Preparation method of industrial hemp extract

A technology of industrial hemp and extracts, applied in the preparation of organic compounds, chemical instruments and methods, medical preparations containing active ingredients, etc., can solve problems such as toxicity, harm to experimenters and the environment, and cumbersome processes, and achieve reagent Environmental protection, easy access to equipment and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

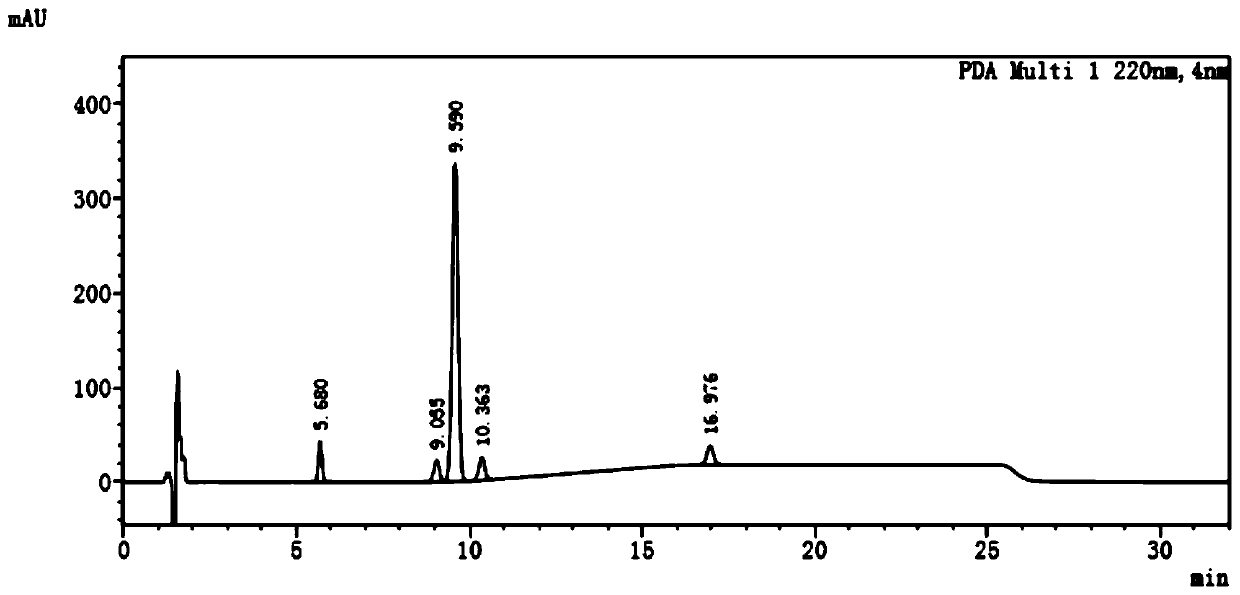

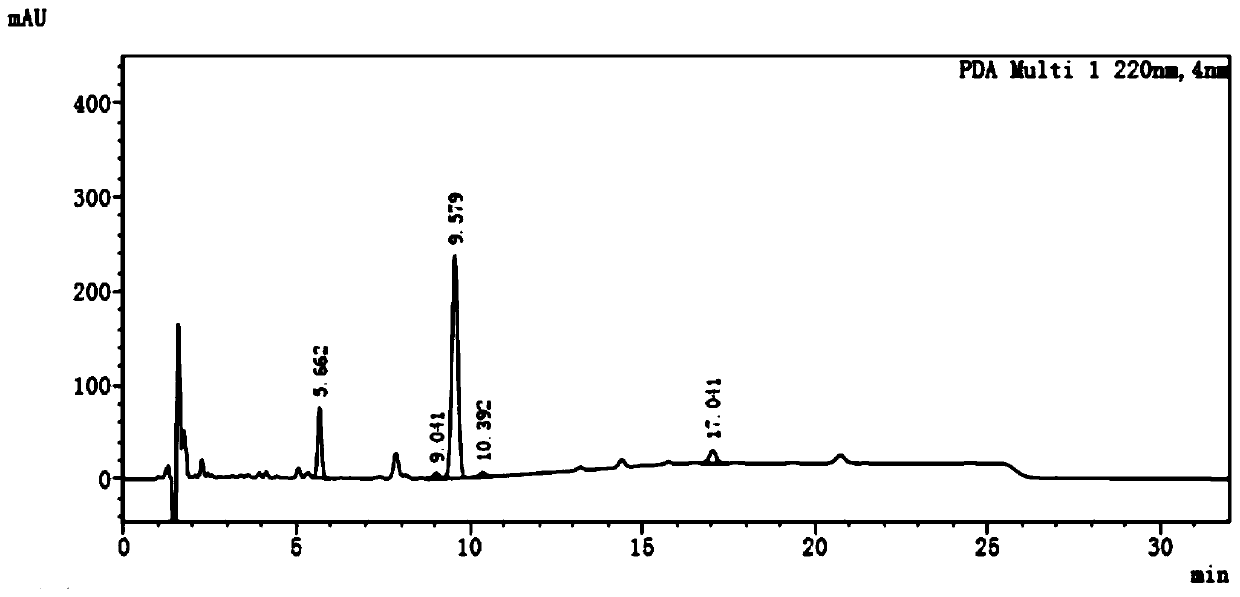

[0076] Preparation of the reference substance solution: Accurately weigh the CBD reference substance, add methanol to make a 0.15mg / mL reference substance solution; Accurately weigh the THCV reference substance, add methanol to make a 0.01mg / mL reference substance solution, and get it; accurately weigh the CBG reference substance, add methanol to make a 0.01mg / mL reference substance solution, and get it; Take tetrahydrocannabinol reference substance, add methanol to make 0.01mg / mL reference substance solution, and obtain it.

