Direct-writing molded SiCw/SiC composite material and preparation method thereof

A composite material, direct writing technology, applied in the direction of additive processing, etc., can solve problems such as poor strength and toughness, and achieve the effect of short molding cycle, maintaining printing stability, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

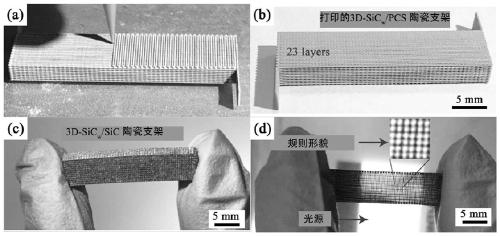

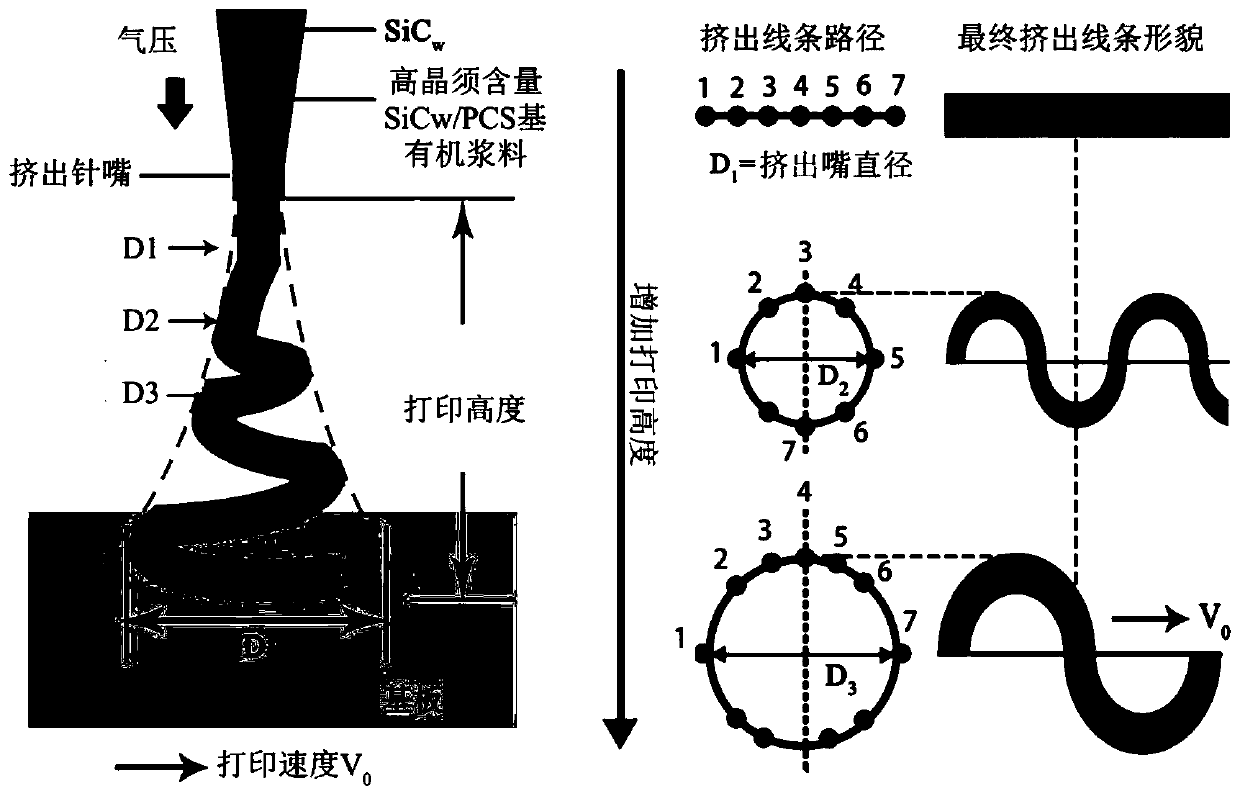

Embodiment 1

[0060] Weigh 8g, 1.6g, 4g and 0.05g of PCS (SiC precursor), SiCw (whisker), SiC powder (inert filler) and methyl methacrylate (dispersant) respectively; put them into polytetrafluoroethylene In the ethylene ball mill tank, add 20g of n-hexane, and add 40g of zirconia grinding balls, the diameter of the ball is 8mm; then ball mill, the speed is 80r / min, the ball milling time is 24h; then the slurry is poured into the beaker, and the poly Divinylbenzene (crosslinking agent) 2.0g, magnetically stirred, and weighed the weight of the solution at this time, accompanied by the volatilization of n-hexane, stop stirring until the solid phase volume content of the slurry is 60.2vol%; The slurry is put into the syringe, and then defoamed by centrifugation. The centrifugal speed is 2000r / min and the centrifugation time is 10min. Then the syringe is taken out, and 3D direct writing equipment is installed to prepare for printing and molding; the printing needle is 160μm, printing The height ...

Embodiment 2

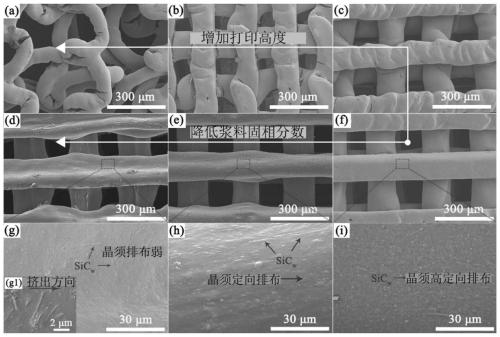

[0062] This example 2 is used to investigate the effect of solid content and printing height on SiC w / SiC-based composite materials, including other parts unchanged, when the printing height is 0.3mm, the solid content is 57.7vol%, 59.9vol% and 62.3vol%. The composite material is prepared when the solid content is 62.3vol% and the printing height is 0.6mm, 0.5mm, 0.4mm and 0.3mm.

[0063] Weigh 8g, 1.6g, 2g and 0.01g PCS (SiC precursor), SiC w (Whisker) and nano SiC powder, methyl methacrylate (dispersant); put it in a polytetrafluoroethylene ball mill tank, add 18g n-hexane, and add 30g zirconia grinding ball, the diameter of the ball is 8mm; Then it was ball milled at a speed of 100r / min and the ball milling time was 12h; then the slurry was poured into a beaker, 1.0g polydivinylbenzene (crosslinking agent) was added, magnetically stirred, and the weight of the solution was weighed. , Along with the volatilization of n-hexane, stop stirring until the solid phase volume content...

Embodiment 3

[0066] Weigh 8g, 1.6g and 0.01g PCS (SiC precursor), SiC w (Whisker) and glyceryl tristearate (dispersant); put it in a polytetrafluoroethylene ball mill tank, add 18g n-hexane, and add 30g zirconia grinding ball, the diameter of the ball is 8mm; then ball milling , The rotation speed is 160r / min, and the ball milling time is 20h; then the slurry is poured into a beaker, 1.0g polydivinylbenzene (crosslinking agent) is added, magnetically stirred, and the weight of the solution at this time is weighed. The n-hexane volatilizes until the solid phase volume content of the slurry is 65vol%, and the stirring is stopped; the slurry is placed in a syringe, and then centrifuged to defoam, the centrifugal speed is 2000r / min, and the centrifugal time is 8min; then the needle Take out the cylinder, install 3D direct writing molding equipment, and prepare for printing; the printing needle nozzle is 160μm, the printing height is 0.4mm, the printing speed is 8mm / s, the printing gas and air pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com