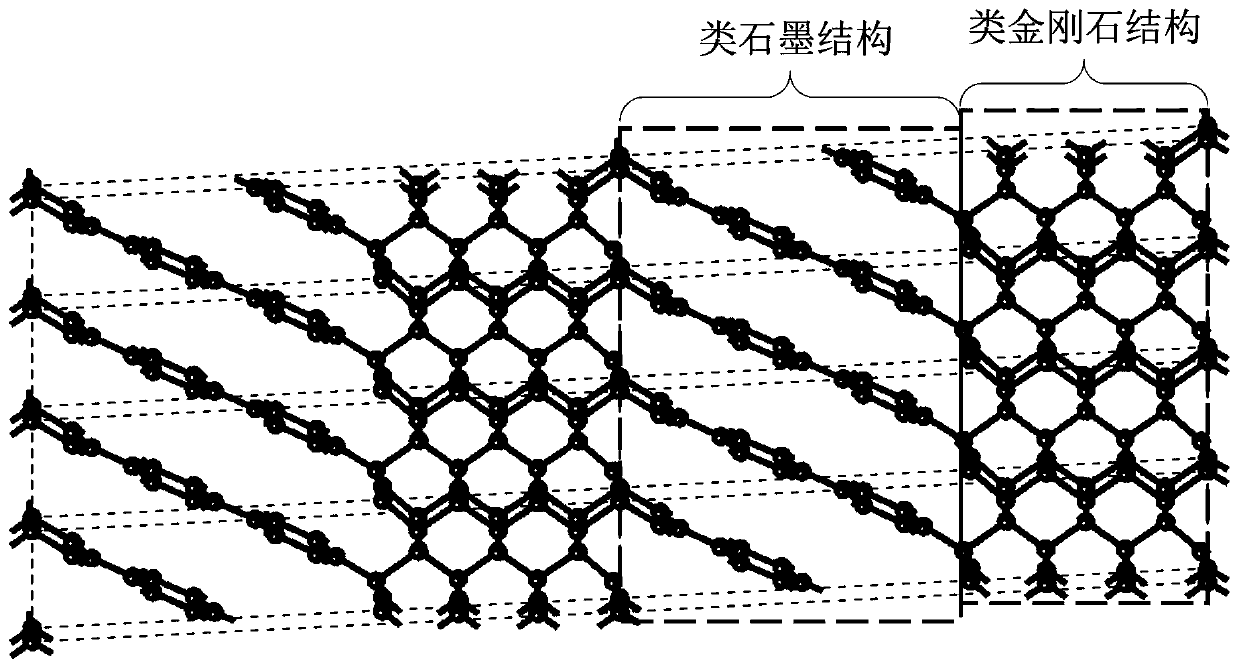

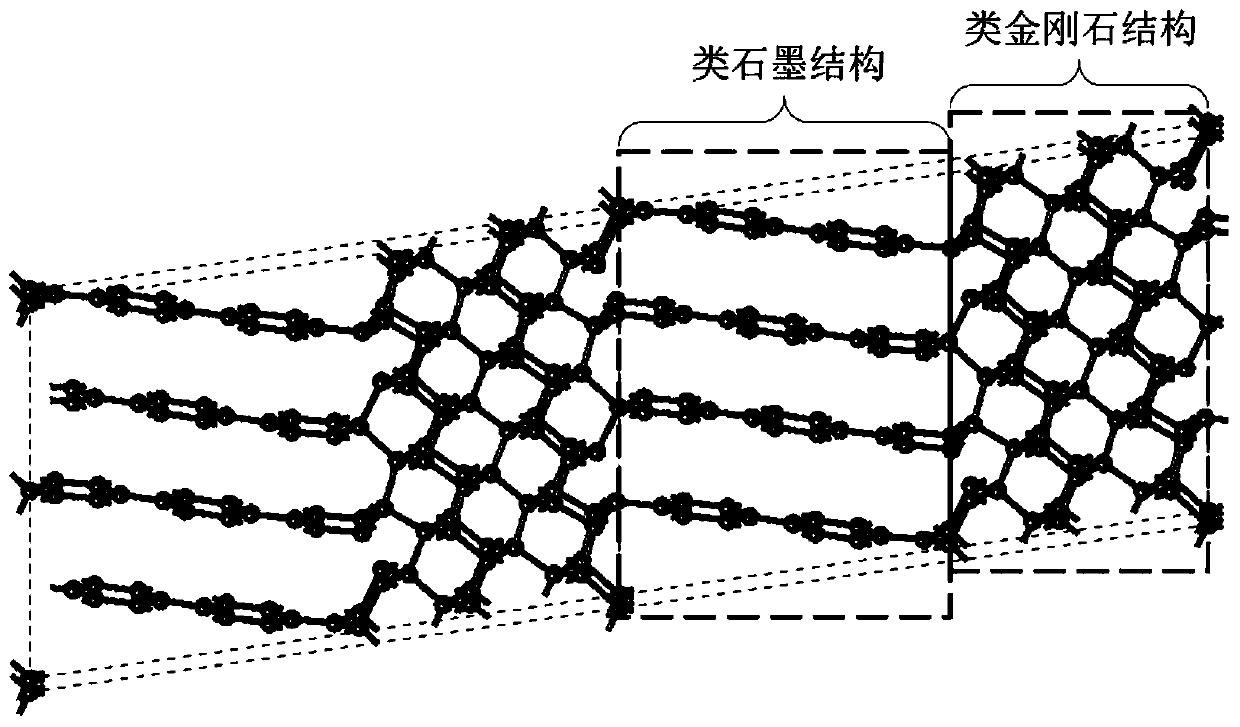

Novel sp2-sp3 hybrid Gradia carbon and preparation method thereof

A sp2-sp3, hybridization technology, applied in the direction of carbon preparation/purification, manufacturing tools, metal processing equipment, etc., to achieve the effects of cheap and easy to obtain, simple operation, and easy control of high-pressure synthesis parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention discloses a novel sp2-sp3 hybridized Gradia carbon and a preparation method thereof. The preparation method comprises the following steps:

[0031] (1) Put one or more sp2 hybrid carbon materials containing sp2 hybrid carbon materials, including graphite, fullerene, carbon nanotubes, amorphous carbon and onion carbon, into a pre-pressing mold, and press the tablet The sp2 hybrid carbon material is prefabricated into a straight cylindrical green body by machine action, and then placed in a vacuum hot-press sintering furnace for pre-sintering. The pre-sintering temperature is 400-1800 ° C, and the pre-sintering time is 10-60 minutes;

[0032] (2), put the sp2 hybridized carbon material body pre-fired in step (1) into the assembly block, then put the assembly block containing the sp2 hybridized carbon material body into a drying oven for drying, and dry The temperature is 100-250°C, and the drying time is 1-3h. ;

[0033] (3) Take out the assembly block in ...

Embodiment 1

[0042] Embodiment 1: Prepare Gradia carbon with graphite as sp2 hybridized carbon raw material

[0043] (1) Put the graphite pre-compression mold, use a tablet press to prefabricate a cylindrical blank for 5-10 minutes under a pressure of 20-40MPa, and then put it into a vacuum hot-pressing sintering furnace for pre-sintering, and the pre-sintering temperature is controlled at Between 1000-1600°C, the pre-burning time is controlled at 20-40min;

