Remaining needle hose, hose extrusion system and hose extrusion process

An extrusion process and indwelling needle technology, applied in the direction of needles, instruments introduced into the body, etc., can solve the problems of easy rupture of the hose and flow into the blood vessel, easy breakage and blockage of the hose, poor biocompatibility, etc. Low extrusion accuracy and good histocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0063] The first specific embodiment of the present invention provides an indwelling needle hose, which is made of TPU material. TPU, the English name is Thermoplastic polyurethanes, and the Chinese name is thermoplastic polyurethane elastomer rubber.

[0064] The indwelling needle hose made of TPU material provided by the first specific embodiment of the present invention can not only effectively avoid the clinical manifestations of FEP indwelling needles in the prior art, which easily lead to the occurrence of phlebitis, easy to form thrombus, poor biocompatibility, The hose is easy to fold and block the tube, and the hose is easy to break and flow into the blood vessel. Moreover, it has the following advantages in clinical application:

[0065] (1) The material is soft and has good tissue compatibility;

[0066] (2) It can effectively reduce the incidence of phlebitis, making it safer and more comfortable to use;

[0067] (3) It has excellent softening function, which can...

no. 2 Embodiment

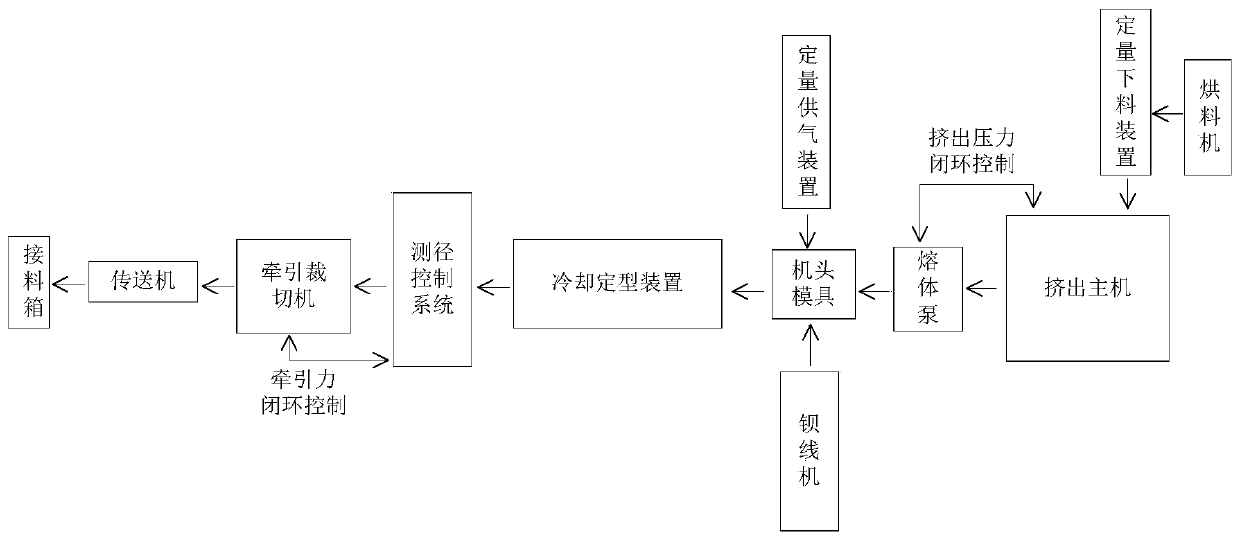

[0073] see figure 1 , figure 1 Schematic diagram of the structure of the hose extruding system provided for the second specific embodiment of the present invention.

[0074] The second embodiment of the present invention provides a hose extrusion system, which is used to make the indwelling needle hose made of TPU as provided in the first embodiment of the present invention.

[0075] The hose extrusion system provided by the second specific embodiment of the present invention includes an extrusion host, a melt pump, a head mold, a cooling and setting device, a diameter measurement control system, and a traction and cutting machine. in:

[0076] The extruder is a material processing and molding equipment, which is used to process TPU pellets into rubber (that is, TPU plastic melt), and extrude the rubber into the melt pump. Specifically, the extrusion host can use 30 #extrude host;

[0077] The melt pump, that is, the melt pressure gear pump, is used to control the extrusio...

