Preparation method of L-2,4-diaminobutyrate hydrochloride

A technology of diaminobutyric acid hydrochloride and aminobutyric acid is applied in the preparation of carbamic acid derivatives, the preparation of organic compounds, the preparation of cyanide reactions, etc., and can solve the problems of large pollution of three wastes, cumbersome operations, and long routes. Achieve the effect of reducing production costs, reducing three waste emissions, and reducing the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

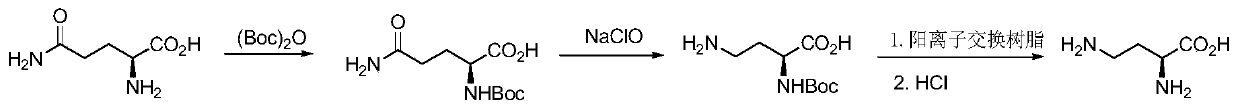

[0032] S1: Add 14.6 g of L-glutamine (0.1 mol) to a 500 mL three-neck flask, add 150 ml of water, 10 g of sodium hydroxide (0.25 mol), stir and clarify, then add 26.2 g of Boc anhydride (0.12 mol), React overnight at room temperature, and monitor the completion of the reaction by spotting the plate;

[0033] S2: Add 4 grams of sodium hydroxide (0.1 mol), and then add 107 grams of 7% sodium hypochlorite (0.1 mol) dropwise at room temperature. After the addition is completed, the temperature is naturally raised for half an hour, and the reaction is monitored by spotting the plate;

[0034] S3: Lower the reaction solution to room temperature, adjust the pH to 5~6 with concentrated hydrochloric acid, desalt through cationic resin exchange resin, and elute with 5% ammonia water as the eluent. After the eluent is concentrated, adjust the pH with concentrated hydrochloric acid From 2 to 3, beat with ethanol to obtain the crude product of L-2,4-diaminobutyric acid hydrochloride, and d...

Embodiment 2

[0036] S1: Add 43.8 g of L-glutamine (0.3 mol) to a 1000 mL three-necked flask, add 450 ml of water, 30 g of sodium hydroxide (0.25 mol), stir and clarify, then add 78.6 g of Boc anhydride (0.12 mol), React overnight at room temperature, and monitor the completion of the reaction by spotting the plate;

[0037] S2: Add 12 grams of sodium hydroxide (0.1 mol), and then add 321 grams of 7% sodium hypochlorite (0.1 mol) dropwise at room temperature. After the addition is completed, the temperature is raised naturally for half an hour, and the reaction is monitored by spotting the plate;

[0038] S3: The reaction solution is lowered to room temperature, and the pH is adjusted to 5~6 with concentrated hydrochloric acid, desalinated by cationic resin exchange resin, and eluted with 5% ammonia water as the eluent, after the eluent is concentrated, the pH is adjusted with concentrated hydrochloric acid From 2 to 3, beat with ethanol to obtain the crude product of L-2,4-diaminobutyric a...

Embodiment 3

[0040] S1: Add 146 grams of L-glutamine (1 mol) to a 3000 mL three-neck flask, add 1500 milliliters of water, 100 grams of sodium hydroxide (2.5 mol), stir and clarify, then add 262 grams of Boc anhydride (0.12 mol), React overnight at room temperature, and monitor the completion of the reaction by spotting the plate;

[0041] S2: Add 40 grams of sodium hydroxide (1 mol), and then add 1070 grams of 7% sodium hypochlorite (1 mol) dropwise at room temperature. After the addition is completed, the temperature is naturally raised to react for half an hour, and the reaction is monitored by spotting the plate;

[0042] S3: The reaction solution is lowered to room temperature, and the pH is adjusted to 5~6 with concentrated hydrochloric acid, desalinated by cationic resin exchange resin, and eluted with 5% ammonia water as the eluent, after the eluent is concentrated, the pH is adjusted with concentrated hydrochloric acid From 2 to 3, beat with ethanol to obtain the crude product of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com