Perylene bisimide derivative functional graphene/carbon nano tube composite thermal conductive thin film and preparation method thereof

A technology of peryleneimide and carbon nanotubes, which is applied in the field of peryleneimide derivative functionalized graphene/carbon nanotube composite heat-conducting film and its preparation, can solve the problem of low longitudinal thermal conductivity, low tensile strength, and preparation problems. Process complexity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

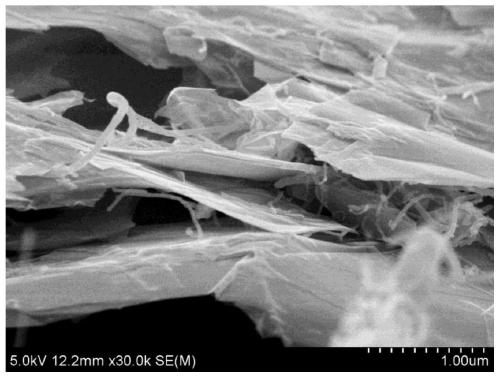

Image

Examples

Embodiment approach 1

[0024] (1) Add 0.5g perylene anhydride, 5.5g polyethylene polyamine, 40mL xylene in a three-necked flask, reflux under N 2 Under protection, the temperature was raised to 80°C. After reacting for 10 hours, the solution was precipitated in 40mL of methanol, and the filter cake was washed with distilled water several times until the filtrate was neutral, and dried overnight at 60°C in a vacuum oven to obtain perylene imide Amine Derivatives (APBI).

[0025] (2) In a 250mL three-neck flask with a reflux device, add 0.8g of multi-walled carbon nanotubes (MWCNTs), then slowly add 120mL of concentrated nitric acid and 40mL of concentrated sulfuric acid, and stir the reaction at 50°C for 12h. After the reaction is completed, the mixed solution is filtered, and repeatedly centrifuged with deionized water to separate until neutral, and carboxylated multi-walled carbon nanotubes (c-MWCNTs) can be obtained.

[0026] (3) Take 1.0 g of graphene slurry with a solid content of 0.05 g, add 1...

Embodiment approach 2

[0028] (1) Add 1.0g perylene anhydride, 11g polyvinylpolyamine, 40mL xylene in a three-necked flask, reflux under N 2 Under protection, the temperature was raised to 80°C. After reacting for 12 hours, the solution was precipitated in 50mL of methanol, and the filter cake was washed with distilled water several times until the filtrate was neutral, and dried overnight at 60°C in a vacuum drying oven to obtain perylene imide Amine Derivatives (APBI).

[0029] (2) In a 250mL three-neck flask with a reflux device, add 0.8g of multi-walled carbon nanotubes (MWCNTs), then slowly add 120mL of concentrated nitric acid and 40mL of concentrated sulfuric acid, and stir the reaction at 50°C for 12h. After the reaction is completed, the mixed solution is filtered, and repeatedly centrifuged with deionized water to separate until neutral, and carboxylated multi-walled carbon nanotubes (c-MWCNTs) can be obtained.

[0030] (3) Take 1.0 g of graphene slurry with a solid content of 0.05 g, add...

Embodiment approach 3

[0032] (1) Add 1.0g perylene anhydride, 11g polyvinylpolyamine, 40mL xylene in a three-necked flask, reflux under N 2 Under protection, the temperature was raised to 80°C. After reacting for 12 hours, the solution was precipitated in 50mL of methanol, and the filter cake was washed with distilled water several times until the filtrate was neutral, and dried overnight at 60°C in a vacuum drying oven to obtain perylene imide Amine Derivatives (APBI).

[0033](2) In a 250 mL three-necked flask with a reflux device, 0.8 g of multi-walled carbon nanotubes (MWCNTs) was added, and then 120 mL of concentrated nitric acid and 40 mL of concentrated sulfuric acid were slowly added, and the reaction was stirred at 50 to 70 ° C for 12 to 24 h. After the reaction is completed, the mixed solution is filtered, and centrifuged and washed with deionized water repeatedly to obtain neutrality to obtain carboxylated multi-walled carbon nanotubes (c-MWCNTs).

[0034] (3) Take 1.0 g of graphene slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com