A highly efficient and environmentally friendly industrial wastewater treatment system

A technology for industrial wastewater and treatment systems, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of high loss of ammonia and phosphate, low production efficiency of struvite, etc. , to achieve the effect of removing nitrogen and phosphorus and reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

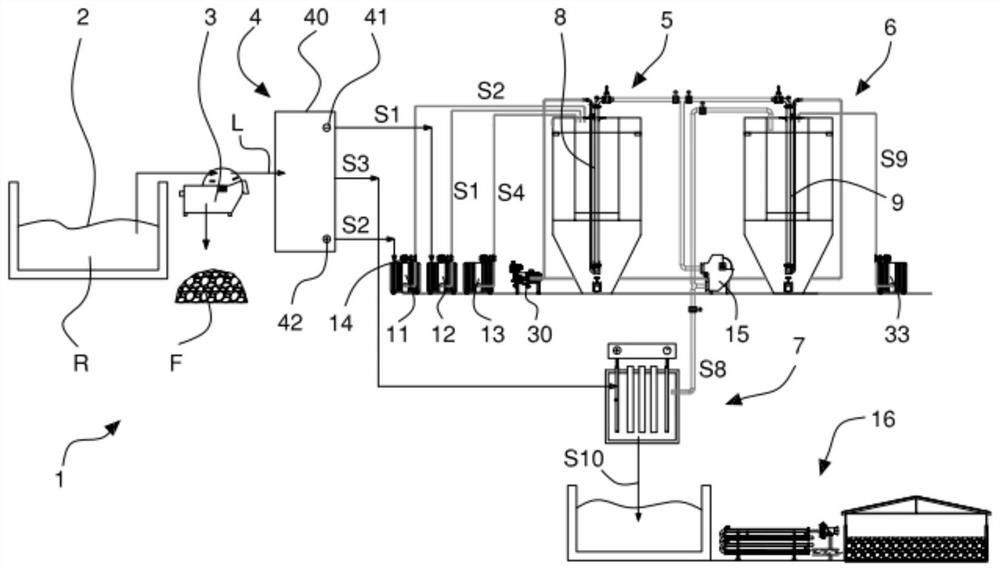

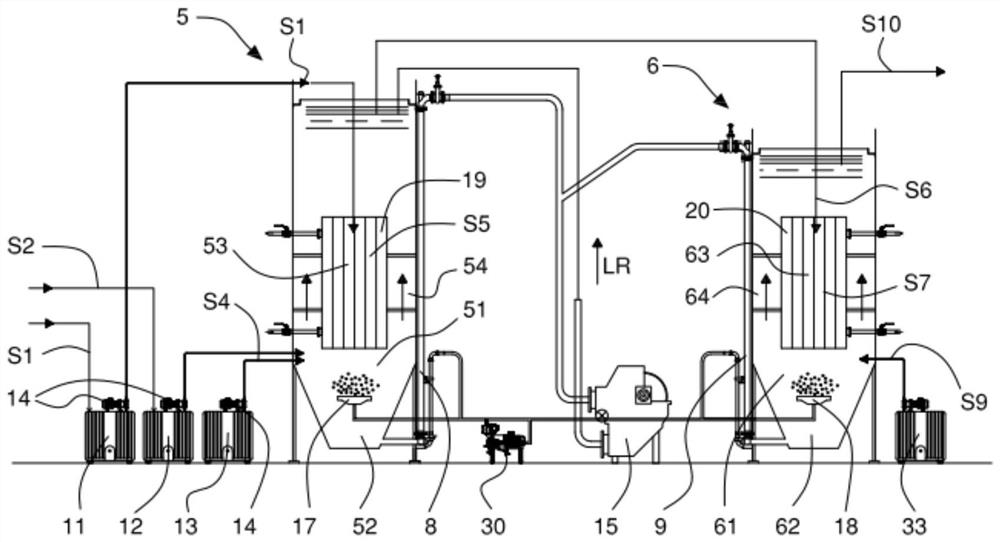

[0031] Such as Figures 1 to 3 , the high-efficiency environmental protection industrial waste water treatment system 1 among the present invention comprises collection tank 2, first separating device 3, extracts solid organic component from described industrial waste water, obtains nitrogen-containing ammonium (NH4+) and phosphate (HPO42-) waste Liquid L.

[0032] A first type of separation device 3 is used to screen and filter material particles that can be larger than 250 microns in size from a liquid stream.

[0033] The solid / liquid separation step performed by the first separation device 3 causes a significant change in the composition of the industrial wastewater R, in particular a reduction in COD (chemical oxygen demand), an increase in ammonia percentage and a reduction in phosphorus.

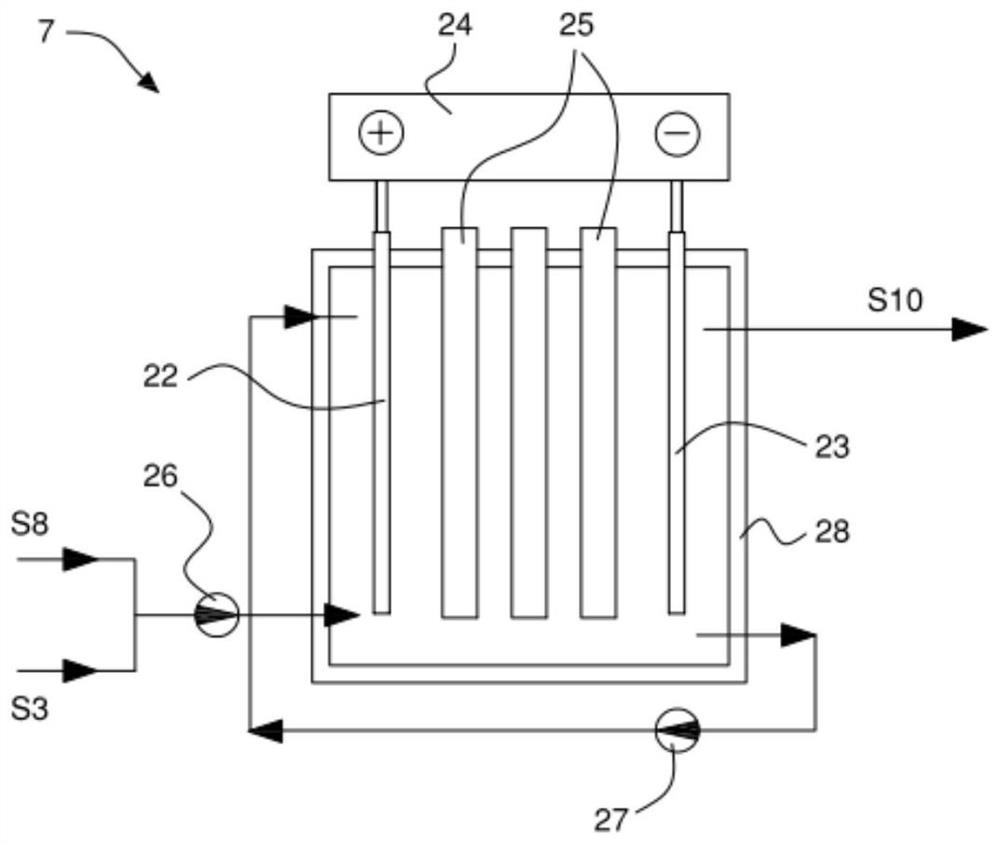

[0034] The treatment system 1 includes a first electrophoretic reactor 4 for treating the waste water L generated by the first separation device 3 . After electrophoresis treatment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com