Method for preparing shell porcelain by using shells and shell porcelain

A technology of shells and shell powder, which is applied in applications, household utensils, clay products, etc., can solve the problems of narrow firing range, complicated preparation process, and large firing deformation, so as to save calcination energy consumption, simplify the process flow, and improve The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for preparing shell porcelain from shells, wherein the raw material components of the shell porcelain include 25% shell powder, 20% albite, 15% alumina-silicate spinel, 5% silica powder, Yunnan mud 30%, Chaozhou black mud 5%, shell powder particle size less than 5mm, silica powder particle size less than 2μm, and the SiO 2 The content is about 99.5%.

[0056] The method for preparing shell porcelain from shells comprises the following steps:

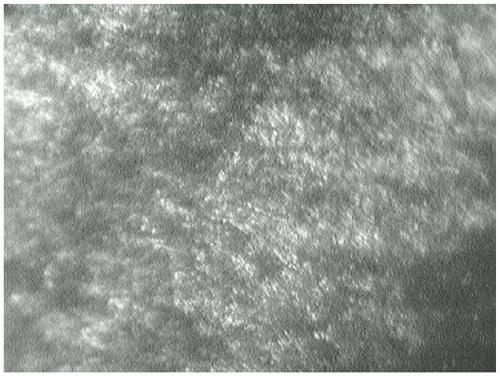

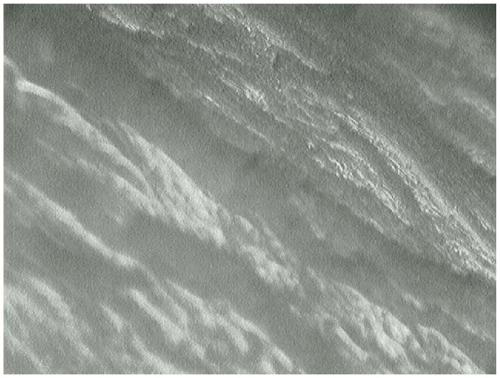

[0057] S11. Clean the sand and sludge remaining on the surface of the shell to make the surface of the shell clean, and take samples to scan the surface of the shell with SEM. The specific scanning results are as follows figure 1 As shown; then the shells were soaked in acetic acid solution with a mass concentration of 0.4%, and the soaking time was 2.0min. After soaking, the shells were taken out, and the soaked samples were taken for SEM scanning. The results were as follows: figure 2 As shown, the subsequently soake...

Embodiment 2

[0067] A method for preparing shell porcelain from shells, wherein the raw material components of the shell porcelain include 25% shell powder, 25% albite, 14% aluminum silicon spinel, 6% silica powder, Yunnan mud 28%, Chaozhou black mud 2%, shell powder particle size less than 5mm, silica powder particle size less than 2μm, its SiO 2 The content is about 99.5%.

[0068] The method for preparing shell porcelain from shells comprises the following steps:

[0069] S21. Clean the residual sand and sludge on the surface of the shell to make the surface of the shell clean, then soak the shell in an acetic acid solution with a mass concentration of 0.5%, and the airtight soaking time is 1 min. After soaking, take out the shell and pulverize the shell to obtain The particle size of shell powder is not greater than 5mm;

[0070] S22. Weigh 25kg shell powder (from shell consumption, particle size not greater than 5mm), 25kg feldspar, 14kg aluminum silicon spinel, 6kg silicon micropow...

Embodiment 3

[0079]A method for preparing shell porcelain from shells, wherein the raw material components of the shell porcelain include 20% shell powder, 25% feldspar, 10% aluminum silicon spinel, 10% silicon micropowder, Yunnan mud 30%, Chaozhou black mud 5%, shell powder particle size less than 5mm, silica powder particle size less than 2μm, its SiO 2 The content is about 99.5%.

[0080] The method for preparing shell porcelain from shells comprises the following steps:

[0081] S31. Clean the residual sand and sludge on the surface of the shell to make the surface of the shell clean, then soak the shell in an acetic acid solution with a mass concentration of 0.3%, for 1.5 min, take out the shell after soaking, and pulverize the shell to obtain The particle size of shell powder is not greater than 5mm;

[0082] S32. Weigh 20kg shell powder (particle size not greater than 5mm), 25kg feldspar, 10kg aluminum silicon spinel, 10kg silicon micropowder (particle size not greater than 2μm, S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com