Synergistic processing device and method of ship waste gas washing waste liquid and ship sanitary sewage

A domestic sewage and exhaust gas washing technology, which is applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as increased operating costs, prevent secondary pollution, save ship space and Operating cost, effect of solving carbon source shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

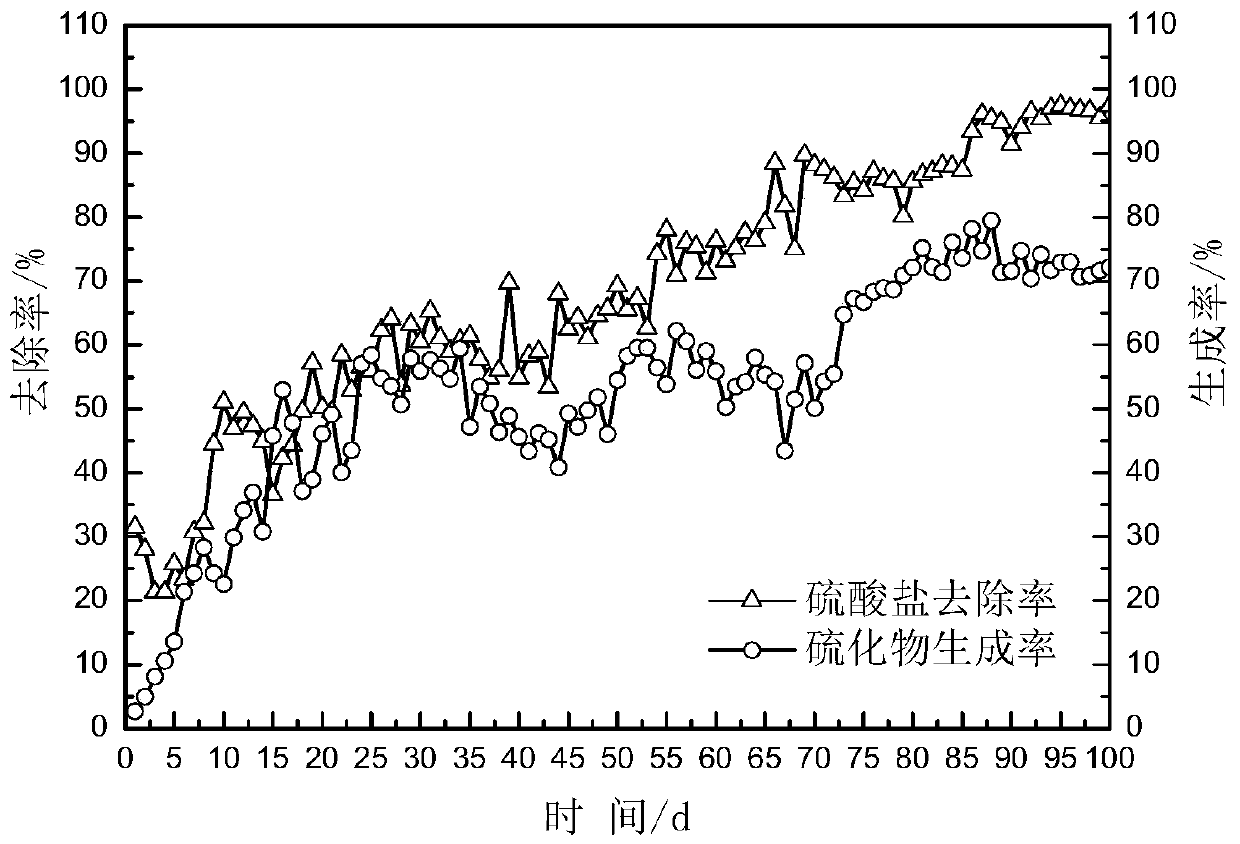

Embodiment 1

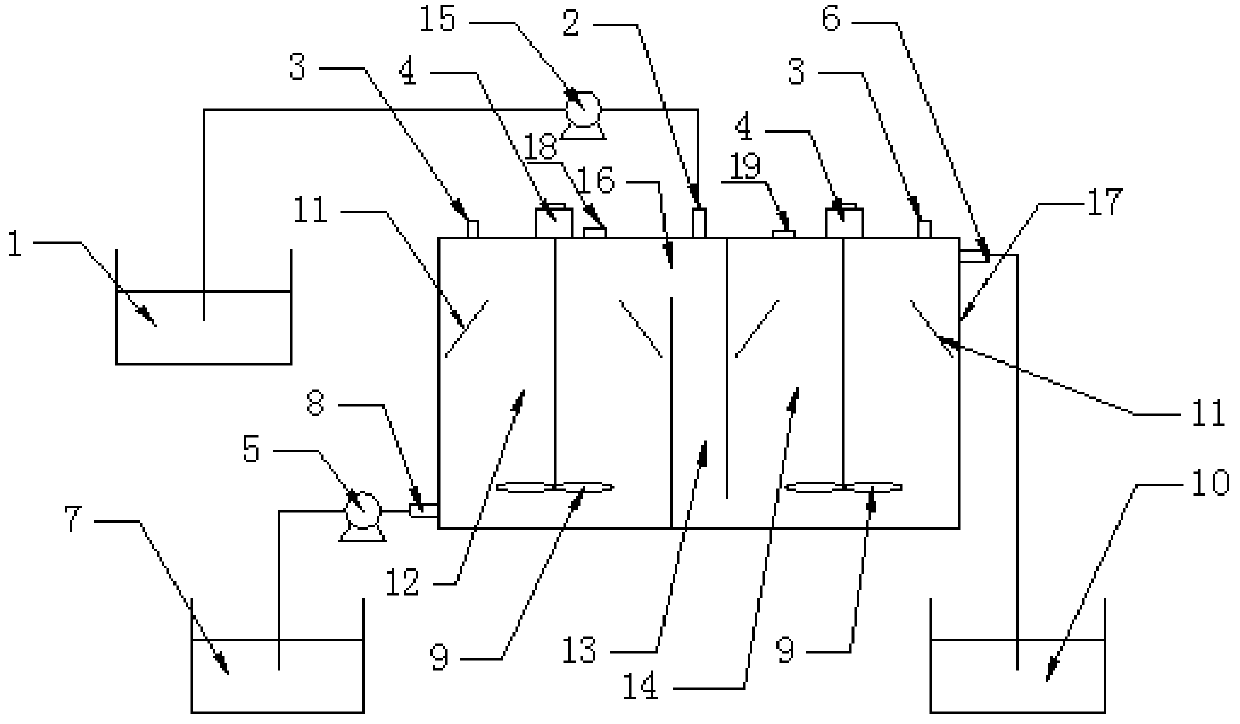

[0047] This embodiment provides a device and method for co-processing ship exhaust gas washing waste liquid and ship domestic sewage. The co-processing device includes a reactor shell 17, which is provided with a liquid inlet I8, a liquid inlet II2 and a liquid outlet 6, and the reactor shell 17 is provided with a heterotrophic reaction zone 12 connected in sequence. , the buffer zone 13 and the autotrophic reaction zone 14, the volume of the heterotrophic reaction zone 12 and the autotrophic reaction zone 14 is the same, the overflow port 16 is provided with the buffer zone 13 on the top of the heterotrophic reaction zone 12 and communicates with the buffer zone 13, and the overflow port 16 is vertical The height is 1.5cm, the lower part of the buffer zone 13 communicates with the autotrophic reaction zone 14, and the upper ends of the heterotrophic reaction zone 12 and the autotrophic reaction zone 14 are all provided with vent holes 3; The liquid port II2 is connected with ...

