A kind of infrared selective radiation cooling nano functional composition and preparation method thereof

A nano-functional and selective technology, applied in the field of thermal radiation, can solve the problems that high-performance radiation coolers have not yet appeared, cannot be mass-produced, and the cooling effect of radiation coolers is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

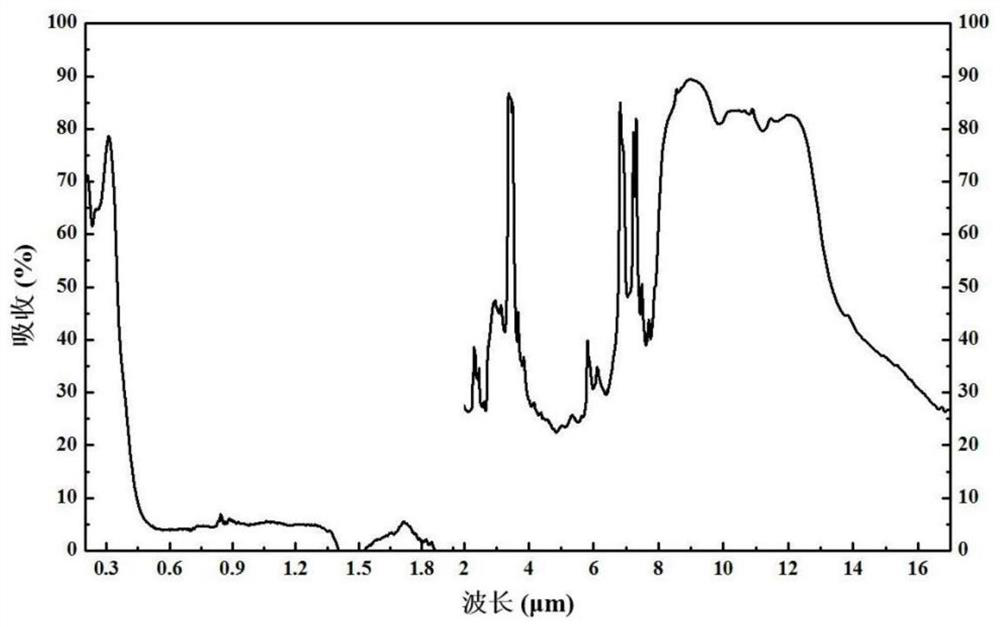

Image

Examples

Embodiment 1

[0020] This embodiment discloses an infrared selective radiation cooling nano-functional composition and its preparation process, including the following steps:

[0021] (a) According to the stoichiometric ratio of rare earth lanthanum silicate compound SiO 2 -La 2 o 3 -0.5Na 2 O, accurately weigh 30g of nano-silica (50nm, commercially available), 324.9g of lanthanum nitrate and 85g of sodium nitrate, dissolve them in a mixed solution of ethanol and water, evaporate the solvent in a water bath with stirring at 70°C to obtain a gel, and Heat treatment for 6 hours to obtain calcined rare earth lanthanum silicate powder, heat treatment at 700° C. for 12 hours to obtain rare earth lanthanum silicate compound with an average particle size of 106 nm.

[0022] (b) According to the chemical formula of calcium molybdate CaMoO 4 , Accurately weigh 82g of calcium nitrate and 170g of ammonium dimolybdate, and dissolve them in deionized water. Configure 8% citric acid solution, add it...

Embodiment 2

[0025] This embodiment discloses an infrared selective radiation cooling nano-functional composition and its preparation process, including the following steps:

[0026] (a) According to the stoichiometric ratio of rare earth lanthanum silicate compound SiO 2 -1.5Sm 2 o 3 -0.25Na 2 0, accurately weigh 24g nanometer silicon dioxide (50nm, commercially available), 134.5g samarium nitrate and 42.5g sodium nitrate, dissolve in the mixed solution of ethanol and water, evaporate the solvent under the stirring condition of 70 ℃ in a water bath to obtain a gel, at 150 ℃ heat treatment for 3 hours to obtain rare earth lanthanum silicate calcined powder, and heat treatment at 900 ℃ for 3 hours to obtain a rare earth lanthanum silicate compound with an average particle size of 115nm.

[0027] (b) According to the chemical formula of calcium molybdate MgMoO 4, Accurately weigh 72.2g of magnesium nitrate and 85g of ammonium dimolybdate, and dissolve them in deionized water. Configure ...

Embodiment 3

[0030] This embodiment discloses an infrared selective radiation cooling nano-functional composition and its preparation process, including the following steps:

[0031] (a) According to the stoichiometric ratio of rare earth lanthanum silicate compound SiO 2 -1.5La 2 o 3 -0.5Na 2 0, accurately weigh 30g nano-silica (30nm, commercially available), 487.4g lanthanum nitrate and 42.5g sodium nitrate, dissolve in the ethanol-water mixed solution, evaporate the solvent to obtain a gel in a water bath at 80°C with stirring, and obtain a gel at 120 ℃ heat treatment for 6 hours to obtain rare earth lanthanum silicate calcined powder, and heat treatment at 650 ℃ for 12 hours to obtain a rare earth lanthanum silicate compound with an average particle size of 94nm.

[0032] (b) According to the chemical formula of calcium molybdate CaMoO 4 , Accurately weigh 82g of calcium nitrate and 170g of ammonium dimolybdate, and dissolve them in deionized water. Configure 8% citric acid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com