Special environment-friendly cultivation medium for Rhododendron and its preparation method

A technology of cultivation substrate and preparation method, applied in the directions of culture medium, planting substrate, botanical equipment and methods, etc., can solve problems such as wetland environment destruction, and achieve the effects of prolonging fertilizer efficiency, reducing cost and promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

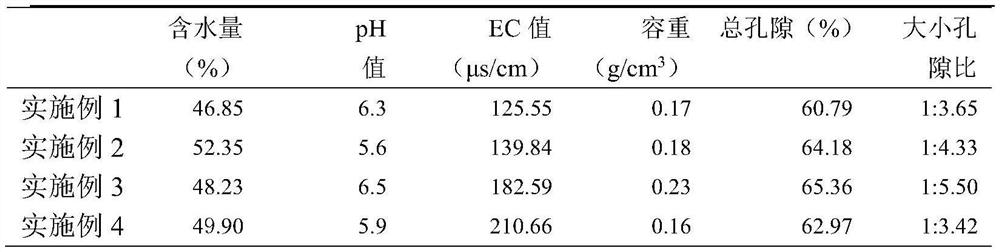

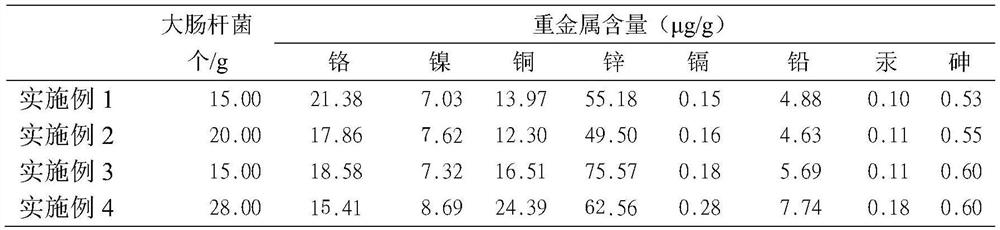

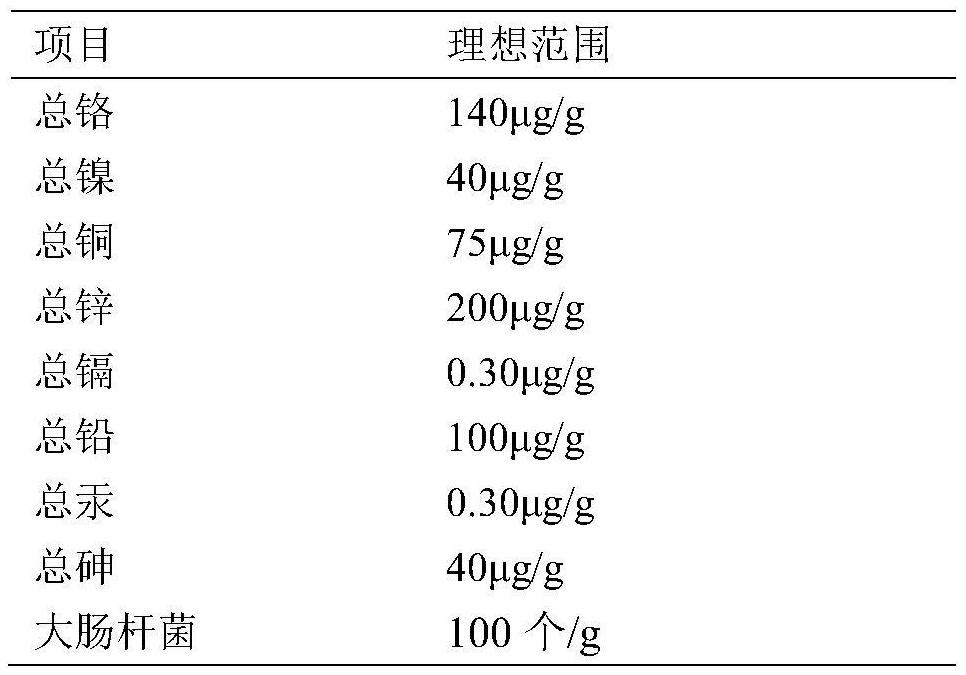

Examples

Embodiment 1

[0026] (1), 4 parts of peat, 4 parts of mushroom mud, 5 parts of rice bran and 3 parts of wheat straw are mixed and naturally retting for 30 days;

[0027] (2) Take 4 portions of cornstarch residue and pour them into the fermentation tank, add the same weight of hot water at about 60°C and mix well, wait until the temperature is naturally cooled to 32±2°C, stir properly during this period to prevent precipitation, and then sprinkle the yeast evenly Stir the yeast evenly, add 133.33g per 100kg of cornstarch residue, control the temperature between 28-36°C, stir twice a day for the first 3 days after adding the yeast, and sprinkle acetic acid bacteria after 7 days of anaerobic fermentation. The amount of acetic acid bacteria added is 6.67g per hundred kilograms of cornstarch residue, stirred evenly, and reacted for 10 days under anaerobic conditions;

[0028] (3), mix the products of steps (1) and (2), add Bacillus subtilis and crude fiber degrading bacteria, react at 45-60°C fo...

Embodiment 2

[0033] (1), 10 parts of peat, 8 parts of mushroom mud, 5 parts of rice bran and 3 parts of wheat straw are mixed and naturally retting for 15 days;

[0034] (2) Take 8 portions of cornstarch residue and pour them into the fermentation tank, add the same weight of hot water at about 60°C and mix well, wait until the temperature is naturally cooled to 32±2°C, stir properly during this period to prevent precipitation, and then sprinkle the yeast evenly Stir evenly, add 133.33g per 100kg of cornstarch residue, control the temperature at 28-36°C, stir twice a day for the first 3 days after adding yeast, after 15 days of anaerobic fermentation, sprinkle acetic acid bacteria, add acetic acid bacteria The amount is 6.67g per 100 kilograms of corn starch slag, stirred evenly, and reacted for 15 days under anaerobic conditions;

[0035] (3), mix the products of steps (1) and (2), add Bacillus subtilis and crude fiber degrading bacteria, react under aerobic conditions at 45-60°C for 20 d...

Embodiment 3

[0040] (1), 6 parts of peat, 10 parts of mushroom mud, 3 parts of rice bran and 1 part of wheat straw are mixed and naturally retting for 15 days;

[0041] (2) Take 4 portions of cornstarch residue and pour them into the fermentation tank, add the same weight of hot water at about 70°C and mix well, wait until the temperature is naturally cooled to 32±2°C, stir properly during this period to prevent precipitation, and then sprinkle the yeast evenly Stir evenly, add 133.33g per 100kg of cornstarch residue, control the temperature at 28-36°C, stir twice a day for the first 3 days after adding yeast, after 12 days of anaerobic fermentation, sprinkle acetic acid bacteria, add acetic acid bacteria The amount is 6.67g per 100 kilograms of cornstarch slag, stirred evenly, and reacted for 13 days under anaerobic conditions;

[0042] (3), mix the products of steps (1) and (2), add Bacillus subtilis and crude fiber degrading bacteria, react under aerobic conditions at 45-60°C for 17 day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com