a kind of nico 2 the s 4 Preparation method of carbon airgel composite electrode material

A composite electrode and carbon aerogel technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of expensive raw materials and complicated composite materials technology, and achieve the effects of simple technology, slow down structure collapse, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Make the prepared watermelon rind (remove the watermelon pulp and green skin) into a size of 10*20*30mm 3 block, and its surface was cleaned with absolute ethanol; 9mmol Ni(NO 3 ) 2 ·6H 2 O and 18mmol Co(NO 3 ) 2 ·6H 2 O is dissolved in a mixed solution of 30ml ethylene glycol and 10ml ultrapure water, configured to contain Ni 2+ and Co 2+ The mixed solution with a molar ratio of 1:2 was stirred at a stirring speed of 30r / min for 1h, then 36mmol of thiourea was added, and stirred at the same speed for 1h to obtain a uniformly mixed precursor solution; the configured precursor solution and block Put the watermelon rind into a 100ml reactor, conduct a hydrothermal reaction at 180°C for 12 hours, freeze-dry the product at -70°C, and heat the dried sample to 400°C at a heating rate of 5°C / min in a nitrogen atmosphere Insulate for 2 hours, cool to room temperature, and the final product is NiCo 2 S 4 / Carbon airgel composites.

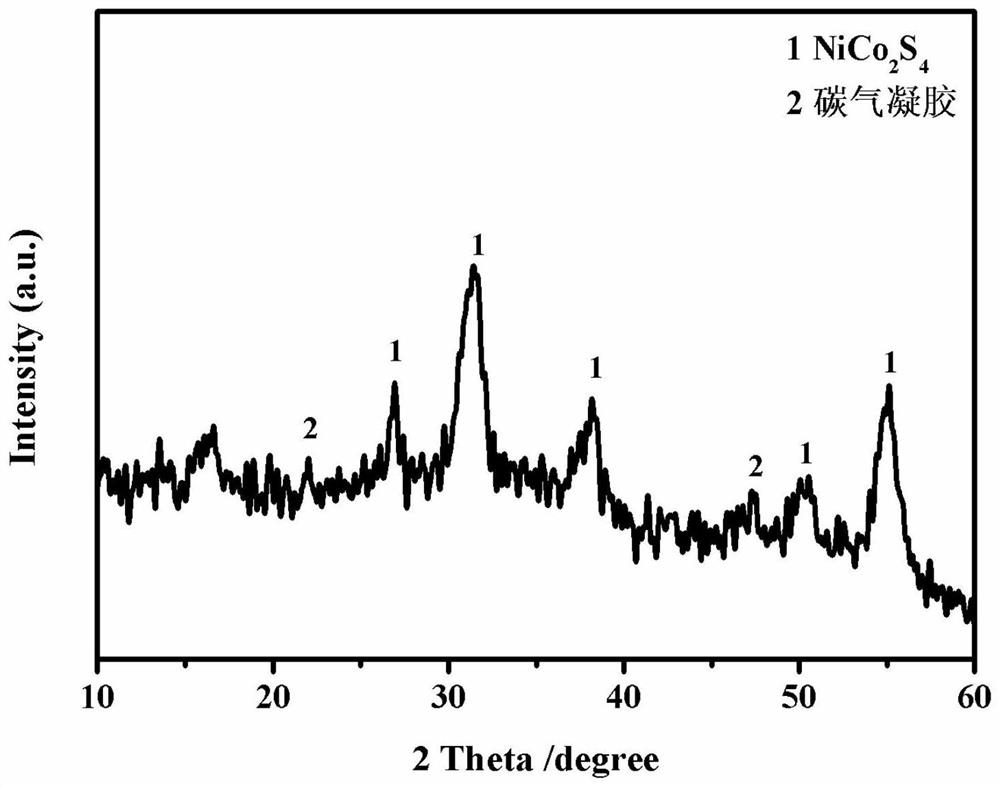

[0024] Its XRD spectrum is shown in...

