A kind of organic waste gas adsorbent and its preparation method, organic waste gas treatment method

A technology of organic waste gas and treatment methods, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of adsorbent structure damage, small saturated adsorption capacity, difficult to adsorb CO, etc., and achieve enhanced hydrothermal stability, Increase the adsorption capacity and enhance the effect of adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The preparation of embodiment 1 metal organic framework compound adsorbent

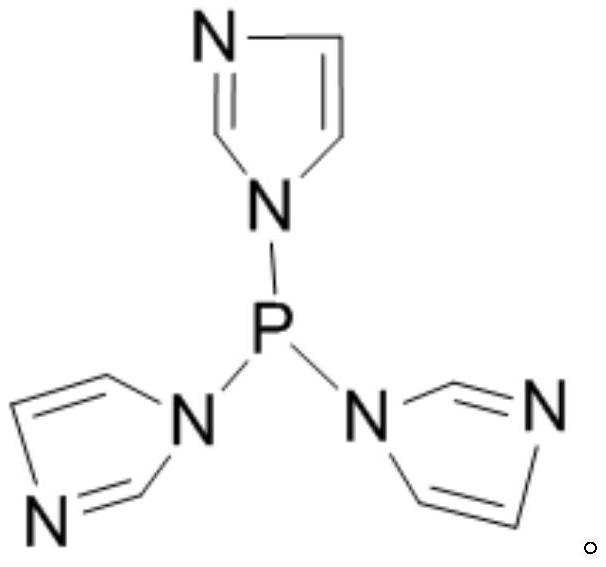

[0053] a) Preparation of Adsorbent A

[0054] 2gCr(NO 3 ) 3 9H 2 O, 0.099gCuCl, 0.027gLa(NO 3 ) 3 ·6H 2 O, 5.73g 2,2'-diquinoline-4,4'-dicarboxylic acid, 1.165g ligand 2a Put 200g of distilled water in a beaker, stir at 70°C for 90min, mix well, titrate with 1mol / L hydrochloric acid to pH = 3, then transfer to a polytetrafluoroethylene-lined stainless steel reactor, react at 180°C for 60h, and cool naturally to At room temperature, filter, wash, and dry to obtain silver-gray crystals, which are then processed into spherical particles with a diameter of 0.1 mm to 0.2 mm to obtain about 5 g of adsorbent A.

[0055] b) Preparation of Adsorbent B

[0056] 1.16gCo(NO 3 ) 2 ·6H 2 O, 0.099gCuCl, 0.026gLa(NO 3 ) 3 ·6H 2 O, 6.1g of 2,2'-diquinoline-4,4'-dicarboxylic acid, 1.553g of ligand 2a, and 200g of distilled water were placed in a beaker, stirred at 70°C for 90min, mixed evenly, and...

