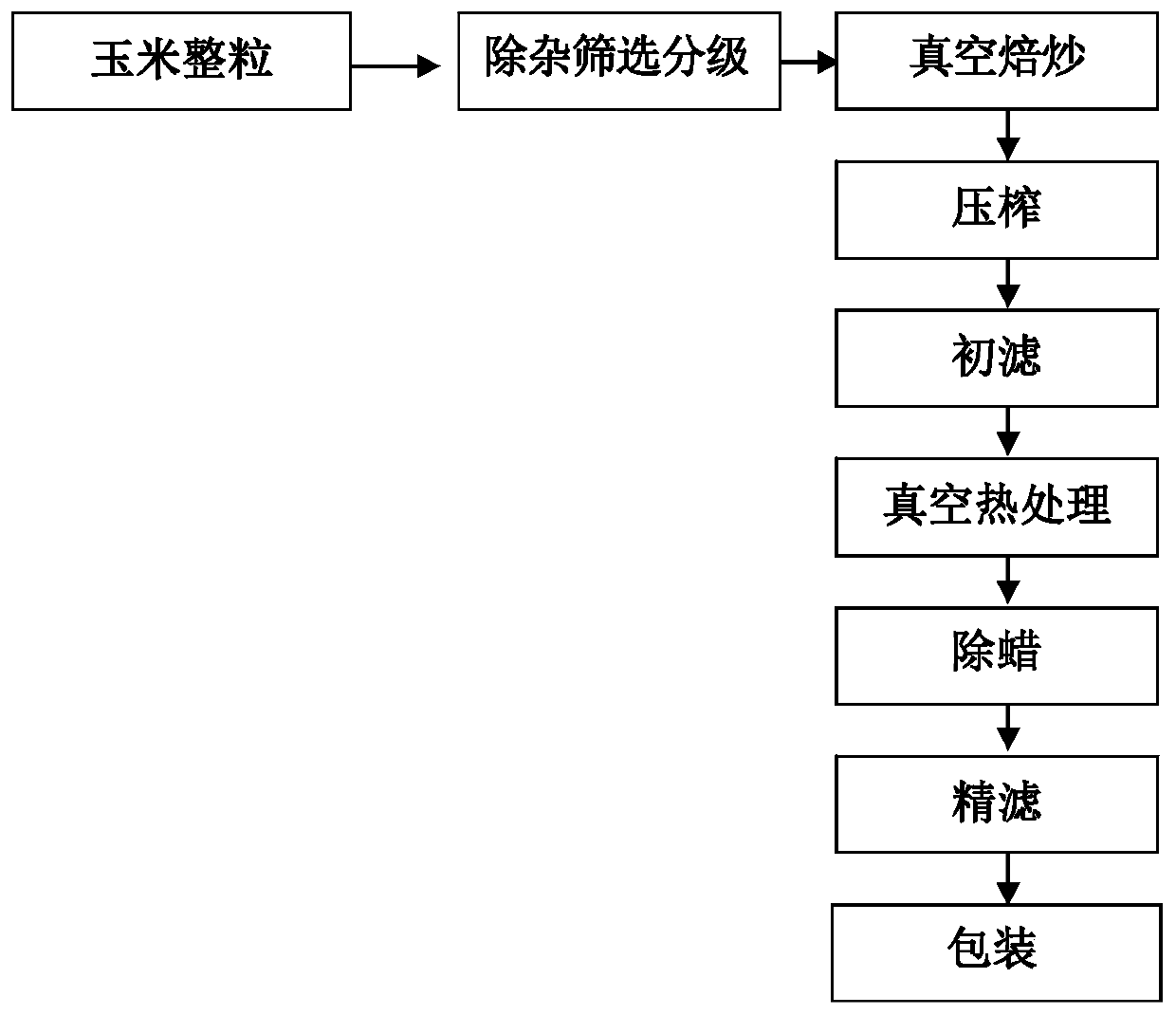

Method for preparing corn oil from corn kernels

A corn oil and corn kernel technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, can solve the problem of increasing equipment investment cost, production cost and energy consumption, and the mastery of production technology affects the quality of corn oil and cannot be obtained. High-quality corn oil and other problems, to achieve the effect of omitting the embryo extraction process, solving the loss of oil content, and solving the problem of excessive storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The impurity-removed and screened plump whole corn kernels were roasted at a temperature of 75°C and a vacuum of -0.07MPa for 0.3h, then the temperature was controlled at 75°C and kept for 0.5h, and the moisture content of the whole corn kernels was 6%; vacuum roasting The fried whole corn kernels are squeezed under the conditions of the temperature of 75°C and the pressure of 30MPa; the squeezed oil juice is separated from the oil residue with a 200-mesh stainless steel screen, and the separated corn grits and corn kernels are separated by 1 : 10 mixed and then squeezed, the separated oil is heated to 70°C at a stirring speed of 60r / min, the vacuum degree is kept at -0.07MPa, and the heat is kept for 0.2h; the corn oil after vacuum heat treatment is cooled to 3°C, kept 2h, then carry out precision filtration with a 600-mesh filter cloth to obtain a corn oil product. The main technical indicators of the corn oil obtained are as follows:

[0032] Color: Y=28, R=4.7; aci...

Embodiment 2

[0034] The impurity-removed and screened plump whole corn kernels were roasted at a temperature of 70°C and a vacuum of -0.09MPa for 0.8h, then controlled at 75°C for 0.5h, and the moisture content of the whole corn kernels was 4%; vacuum roasting The fried whole corn kernels are squeezed under the conditions of the temperature of 65°C and the pressure of 50MPa; the squeezed oil juice is separated from the oil residue with a 100-mesh stainless steel screen, and the separated corn grits and corn kernels are separated by 1 : 5 and then squeezed, the separated oil was heated to 60°C at a stirring speed of 30r / min, the vacuum degree was kept at -0.09MPa, and kept for 0.4h; the corn oil after vacuum heat treatment was cooled to 2°C, kept 3h, and then finely filtered with a 600-mesh filter cloth to obtain a corn oil product. The main technical indicators of the corn oil obtained are as follows:

[0035] Color: Y=28, R=4.7; acid value (KOH, mg / g): 2.3; peroxide value (mg / kg): 4.2; a...

Embodiment 3

[0037] The impurity-removed and screened plump whole corn kernels were roasted at a temperature of 65°C and a vacuum of -0.07MPa for 0.3h, and then the temperature was controlled at 75°C and kept for 0.5h. The moisture content of the whole corn kernels was 7%; vacuum roasting The fried whole corn kernels are squeezed under the conditions of the temperature of 75°C and the pressure of 30MPa; the squeezed oil juice is separated from the oil residue with a 200-mesh stainless steel screen, and the separated corn grits and corn kernels are separated by 1 : 10 mixed and then squeezed, the separated oil was heated to 64°C at a stirring speed of 60r / min, the vacuum degree was kept at -0.07MPa, and kept for 0.2h; the corn oil after vacuum heat treatment was cooled to 3°C, kept 2h, then carry out precision filtration with a 600-mesh filter cloth to obtain a corn oil product. The main technical indicators of the corn oil obtained are as follows:

[0038] Color: Y=28, R=4.7; acid value (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com