[0044] (2), put the sp2 hybridized carbon material body pre-fired in step (1) into the assembly block, then put the assembly block containing the sp2 hybridized carbon material body into a drying oven for drying, and dry The temperature is 180°C, and the drying time is 2 hours;

[0045] (3) Take out the assembly block in step (2) and cool it to room temperature, then put it into a T25 press produced by Rockland Research in the United States for high temperature and high pressure operation, the synthesis pressure is 5-25GPa, and the t...

Embodiment 2

[0048] Embodiment 2: Preparation of Gradia carbon with carbon nanotubes as sp2 hybrid carbon raw material

[0049] (1) Put the carbon nanotubes into the pre-pressed mold, and use a tablet press to prefabricate the cylindrical blank for 5-10 minutes under a pressure of 30-50 MPa, and then put it into a vacuum hot-pressing sintering furnace for pre-sintering, and the pre-sintering temperature Control at 800-1600°C, and control the pre-burning time at 15-40min;

[0050] (2) Put the carbon nanotube body pre-fired in step (1) into the assembly block, and then put the assembly block containing the carbon nanotube body into a drying oven for drying at a drying temperature of 180°C , the drying time is 2h;

[0051] (3) Take out the assembly block in step (2) and cool it to room temperature, then put it into a T25 press produced by Rockland Research in the United States for high temperature and high pressure operation, the synthesis pressure is 7-25GPa, and the temperature is 1000-180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com