[0077] Preparation of the test solution: Take 1.1mL of the sample solution, add methanol to make it up to 25mL, filter it with a microporous membrane (0.45μm), and take the subsequent filtrate to obtain the final product.

[0078] Determination method: Precisely draw 10 μL each of the reference substance solution and the test solution, inject it into the liquid chromatograph, measure it, and obtain it.

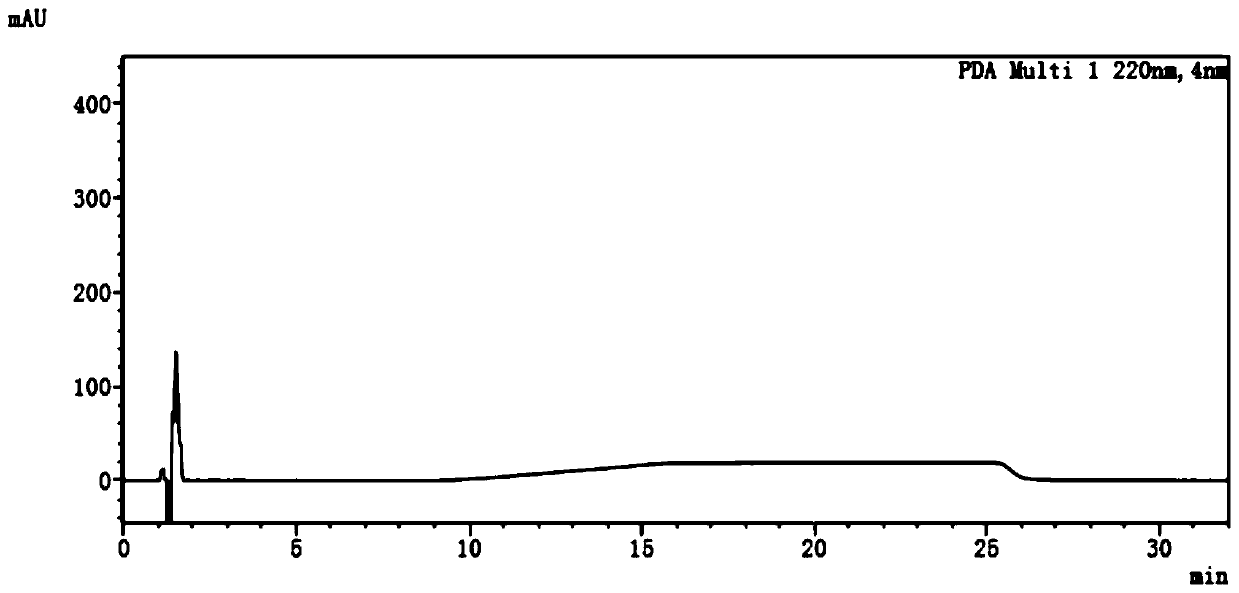

[0079] figure 1 Shown is the blank control (95% ...

Embodiment 1

[0081] (1) Grind the flower and leaves of industrial hemp, pass through a No. 1 sieve, bake at 100°C for 200 minutes, take a certain amount of the flowers and leaves of hemp after roasting, and add 95% of the hemp flowers and leaves according to the material-to-liquid ratio of 1:8 (w / v) Ethanol, stirring and extracting at room temperature twice, each time for 1 hour, filtering, combining the extracts, centrifuging, concentrating the centrifuged filtrate under reduced pressure (65°C, -0.08~-0.09Mpa) to the extract, adding 3 times the equivalent of medicinal materials for purification water, keep stirring at 75°C for 30 minutes, put it in a liquid separation tank and cool to room temperature, add sodium carbonate and stir to dissolve, leave it at room temperature for 3 hours, separate the upper layer, and obtain the crude cannabis extract.

[0082] (2) Stir and dissolve the obtained cannabis crude extract with 95% ethanol of 3 times the equivalent of the medicinal materials, add ...

Embodiment 2

[0084] (1) Grind the flower and leaves of industrial hemp, pass through a No. 3 sieve, bake at 200°C for 60 minutes, take a certain amount of the flowers and leaves of hemp after roasting, and add 90% according to the ratio of material to liquid: 1:10 (w / v) Ethanol, stirred at room temperature and extracted twice, each time for 1 hour, filtered, combined extracts, centrifuged, concentrated the centrifuged filtrate under reduced pressure (65°C, -0.08~-0.09Mpa) to the extract, added 2 times the equivalent of medicinal materials for purification Water, heat preservation and rotation at 70°C for 30 minutes, perform butterfly centrifugation and layering of the transsolution solution at a speed of 5000 rpm, separate the upper layer, and obtain the crude cannabis extract.

[0085] (2) Stir and dissolve the obtained cannabis crude extract with 95% ethanol which is 3 times the equivalent of the medicinal material, add 0.05 times the diatomite equivalent of the medicinal material, stir a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com