Embodiment 2

[0073] Embodiment 2 adsorption effect experiment

[0074] (1) Experimental equipment

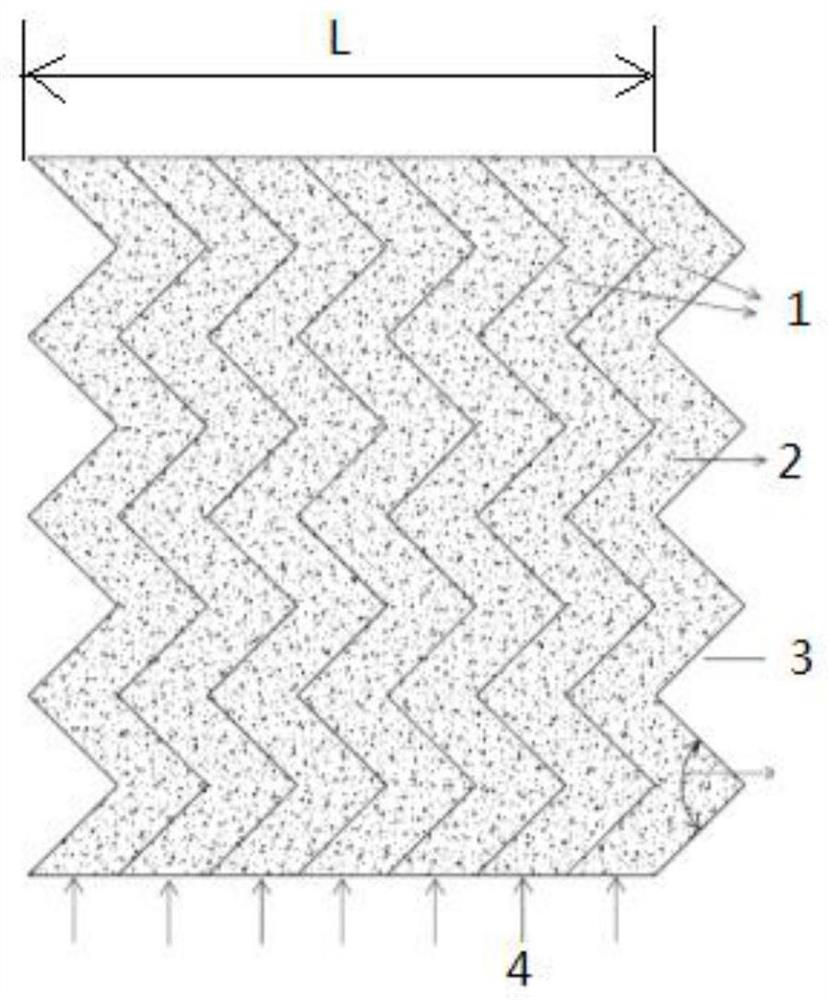

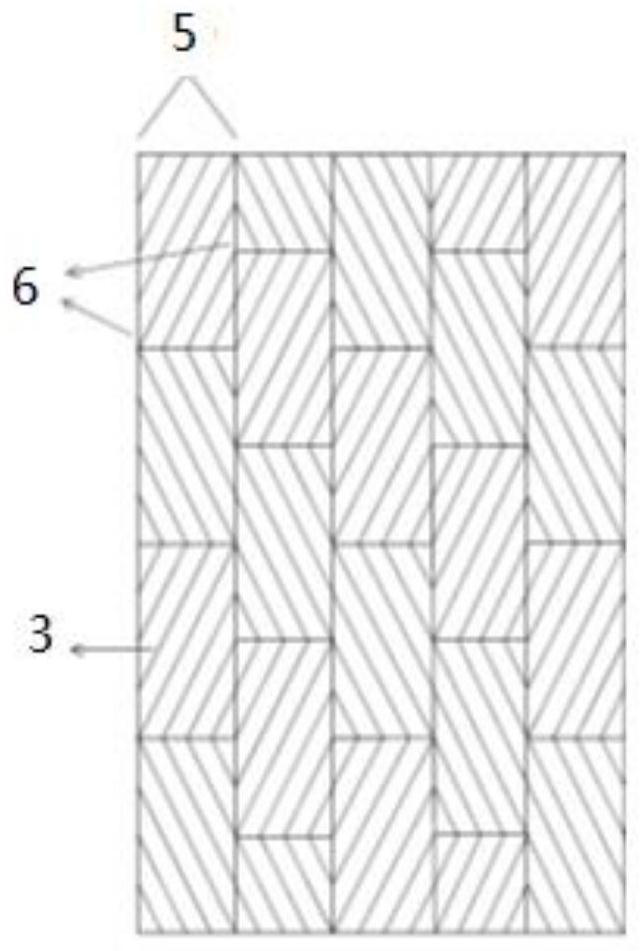

[0075] Self-made experimental adsorption equipment, refer to figure 1 , figure 2As shown, the adsorption device has a plurality of sheets 5 and a plurality of baffle microchannels 1 , and the baffle microchannels 1 are separated by a plurality of zigzag baffles 3 arranged in parallel and alternately. The zigzag baffles 3 have a bending angle of 100°, the width of the formed microchannel 1 is 0.1 cm, the length of the baffles 3 is 5 cm, the spacing between the lamella partitions 6 is 0.2 cm, and the length of each lamella is 5 cm. 5 sheets, the microchannel is filled with 7g of adsorbent prepared according to the method of the examples.

[0076] (2) Taking the tail gas from the reaction of isononanal (3,5,5-trimethylhexanal) to prepare isononanoic acid (3,5,5-trimethylhexanoic acid) as an example to verify the adsorption effect, the temperature of the tail gas is At 40°C, the gas composi...

Embodiment 3

[0105] Embodiment 3 desorption effect experiment

[0106] After the above-mentioned adsorbent is adsorbed and saturated, it is purged with hot oxygen-poor air (5% oxygen content) at 180°C, and the flow rate of the purge gas is 8L / h.

[0107] Adsorbent A:

[0108]

[0109] Note: "-"—not detected

[0110] Adsorbent B:

[0111]

[0112] Note: "-"—not detected

[0113] Adsorbent C:

[0114]

[0115] Note: "-"—not detected

[0116] Adsorbent D:

[0117]

[0118] Note: "-"—not detected

[0119] Adsorbent E:

[0120]

[0121] Note: "-"—not detected

[0122] Adsorbent F:

[0123]

[0124] Note: "-"—not detected

[0125] Adsorbent G:

[0126]

[0127] Note: "-"—not detected

[0128] Adsorbent H:

[0129]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com