Embodiment 2

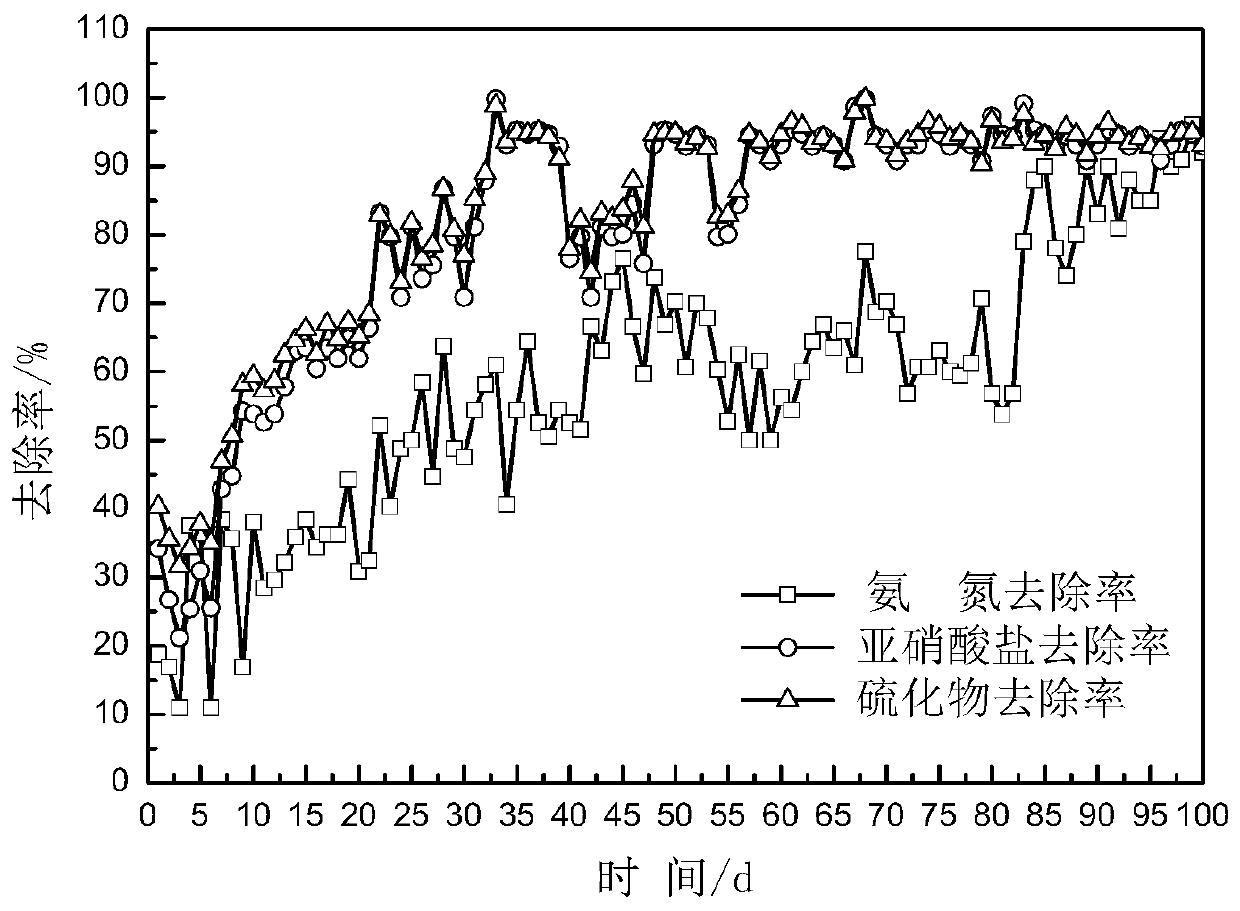

[0055] This embodiment provides a device and method for co-processing ship exhaust gas washing waste liquid and ship domestic sewage. The co-processing device includes a reactor shell 17, which is provided with a liquid inlet I8, a liquid inlet II2 and a liquid outlet 6, and the reactor shell 17 is provided with a heterotrophic reaction zone 12 connected in sequence. , the buffer zone 13 and the autotrophic reaction zone 14, the volume of the heterotrophic reaction zone 12 and the autotrophic reaction zone 14 is the same, the overflow port 16 is provided with the buffer zone 13 on the top of the heterotrophic reaction zone 12 and communicates with the buffer zone 13, and the overflow port 16 is vertical The height is 1.5cm, the lower part of the buffer zone 13 communicates with the autotrophic reaction zone 14, and the upper ends of the heterotrophic reaction zone 12 and the autotrophic reaction zone 14 are all provided with vent holes 3; The liquid port II2 is connected with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com