Embodiment 2

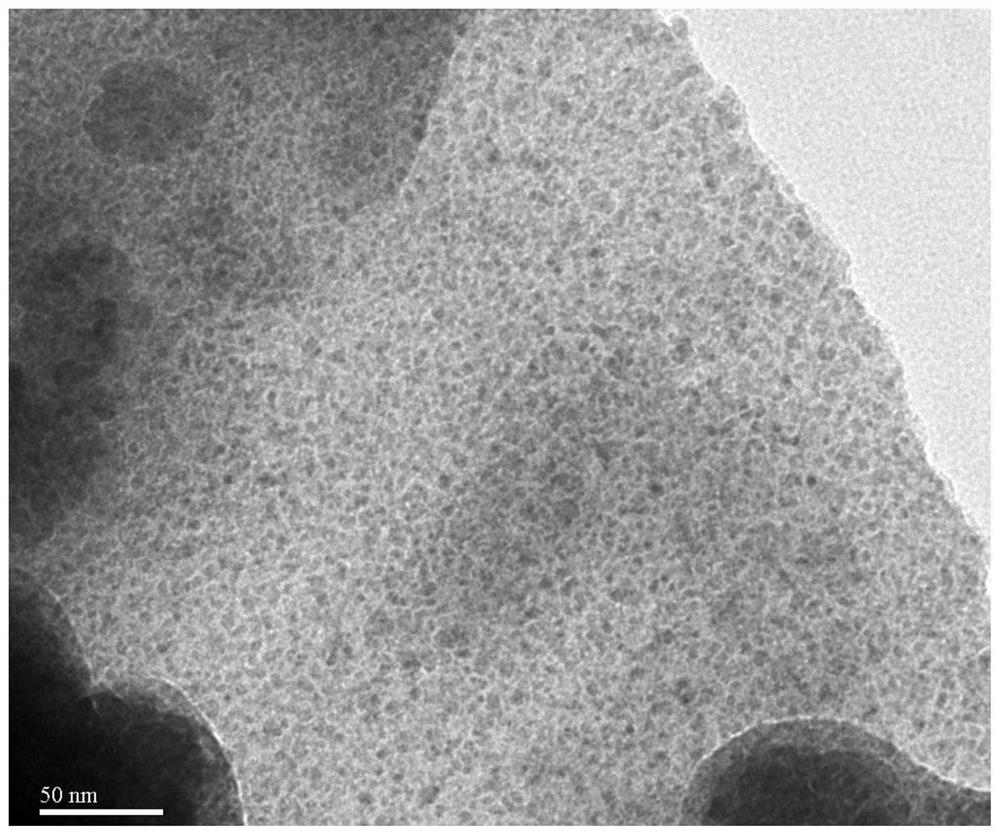

[0026] Make the prepared watermelon rind into a size of 10*20*30mm 3 block, and its surface was cleaned with absolute ethanol; 16mmol Ni(NO 3 ) 2 ·6H 2 O and 32mmol Co(NO 3 ) 2 ·6H 2 O is dissolved in a mixed solution of 35ml ethylene glycol and 10ml ultrapure water, configured to contain Ni 2+ and Co 2+ The mixed solution with a molar ratio of 1:2 was stirred at a stirring speed of 40r / min for 2h, then 64mmol of thiourea was added, and then stirred at the same speed for 2h to obtain a uniformly mixed precursor solution; the configured precursor solution and block Put the watermelon rind into a 100ml reactor, conduct a hydrothermal reaction at 160°C for 14 hours, freeze-dry the product at -70°C, and heat the dried sample to 450°C at a heating rate of 3°C / min in a nitrogen atmosphere Keep warm for 2h. Cool to room temperature, the final product is NiCo 2 S 4 / Carbon airgel composites. Its TEM image is shown in Figure 5 , confirmed that the prepared NiCo 2 S 4 Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com