no. 3 Embodiment

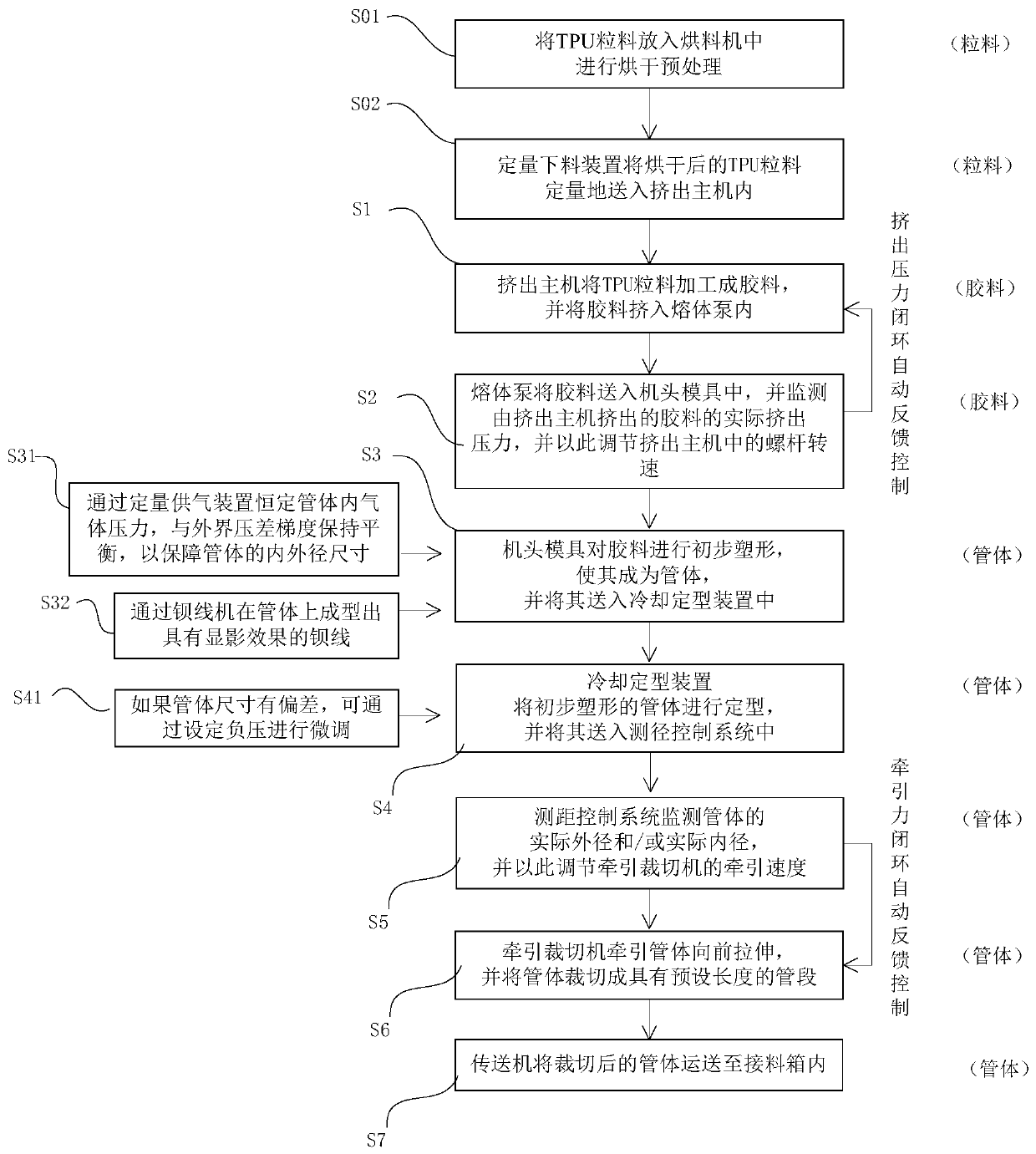

[0105] see figure 2 , figure 2 The flow chart of the hose extrusion process provided by the third specific embodiment of the present invention.

[0106] The third embodiment of the present invention provides a hose extrusion process, which can be applied to make the indwelling needle hose made of TPU as provided in the first embodiment above.

[0107] The hose extrusion process provided by the third specific embodiment of the present invention includes the following steps:

[0108] Step S1: The extruder host processes the TPU pellets into rubber, and squeezes the rubber into the melt pump;

[0109] Step S2: The melt pump sends the rubber material into the head mold, and monitors the actual extrusion pressure of the rubber material extruded by the extrusion host through the extrusion pressure closed-loop automatic feedback control system, and adjusts the extrusion according to the actual extrusion pressure The screw speed of the main engine;

[0110] Step S3: The head mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com